aviation

Number one in China and a major player in Asia

China - Zhuhai

06.2018 | mins reading time

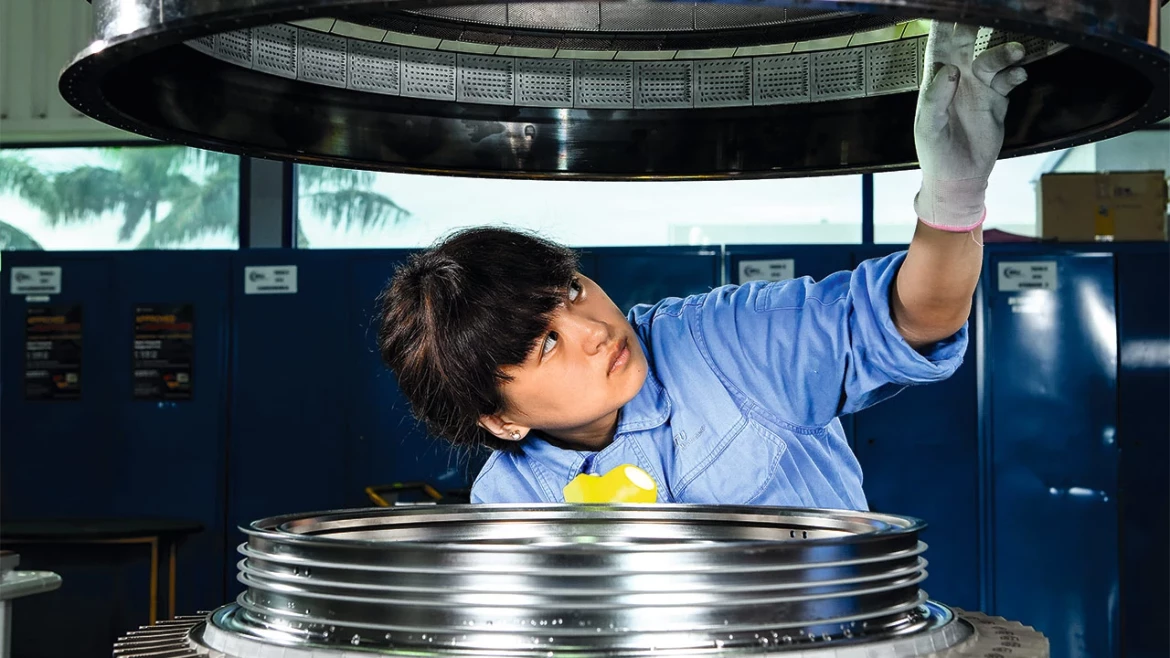

Experts for V2500 and CFM56 engines

When Frank Bodenhage, president & CEO of MTU Maintenance Zhuhai, glances at the clock, it reads 11 a.m. local time in the Chinese special economic zone. That’s 4 a.m. in central Europe. Bodenhage is satisfied: his team is on the point of successfully completing another V2500-A5 maintenance job. The “-A5” is the youngest and also most widespread member of the V2500 engine family, which powers the Airbus A320. Worldwide, its average age is a little over eight years. In terms of maintenance, this means the first full shop visits are still pending or have only recently taken place.

A V2500 engine undergoes a thorough inspection and overhaul at around every 15,000 to 30,000 flying hours. Regulatory requirements stipulate that specific components must be completely replaced, while others are closely inspected and repaired. The focus is always on ensuring that the strict safety regulations for aircraft engines are complied with at all times, as well as on restoring engine efficiency. With the experience gathered from over 1,000 V2500 shop visits under their belts, this is no problem for the engineers from MTU Maintenance Zhuhai. The older an engine is, the greater the depth of repair—in other words the degree to which it is taken apart, examined, repaired and re-assembled during a shop visit. MTU’s engineers in Zhuhai can draw on a high-tech pool of machinery, including a state-of-the-art test cell for subsequently testing the engine.

Apart from the V2500, the Zhuhai experts are no less experienced in maintaining the CFM56 engine: the portfolio includes the CFM56-3, -5B and -7B models, of which MTU’s engineers have overhauled well in excess of 1,000 to date.