people

Behind the scenes at the airport: The apron controller

Natalie Lüth directs aircraft to parking spaces and gets them back to the runway quickly.

author: Andreas Spaeth | 4 mins reading time published on: 07.08.2024

author:

Andreas Spaeth

has been traveling the world as a freelance aviation journalist for over 25 years, visiting and writing about airlines and airports. He is frequently invited to appear on radio and TV programs to discuss current events in the sector.

©Andreas Spaeth

Only a few specially secured doors separate the panorama restaurant on the upper floor of Hamburg Airport, where travelers and visitors help themselves to the buffet, from an inner sanctum of airport operations: apron control. Similar to a ship’s command bridge, this room offers the best view of the airport grounds, with windshield wipers for clear visibility in bad weather. Natalie Lüth has been working here for 30 years. After completing her training as an air traffic controller, the 54-year-old from Hamburg wanted to stay in her hometown and not move to Frankfurt. “If I’d stayed at DFS, the German air navigation service provider, I would’ve had to move away,” she says, “so instead I switched jobs and started working as an apron controller at Hamburg Airport in 1994.” Here in the airport’s own control tower, Lüth helps monitor traffic on the apron and assigns aircraft to taxiways and parking positions. Things can get tight out there, especially at peak times. Efficient processes are essential for making optimum use of the airport’s infrastructure.

Airplanes used to simply taxi in a clockwise direction

Hamburg Airport has only had its own apron control unit since 1992. “Before that, there were no passenger boarding bridges, and aircraft taxied unassisted in a clockwise or counterclockwise direction, depending on the runway in use. For example, the airlines knew that if they were taking off on runway 33, they would taxi clockwise,” Lüth says. “And it used to be the traffic control center that solely assigned the parking areas to arriving aircraft. There was a kind of island here where the planes would park.”

Air traffic at Hamburg Airport soon grew to such an extent, however, that more parking positions were needed. Today, there are almost 50 parking spaces for commercial aircraft and a few more for smaller planes. The airport also had to establish a central authority, apron control, to monitor and coordinate all the taxiing in and out. Lüth was the first female apron controller 30 years ago. “Being the only woman wasn’t always pleasant; some of my colleagues were prejudiced. But times have changed: out of the 21 colleagues I have today, ten of them are women.”

©Andreas Spaeth

View: The apron control offers a prime view of the airport grounds and is even equipped with windshield wipers for clear visibility in bad weather.

Apron control is teamwork

A job like this calls for teamwork. “When volumes are higher, such as on weekdays and at the start of school vacations, we need to have four positions working per shift,” Lüth explains. “Two are apron controllers, who are responsible for ensuring safe, orderly, and rapid movement on the apron. They also see to it that landed aircraft arrive safely at their parking position and that departing aircraft get safely to their taxi stop on the runway.”

Then there are two assistant controllers, who stay on the radio to get all the information coming in from outside and pass it on to the apron controllers sitting next to them. During radio breaks, the assistants inform the controllers about important events and also receive information from them for further processing. Lüth experienced this during her last shift, which just ended. “We had a medical emergency on board an aircraft that had landed. I was informed of this over the radio by the DFS air traffic controller in the tower. I then passed the information on to the assistant controller next to me, who notified the airport fire department, the follow-me driver, and ground traffic services. They all needed to know what was going on.”

©Andreas Spaeth

©Andreas Spaeth

©Andreas Spaeth

Efficiency: By planning ahead, taxiways are used efficiently, and blockages are avoided.

©Andreas Spaeth

©Andreas Spaeth

©Andreas Spaeth

Coordination: Apron controllers coordinate aircraft at the runway-apron border.

Apron control grants permission to taxi to the gate

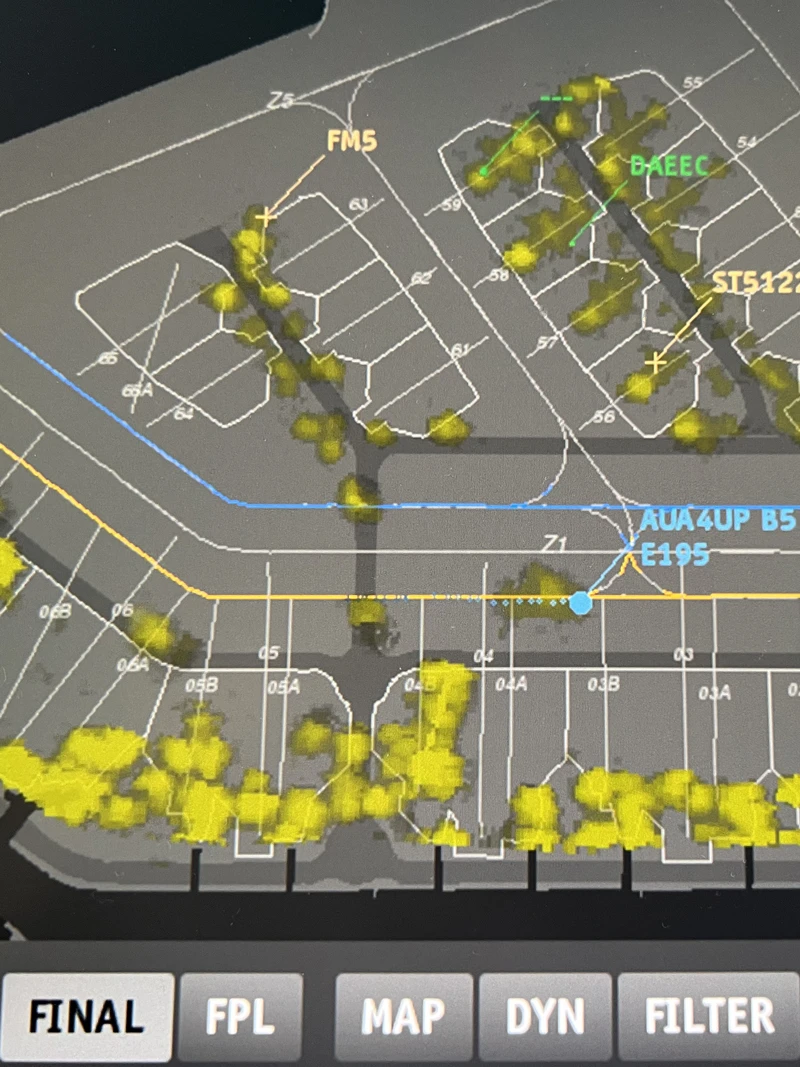

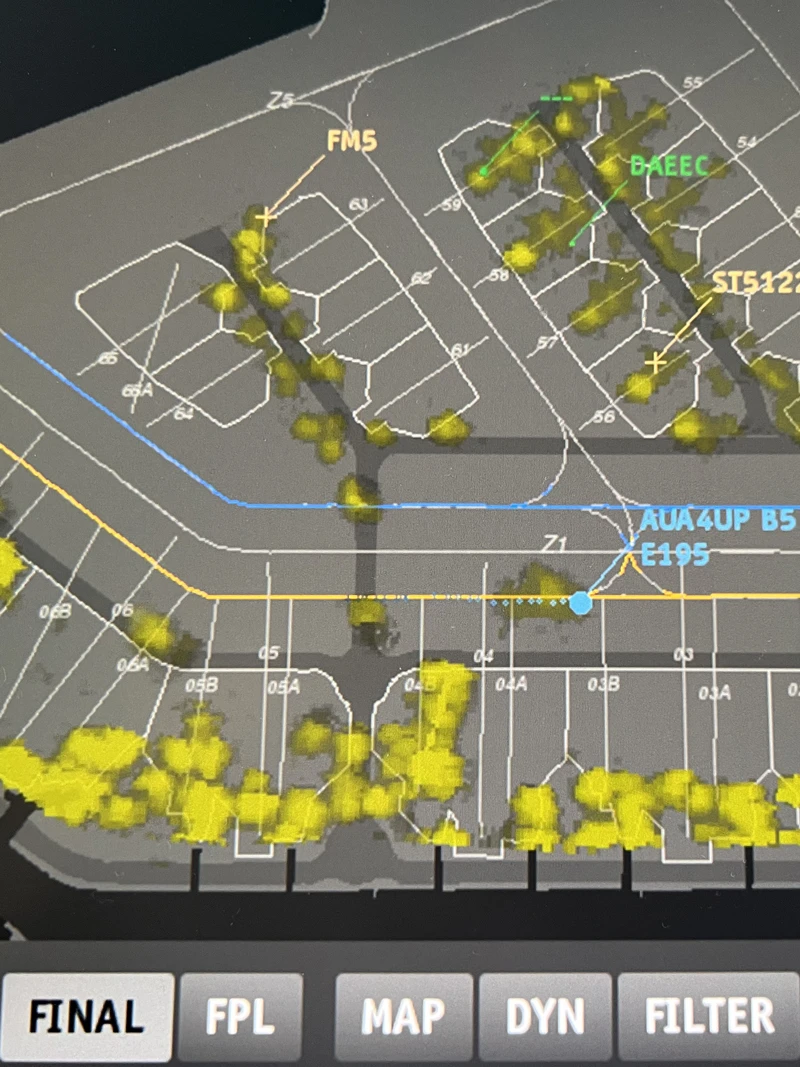

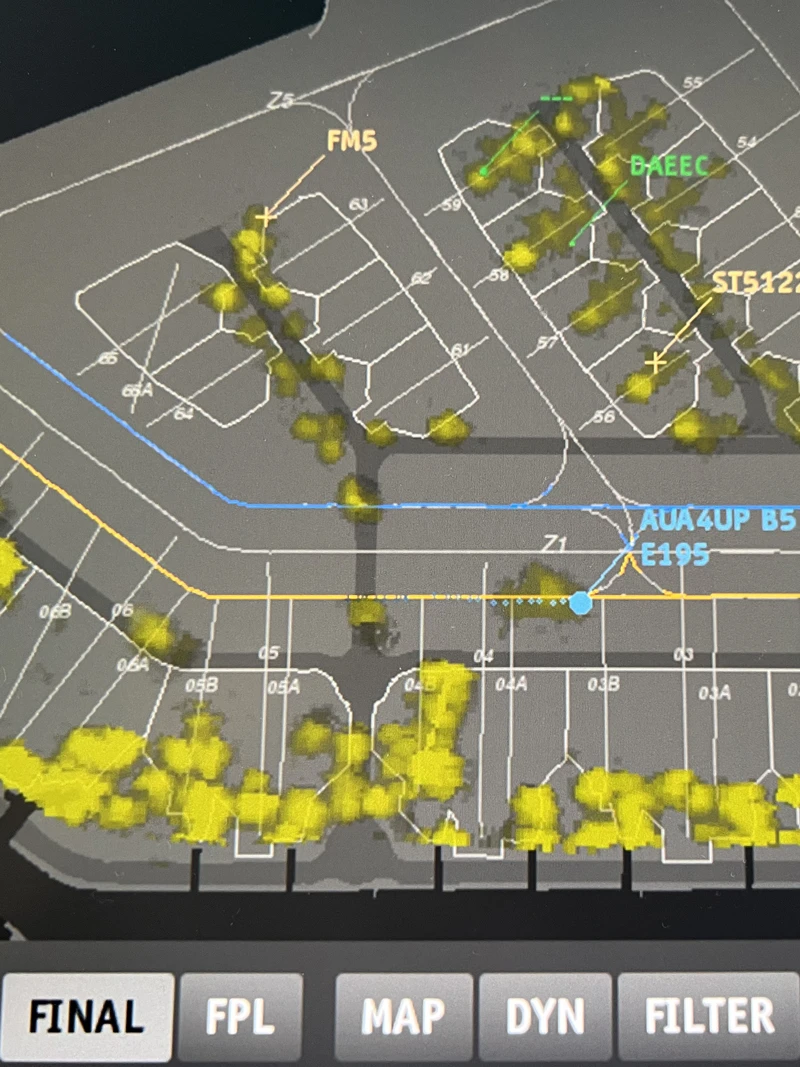

Apron controllers like Lüth work in close coordination with their DFS colleagues up in the tower, who guide the aircraft through the air and along the runways and taxiways until just before they enter the apron. “At the runway-apron border, the tower hands the aircraft over to me on the apron frequency. The pilots also have to stop before they enter my area of responsibility,” Lüth explains. “They have to call me on the radio so I can direct them to the taxiway that leads to their parking position. I can also talk to the DFS colleagues in the tower so that they can perhaps guide the aircraft to me on a different taxiway, to make the taxiing process as efficient as possible.”

Not only do Lüth and her colleagues need to deal with situations as they unfold, but they also need to think ahead. “If we didn’t think beforehand about the best way to manage traffic on the ground, we wouldn’t be able to get the planes to the runway so quickly,” Lüth says, speaking from experience. “Otherwise, there might be other aircraft in the way, or a tug driver trying to move an aircraft could obstruct taxiing.”

“It’s precisely this stress that I enjoy. I like that I sometimes have to kick my concentration into high gear. It’s a challenge to keep on top of my work, but as long as I can do that, I’ll enjoy my job.”

No software can replace mental and manual work

Despite all the computer assistance available today, there’s still no software that can handle this ground coordination. “This work requires the human ability to coordinate. I can see a lot from up here, and can foresee and plan for what will happen next. No software could do that,” Lüth says. “There are already programs for making the process a bit more efficient, but we are ultimately responsible for managing the traffic. Our job involves mental and manual labor.”

Working in apron control makes for an incredibly stressful job, because different situations that have to be resolved at different levels regularly come together at the same time. “It’s precisely this stress that I enjoy,” Lüth says—and it’s been like that for three decades. “I like that I sometimes have to kick my concentration into high gear. It’s a challenge to keep on top of my work, but as long as I can do that, I’ll enjoy my job.”