aviation

Real networkers: MTU’s engineering experts

USA - Rocky Hill

06.2018 | mins reading time

Rocky Hill, Connecticut, is a peaceful town in a region famous for its verdant pastures, clear-flowing rivers, and the magnificent display of color associated with New England’s Indian summer. But this natural beauty was not the reason why MTU Aero Engines North America (AENA) chose this location: the decisive factor was its proximity to the Pratt & Whitney headquarters in East Hartford, Connecticut. This engine manufacturer is one of MTU’s closest partners. “Our collaboration with Pratt & Whitney plays an essential role in the work we do. The company is not only a partner in new engine development programs but also a major customer for our engineering services,” says Neeraj Rai, business development manager at MTU AENA.

A diverse portfolio of services

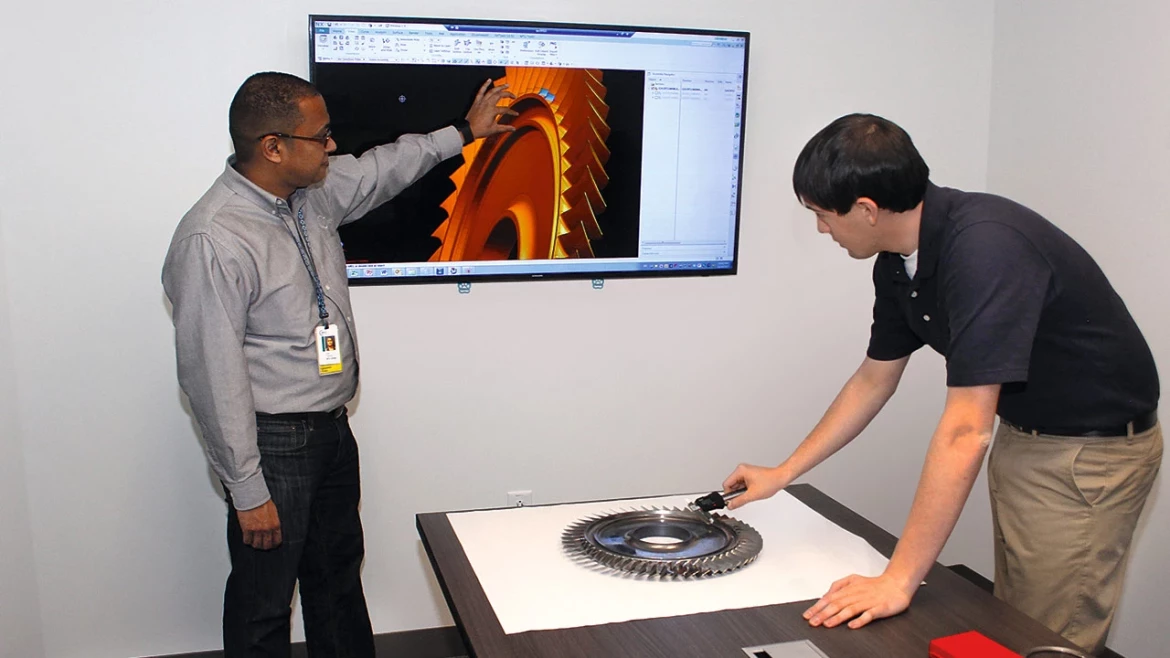

MTU’s U.S. subsidiary is home to a wealth of engineering know-how and experience. “The design team we have built up in the United States develops innovative solutions, creates simulations of everything from discrete components to an entire complex system, and is capable of managing a whole project from end to end. Our company does everything it can to meet the customer’s requirements,” says Rai.

The great advantage is that the people at MTU speak the same language as their customers. “As well as being well versed in the art and science of engineering, we also understand the reality of other challenges such as time pressure, cost sensitivities, export control requirements, and quality imperatives,” says Jonathan Leach, president and CEO of MTU AENA. “Our customers turn to us for a variety of reasons, a major one being MTU’s outstanding reputation as an engineering services provider.” MTU AENA’s team of engineering professionals has extensive experience in everything from conceptual design, detail design, project management and test/validation from entry-into-service through post-service support. Engineers at AENA recently identified a cost savings of $700,000 to a key customer by implementing an automation tool within their TeamCenter environment. In the Aftermarket Engineering services area, AENA has leveraged its valuable knowledge of repair writing for aerospace components to develop unique repairs and manuals for a customer in the industrial aero-derivative engine business.