aviation

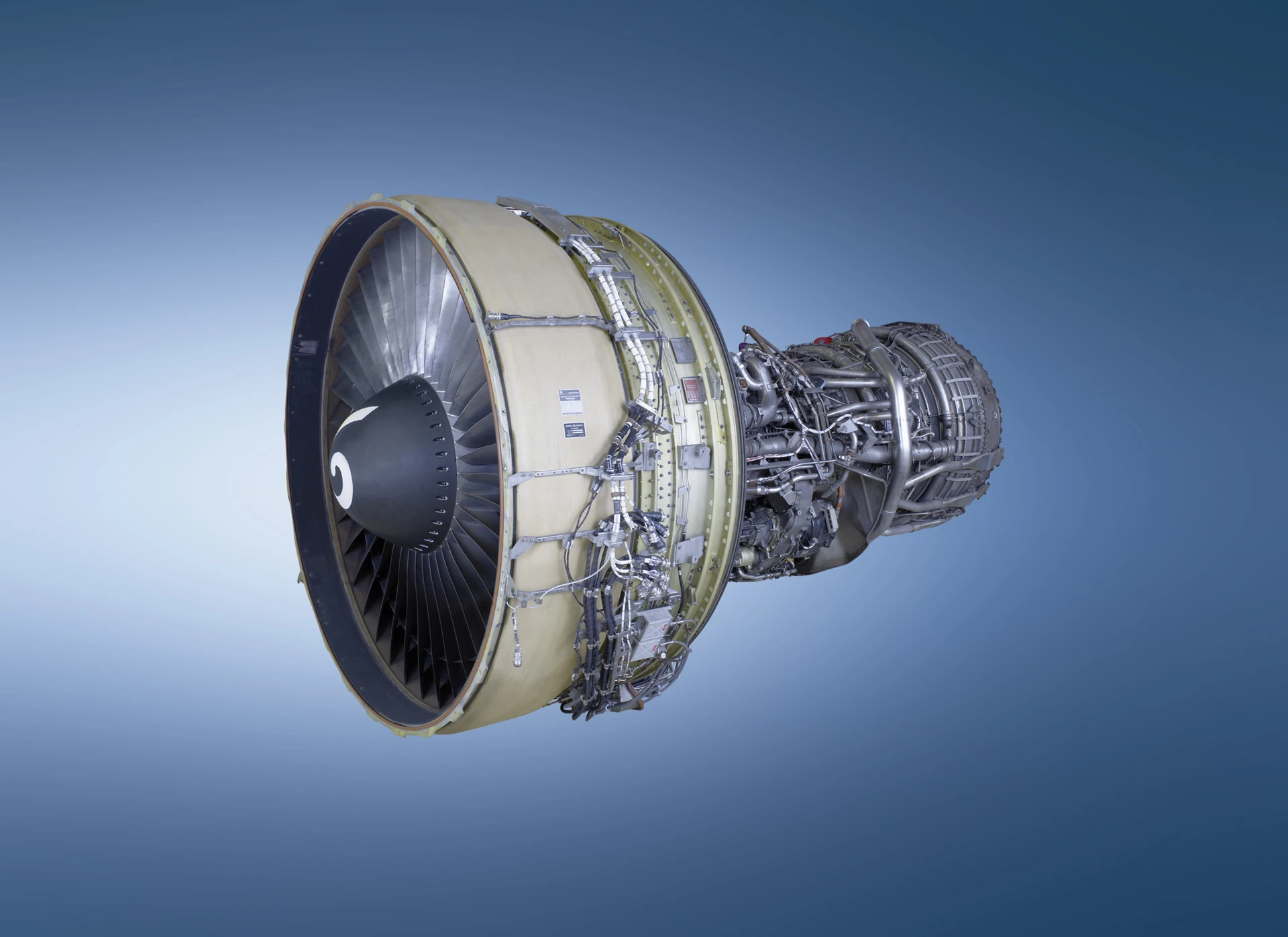

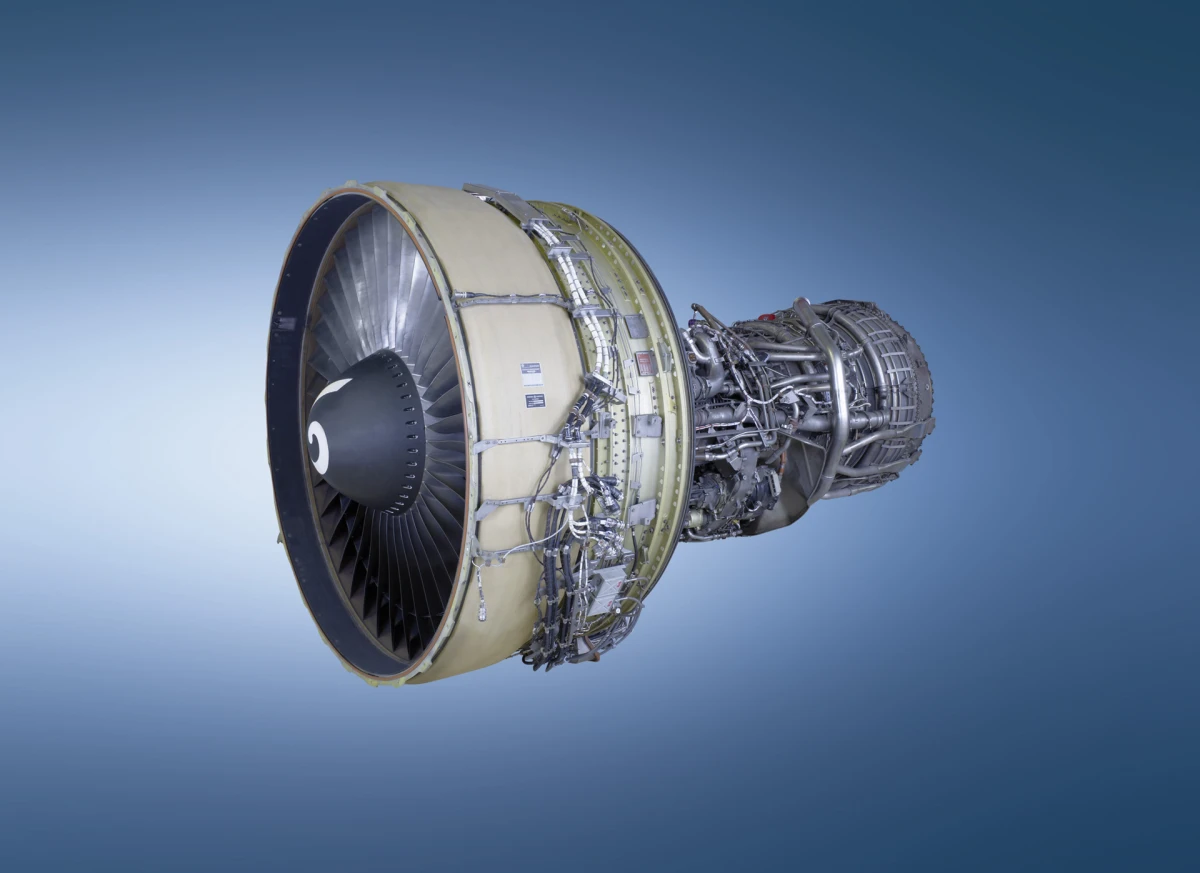

CF6-80C2: the widebody classic turns forty

Over 1.9 million flight hours: the CF6-80C2 is one of the world’s most successful engines—and its story is far from over.

author: Saša Lakić | mins reading time published on: 08.01.2026

author:

Saša Lakić

is the Berlin-based Media Relations Manager for the global MTU Maintenance network, and worked as a reporter before joining the logistics department at MTU Maintenance Canada in 2019. He enjoys learning about engines, collecting records, and the Oxford comma.

The CF6-80C2 has seen much over the course of its lifetime: the fall of the Berlin Wall, the ascendance of the Internet Age and the proliferation of smartphone technology. And since its entry into service in 1985, it has carried anything from last-minute holiday and birthday presents to the President of the United States of America on the Air Force One, and always reliably and safely.

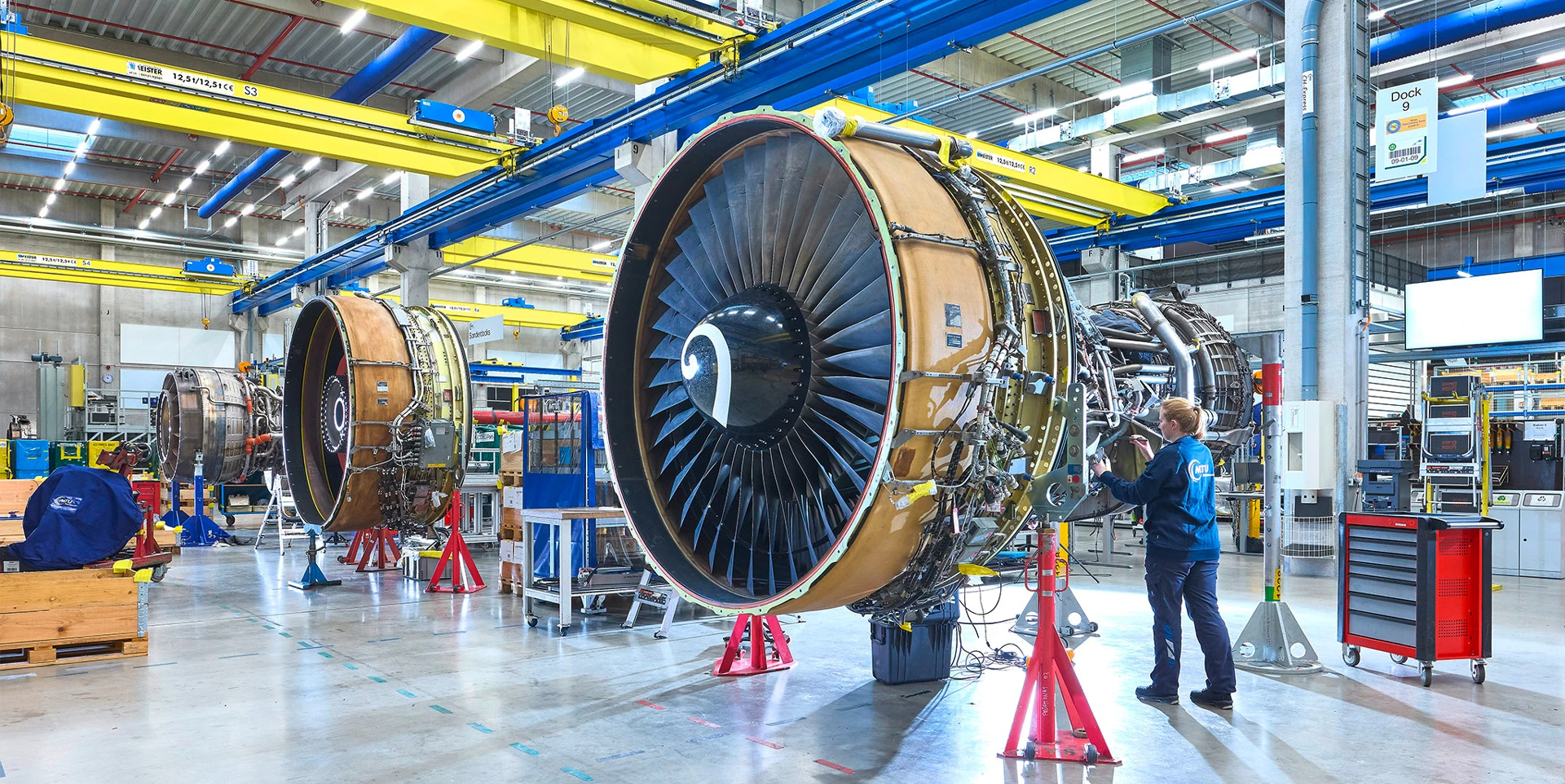

The now legendary CF6 engine family—and, indeed, best-selling widebody engine to date—laid the foundation of MTU Aero Engines’ widebody engine programs. Starting with the CF6-50 variant in 1971, it was the first commercial risk and revenue-sharing partnership between the company and GE Aerospace. As part of its 9.1-percent program share today, MTU manufactures blades, vanes and disks for the engine’s high-pressure turbine, as well as the forward outer seal and heat shield, at its Munich site. As the global “Dash-80” fleet kept growing and racking up millions of flight hours in the late 1980s and throughout the 1990s, the company also developed comprehensive maintenance, repair and overhaul (MRO) services for the aftermarket at its MTU Maintenance Hannover (since 1989) and MTU Maintenance Canada (since 2020) locations.

The recipe for success: simple, robust, and forgiving core architecture

Anjum Hashmi, Chief Powerplant Engineer for the CF6-80C2 program at MTU Maintenance Canada, has been working on CF6 engines since the early 1980s. For most of his career, he made the CF6-50 his area of expertise, first at Pakistan International Airlines and then at MTU as of 2000. He accredits the success of the CF6 family to its simple, robust and forgiving core architecture, which helps to reduce failures and extend maintenance intervals.

"That kept the CF6-engine family competitive for over half a century. We always had to evolve our know-how with new modifications and hardware updates."

Chief Powerplant Engineer

“Working on the same engine type for over 40 years was never boring,” says Hashmi, who takes pride in having been part in establishing the CF6-80C2 MRO program at the location south of Vancouver. “Every now and then, you would find something interesting that you had not seen before. GE also kept upgrading the hardware as the new technology was evolving. That kept the CF6-engine family competitive for over half a century. We always had to evolve our know-how with new modifications and hardware updates.”

As other MRO shops step away from the CF6-80C2, MTU Maintenance remains a primary service provider for it worldwide, particularly for freighter airlines, with tailor-made workscoping, dedicated teardowns, leasing and asset management, as well as on-site services. Since the original introduction of the CF6-80C2 program at the Hannover location in 1989, MTU has conducted well over 2,200 shop visits, and in recent years has been enjoying a 36-percent market share on global shop visit volume.

Fast Facts: CF6-80C2

- Global flight hours (2024): 1.97 million

- Current aircraft fleet size with CF6‑80C2 engines: 918.

- MTU has carried out well over 2,200 shop visits for this engine program

- The LM6000™ industrial gas turbine, a key program at MTU Maintenance Berlin-Brandenburg, is a direct derivative of the CF6‑80C2

- The military variant F138 is used in the U.S. Air Force’s C-5M Super Galaxy transport aircraft

Reliable workhorse for large payloads

The CF6-80C2 was developed in the early 1980s on the heels of the success of its CF6-6 and CF6-50 precursors during the preceding decades. Notably, the CF6-80C2 has a larger fan and a five-stage low-pressure turbine, which help the engine reach up to 63,500 pounds of thrust and make it an optimal workhorse for large payloads. Today, the engine model’s primary medium of operations is the Boeing 767F cargo aircraft, though it powers other freighter-conversion favorites, such as the Boeing 747 and Airbus A300. In fact, over 70 percent of the CF6-80C2 engine fleet propels freight, while only about one in five engines carry passengers. The rest is used for military purposes in the form of the F138 on the US Air Force’s C-5M Super Galaxy transporter, for example.

Around 120 airlines operate the engine model in their fleets, and passenger-to-freighter conversions saw a massive boom during the pandemic years. “The CF6 has by far the most flight hours by a widebody engine ever and the -80’s success is set to continue, thanks to the engine’s significant presence in the freighter market,” says Nicolas Emmrich, Market Analyst at MTU. “The CF6-80 was a true milestone for MTU: It positioned us as a global partner in the widebody segment, delivered decades of highly profitable aftermarket business and paved the way for our expertise in the widebody engine sector, including the new-generation GEnx and GE9X programs.”

By 2040, the global fleet powered by -80s will fall to about 450 aircraft from today’s 918, and MTU’s leading approach to engine MRO will only grow in importance for freight carriers and other operators looking to phase out their assets in the least costly way. Now, after 40 years of a remarkable, standard-setting tenure, the last CF6-80C2 will be delivered concurrently with the final Boeing 767F cargo aircraft in 2027. However, that does not mean it is the last we see or hear from it.