aviation

Air rescue 24/7: How Germany’s ADAC keeps its fleet ready

Almost everyone in Germany is familiar with the yellow ADAC helicopters. Behind the scenes, it’s the job of ADAC Heliservice specialists to keep these special aircraft well equipped and maintained.

author: Dr. Philipp Bruhns | 5 mins reading time published on: 17.10.2025

author:

Dr. Philipp Bruhns

has been working in corporate communications for over 15 years, and has been self-employed since 2008. Based in Denmark, Bruhns has a doctoral degree in psycholinguistics and as an author specializes in maintenance topics and health and social issues.

©Christian Keller I Airbus Helicopters

A serious traffic accident casts a long shadow over a motorcyclist’s weekend ride: He’s critically injured after a head-on collision. The nearest clinic that specializes in that kind of injury is over 50 kilometers away—and that’s not the only problem. Since the rider’s spine may be injured, he needs to be transported with particular care. This is precisely the kind of mission the H135 from Airbus Helicopters is built for—when it takes off for ADAC Luftrettung, Germany’s air rescue service.

On call all day – in the air in two minutes

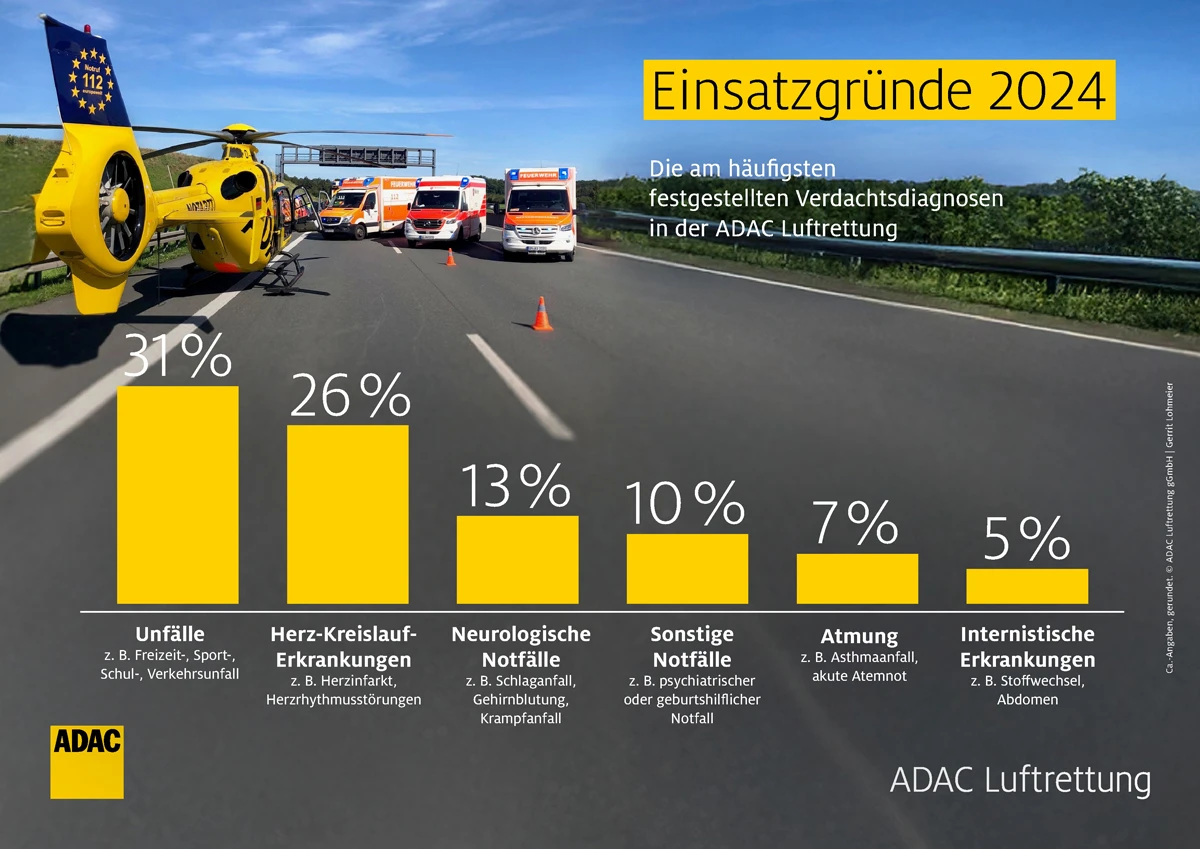

At each of the 38 ADAC centers throughout Germany, a rescue team stands ready every day to tackle any and all eventualities. The team checks the weather data early in the morning and prepares all the relevant mission parameters of the helicopter in the briefing—from takeoff weight to range—so when an emergency strikes, only minimal adjustments are necessary. After the Airbus H135 taxis out of the hangar, its pilot performs a careful inspection. If everything’s in order, it will often take just two minutes from the sounding of the alarm to get airborne. But even after that, teamwork is still essential: The interactions between pilots, emergency doctors, and paramedics are routine and perfectly coordinated. Last year alone, ADAC Luftrettung flew over 49,000 missions—but thankfully they weren’t all as dramatic as the example above: Typical missions include planned transfer flights with intensive medical care, missions to places that are difficult to access, and flights where the emergency is resolved while the helicopter is still on its way to the scene.

©ADAC Luftrettung

Nationwide, ADAC rescue helicopters flew more than 49,000 missions—often life-saving. On average, the aircraft were dispatched to nearly 135 emergencies every day.

The fact that ADAC’s lifesavers can rely on their technology is thanks not only to the robust and sophisticated design of the H135—a real workhorse—but also to the pooled expertise on hand at ADAC Heliservice, the ADAC network’s specialist service subsidiary. The helicopters and their components are maintained at the headquarters (Bonn-Hangelar airfield in Sankt Augustin) as well as at three other sites. All four locations are also responsible for developing tailored modifications to the cockpit and cabin, which are incorporated directly into everyday operations.

Maintaining complex systems around the clock

“Many features of a rescue helicopter aren’t available ex works,” says Sebastian Friese, Technical Director of Maintenance at ADAC Heliservice. Whether it’s the reinforced cabin floor, the particularly easy-to-open rear doors, or the way the medical equipment is installed in a confined space—many features are specially developed and adapted for the requirements of air rescue. Constant operational readiness is paramount: At several stations, the crew is ready to leap into action 24 hours a day, 365 days a year. In this environment, standardized maintenance processes quickly reach their limits. That’s why, between major checks and engine overhauls, the team tries to carry out as much maintenance work as possible directly on-site and without interrupting operations. “Many air rescue stations are located on hospital roofs or in densely populated urban areas. There’s simply no room for large workshops or hangars.”

©ADAC Heliservice

ADAC Heliservice GmbH stands for the highest standards in reliability, cost-efficiency and flight safety—365 days a year.

©ADAC Luftrettung / Matthias Böhl

©ADAC Luftrettung / Matthias Böhl

©ADAC Luftrettung / Matthias Böhl

Agile, quiet and fuel-efficient: The H135 helicopter in Siegen is ideal for urban missions thanks to reduced downwash during takeoff and landing.

Special requirements for the engines, too

The special operating conditions of air rescue also pose challenges for the engines. With flight distances that are comparatively short and landing sites that are often dusty and unpaved, these missions have an impact on engine maintenance intervals. ADAC and other operators want these to be as long as possible in order to keep operational readiness high and costs low. “Rescue flights are a nonprofit activity financed largely by donations. That means our customers—first and foremost ADAC Luftrettung—are under an obligation to operate responsibly,” Friese says. Naturally, flight safety is the top priority. Enabling TBO (time between overhaul) extensions calls for close coordination with the engine manufacturer and the aviation authorities.

ADAC Luftrettung and ADAC Heliservice are setting standards in this area—and MTU Maintenance Berlin-Brandenburg is well aware of that. This is where the H135’s PW206 engines undergo a complete overhaul after every 4,500 flight hours, and also where any repairs that exceed the scope of line maintenance are carried out. The ADAC fleet is under the care of the Pratt & Whitney Canada Customer Service Centre Europe (CSC), a joint venture between MTU Maintenance Berlin-Brandenburg and the Canadian engine manufacturer.

“With its large fleet and many years of experience, ADAC plays a pioneering role in many areas,” says Dr. Philipp Schumacher, Fleet Management Program (FMP) Manager at the CSC. Examples include the retrofitting of special air intake filters or the use of sustainable aviation fuels with the PW206 engines. “ADAC Heliservice relies on continuity in maintenance and thinks long-term. This has made it easier to gain the kind of experience required for things like TBO extensions. In our ongoing collaboration, we’re constantly finding innovative solutions that we can incorporate into future service options.”

Working with a sense of pride

Critical, highly stressed rotating components of the PW206 are one such solution. Due to the short flight cycles in HEMS (helicopter emergency medical services), these components often have to be inspected and, if necessary, replaced before the next shop visit. “Removing and installing these components as part of day-to-day operations requires special expertise that goes beyond normal line maintenance,” explains Jeanne Koitzsch, Head of the PW200 shop at MTU Maintenance Berlin-Brandenburg. “ADAC Heliservice has built up this expertise in close collaboration with us, which enables it to reduce operational interruptions for its fleets and increase operational readiness.” She says that the coronavirus pandemic served as a stark reminder to everyone at the PW200 shop of just how much responsibility they bear as the “rescuers’ helpers,” adding: “Our work continued unabated despite the lockdown because it was an essential service. It’s rewarding to be involved in something that helps save lives when it matters most.”

©Christian Keller I Airbus Helicopters

©Christian Keller I Airbus Helicopters

©Christian Keller I Airbus Helicopters

Proven worldwide: More than 1,440 H135 helicopters are in service with over 300 operators in more than 60 countries—logging over 7.6 million flight hours.

Robust all-around talent: The H135

The Airbus H135 has been manufactured in Donauwörth, Bavaria, since 1996—and has everything it needs for demanding rescue missions. Its two 522 kW PW206 engines, built by Pratt & Whitney Canada, provide reliable thrust even under difficult conditions. Compact, robust, versatile, and technically sophisticated, the H135 is the ideal all-around talent. So it’s no wonder that it’s the most frequently used light rescue helicopter for helicopter emergency medical services, or HEMS—not only in the ADAC fleet but worldwide. Continuous technological advancements have kept this helicopter at the cutting edge: Even if larger models such as the Airbus H145 cover a broader range of missions, the H135 will remain a proven and reliable force in traditional air rescue for the foreseeable future.