people

Training at MTU: Career springboard

Traditional apprenticeships or dual work-study programs: MTU Aero Engines offers a wide range of attractive and practical training opportunities.

author: Thorsten Rienth | 6 mins reading time published on: 01.07.2020

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

Here’s a welcome headline during this difficult time: “In spite of the coronavirus crisis, we are not reducing the number of training opportunities we offer.”

Apprenticeships at MTU – Further information can be found here

For Manfred Hörmann, Head of Training at MTU Aero Engines in Munich, this news makes perfect sense. “Once the crisis is over, we want to recover as quickly as possible,” he explains. “That will require highly qualified people with excellent training.” He notes that the past few weeks have naturally seen repeated attempts to calculate the scale of the workforce that will be required for the foreseeable future. But the company never wavered from its stance of investing in the future.

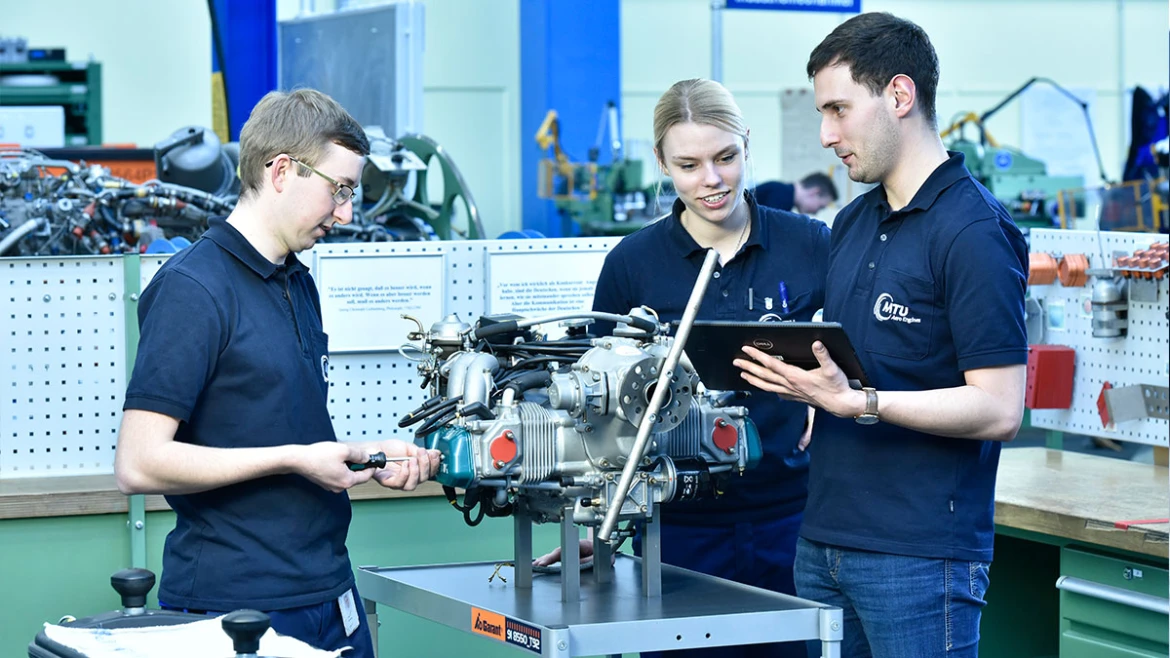

So this summer, Germany’s leading engine expert is once again advertising a long list of training opportunities to start in fall 2021. Industrial mechanics and aircraft maintenance engineers remain in highest demand, followed by mechatronics engineers, surface coaters and warehouse logistics professionals. There are around 15 dual work-study spots available.

Training lasts three to three-and-a-half years, in which time the new colleagues get to know the whole company, Hörmann says. “We’re talking about equipping people for working life.” Or, in other words, for their careers. He points out that training at MTU is clearly a career stepping-stone. “The majority of trainees end up with a permanent employment contract once they’re finished,” Hörmann says.

MTU provides training for young people at all three of its German sites. This alternates between practical experience in the workplace and the learning of background knowledge, either at a training college as in a traditional apprenticeship or at the vocational academy or university as part of our dual work-study programs.

Taking off – and helping people take off

Markus Voag himself once trained as an aircraft mechanic at MTU, specializing in engine technology. “MTU was and still is the only company in a wide radius that offers training in this field.” These days, he still goes in and out of the training shop every day—only now he is a trainer.

He says his fascination for the product hasn’t diminished in all these years. “Engines are literally what make people take off to go on their holidays or business trips. I doubt there’s any other area of work where you can assume greater responsibility.”

Attractive and practical: Dual work-study program at MTU and partner university

Application procedures for the dual work-study program, the second pillar of MTU’s training operations, will also start in the summer. “Dual work-study courses combine academic study at the partner university with the practical application in the workplace of what has been learned,” explains Carolin Hesse, the human resources manager in charge of the dual work-study program. “They are an attractive and practical alternative to ‘pure’ college or university studies, including the option of international placements.”

“MTU is currently in the middle of rolling out digitalization across all corporate divisions,” Hesse says, “and that’s something we can clearly see in the dual work-study courses in commercial areas, business informatics and business engineering.” In terms of content, however, this topic also changes our courses in technical areas. Here, MTU offers a dual mechanical engineering program, with participants specializing either in production and management or in production.

The program alternates between theory at university and practice at MTU. “During their practical assignments at MTU, the students are firmly integrated into each of the departments they pass through, working independently on projects. At the same time, they get a realistic picture of daily working life.” Depending on their field of study, they graduate with the internationally recognized title of Bachelor of Engineering or Bachelor of Science—and usually join MTU directly thereafter in a permanent position.

You can find out what our apprentices and dual students have to say about it here:

Verena Graßl, 22, dual student of business engineering in the sixth semester (MTU Aero Engines / DHBW Stuttgart)

“Business engineers often form the interface between engineers and economists, for example ensuring that projects address both technical and business administration issues in the best possible way. At MTU, I’m currently working in purchasing, but before that I worked in sales, including spending two months in Madrid. Getting to rotate through the departments is a huge advantage, because you soon get a very clear feel for what you like. A dual work-study program can sometimes be quite stressful, I don’t want to hide that. For example, I have to move between Stuttgart and Munich every three months. But over the past three years I’ve also developed enormously—personally, professionally and in terms of independence. And the dual work-study program is also financially attractive. So is the likelihood of being taken on full-time: in the fall, I’ll be starting a permanent position in engine program management in the order management department.”

Kornelius Krech, 20, dual student of mechanical engineering in the fourth semester, (MTU Aero Engines / DHBW Friedrichshafen)

“As a mechanical engineer specializing in production and management, I will go on to work in key positions in MTU’s production operations. These will let me apply my knowledge of production engineering and production management. Of course, the dual work-study program is a full-time job. But when I complete it next year, I will have gotten to know all the areas at MTU that are essential for my future career from a practical perspective: engine assembly, maintenance, development and production. The latter would also be my preferred department for a position to take over. I really like the combination of practice and theory—I get to apply the things I learn at university directly in the teams I work with at the company. At the same time, I get a completely objective impression of the company, its corporate culture and management styles.”

Simon Zacherl, 17, industrial trainee aircraft maintenance engineer, first year of apprenticeship

“I came to MTU for a one-week student internship in engine assembly. That was in the summer between 8th and 9th grade. After that week, I absolutely knew that this was the company I wanted to work for later! I find it unbelievably fascinating to think of all that power in the engines. So I applied for an apprenticeship as an aircraft maintenance engineer before I finished secondary school—and got a letter of acceptance right away. However, as an apprentice you start out at a slightly lower level, namely with the basics of metalworking. What I really like about the MTU training shop is the flat hierarchies. Some of the trainers are only a couple of years older than us apprentices. This creates a real sense of community.”

Maresa Meyer, 21, and Maren Schütte, 21, industrial trainee aircraft maintenance engineer

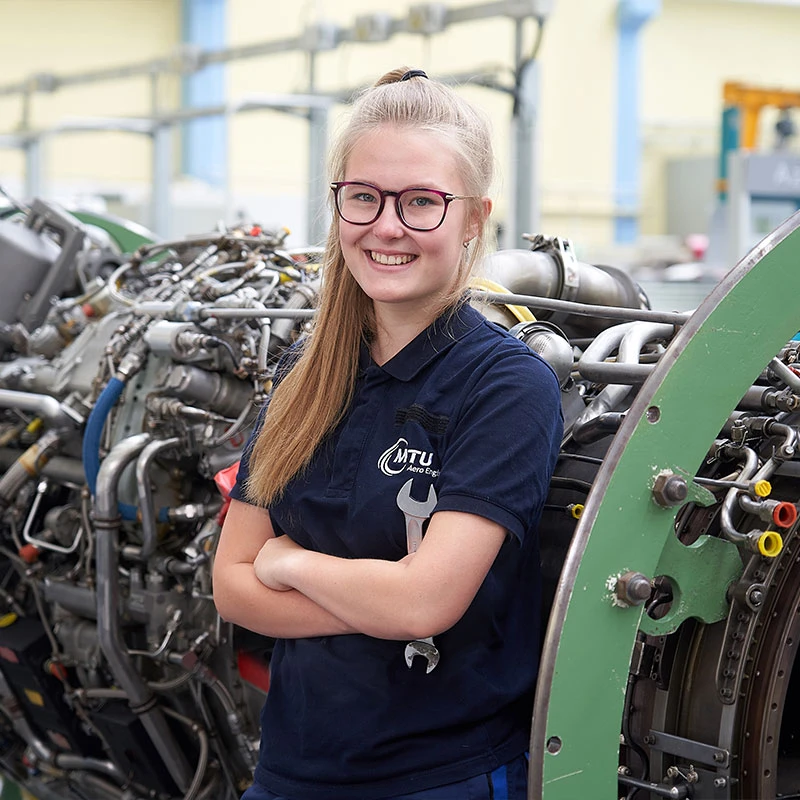

Anna Neumeier, 19, industrial trainee aircraft maintenance engineer, first year of apprenticeship

First of all, I’d like to dispel the prejudice that technical professions are not for women. I feel completely at home in my training as an aircraft maintenance engineer. I’m not even an exception: of the 15 apprentices in my aircraft maintenance engineer class, four of us are women. And it makes no difference to everyday working life anyway. Everyone works together in a really cooperative way. The same is true of the relationship between apprentices and trainers. Most of the time we work independently on our projects, for example on certain components or materials. If we ever get stuck on a task, we can simply go over to the trainers without any fuss. They’re really helpful and very constructive. In the next year of our apprenticeships, we’ll start working on the assembly lines. I’m really looking forward to that.”