aviation

100 Years of Pratt & Whitney – MTU as a reliable partner

This year, Pratt & Whitney is celebrating its 100th anniversary. For many of those years, MTU has been at its side: the two companies signed their first license agreement back in 1928.

author: Eleonore Fähling | 4 mins reading time published on: 17.06.2025

author:

Eleonore Fähling

has been on the AEROREPORT editorial team since 2014 and in charge of the MTU employee magazine since 1999. As an aerospace journalist, she specializes in aviation history and market topics.

You may also be interested in following content

MTU history

MTU’s roots reach back to the dawn of aviation.

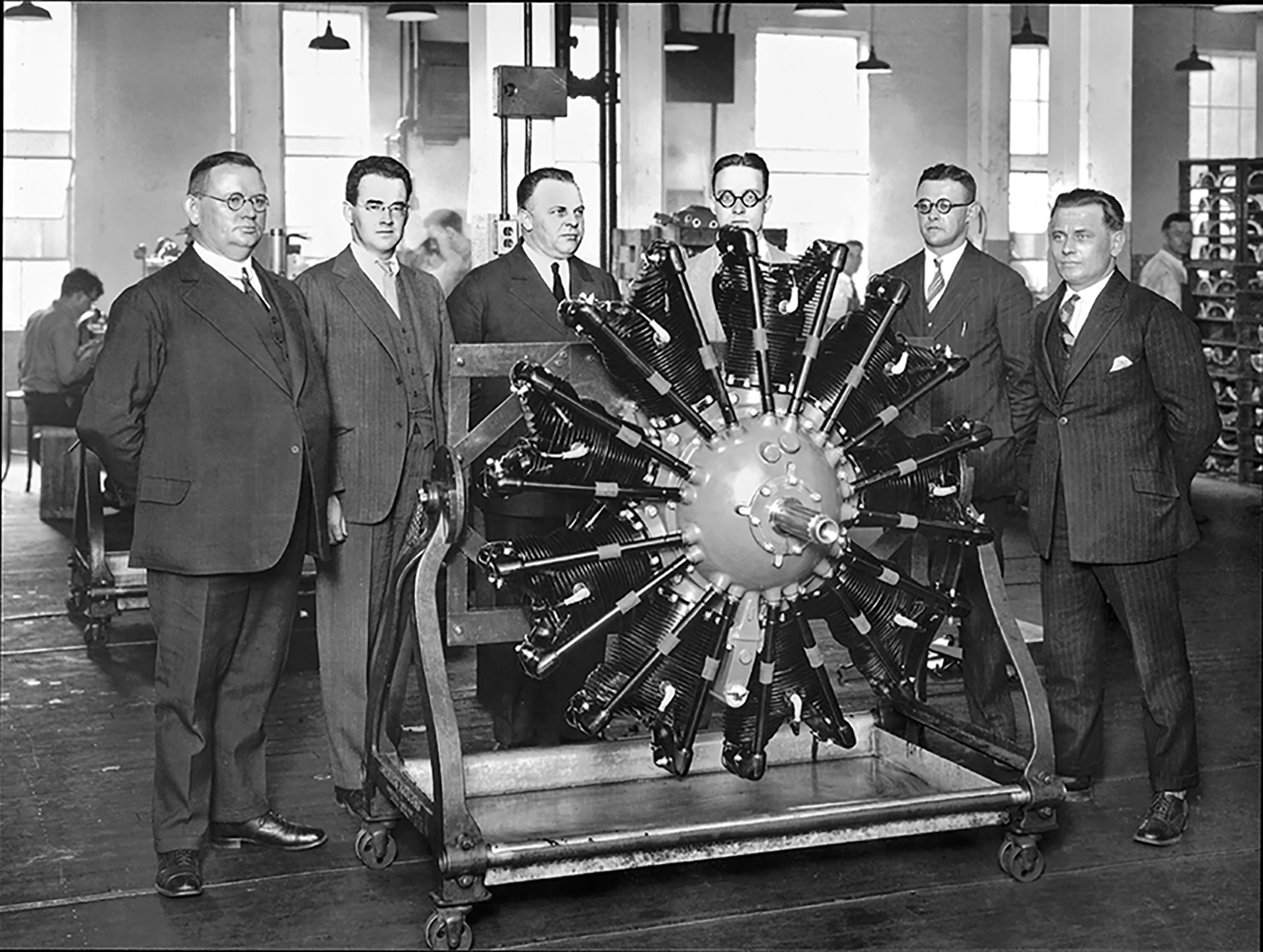

In 1927, when a German company wanted to do business with an American company, the managers didn’t just hop on a plane. The first nonstop transatlantic flight had only just been completed, and passenger flights on this route were still unthinkable. Negotiating a license agreement and having it signed by both parties meant multiple trips across the Atlantic by steamship, with a one-way trip taking around three weeks. In 1927, representatives from Pratt & Whitney in Hartford, Connecticut, and from Bayerische Motoren-Werke AG in Munich, Bavaria, had to make this trip several times. None other than Max Friz himself, the legendary chief designer at BMW, was instrumental in driving the negotiations forward.

MEMORANDUM of AGREEMENT made as of the 3rd day of January, 1928

In fact, there was a license agreement between the two companies—judging by the typeface, drawn up on an American typewriter—bearing four signatures and the BMW AG stamp in the Fraktur font, executed on January 3, 1928. This marked the beginning of the joint history of Pratt & Whitney and today’s MTU, the legal successor to BMW Flugmotorenbau GmbH, which was spun off in 1934. BMW wanted to build modern, air-cooled aircraft engines, so it acquired the European license from Pratt & Whitney to reproduce the Wasp and Hornet radial aircraft engines. These served as the basis for the BMW 132 engines that powered the famous Junkers Ju-52.

From exhaust casings to low-pressure turbines

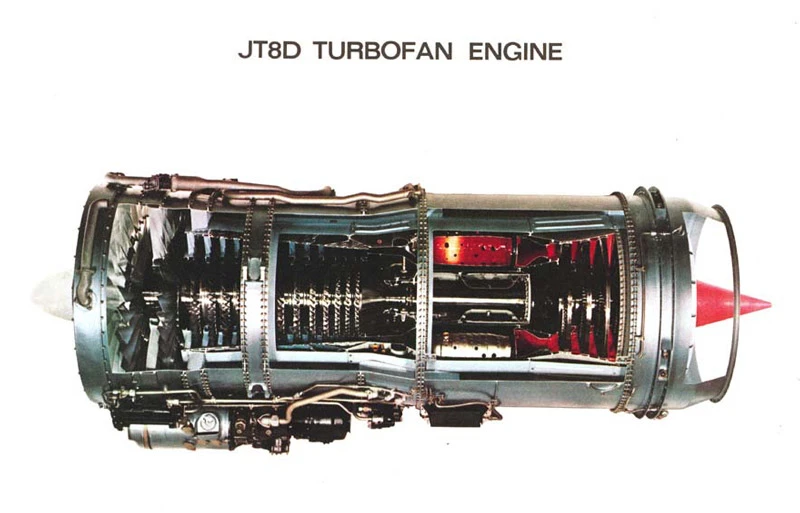

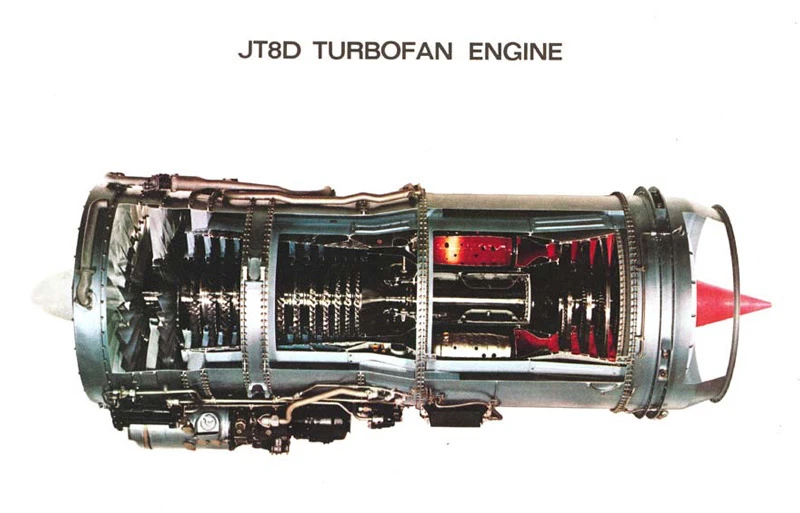

One world war and a few decades later, the collaboration began anew. In 1971, U.S. company Pratt & Whitney (P&W), the then world market leader, commissioned MTU to develop and build a noise-reducing exhaust casing for a thrust-enhanced version of its mainstay engine, the JT8D. MTU’s long-time Head of Development Ludwig Schweikl, who designed the housing with his team, reported that the company had already been in contact with P&W through the manufacturing department. The MTU engineers and their performance won P&W over, and the transatlantic cooperation proved its worth. In 1973, an agreement was reached regarding MTU’s participation in the JT8D successor program. That same year, MTU was awarded the contract to develop a new low-pressure turbine for the JT10D project. Under the name PW2000 and with an MTU share of 21.2 percent, it completed its first run on December 4, 1981. As a risk and revenue share partner, MTU was not only paid for work performed, but also shared in the profit as well as the risk.

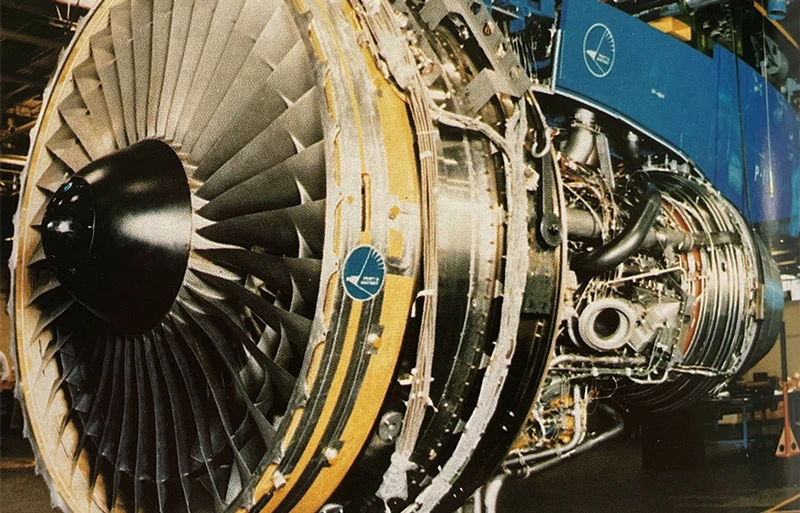

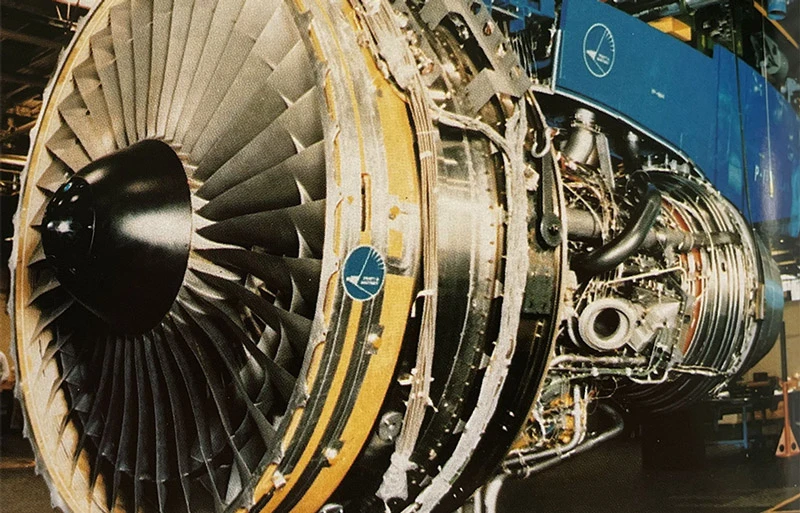

With the PW2000, MTU was responsible for the design of an entire module for the first time—and developed its expertise further. That’s because the technical innovation in the low-pressure turbine was its active gap control: the turbine case is cooled, which compensates for the differences in thermal expansion of the components and thus increases the efficiency of the module. While the idea came from Pratt & Whitney, MTU was responsible for its implementation. Today, this feature is standard in engine construction.

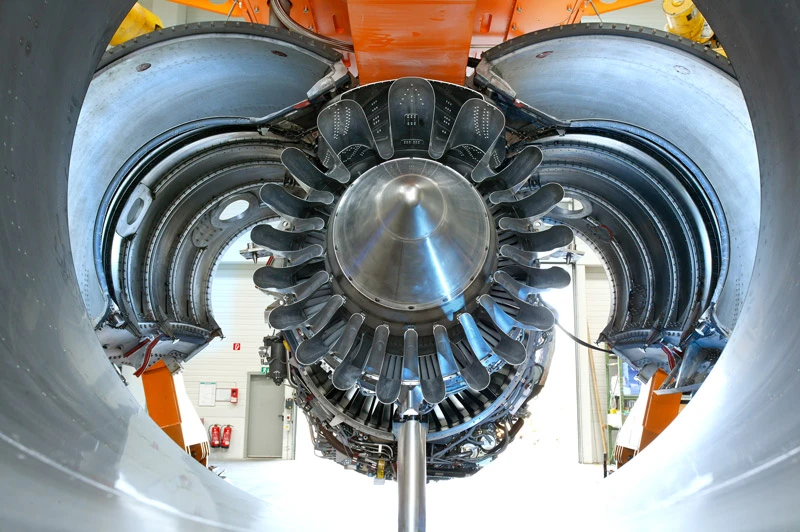

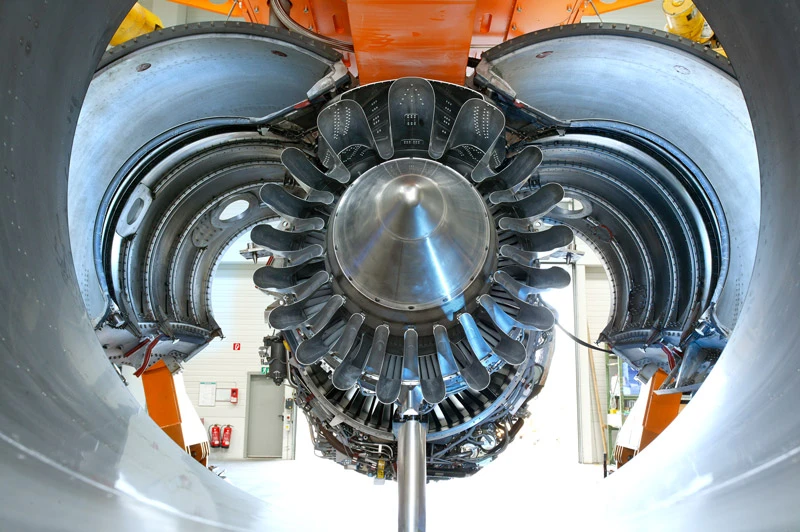

Network partners and a core engine

Consequently, MTU was again involved in developing the PW6000 in the 1990s, which was initially planned exclusively as an engine for the Airbus A318, the smallest member of the A320 family. Neither the aircraft nor the engine was ultimately a commercial success; production ended in 2013, flight operations in 2019. But for MTU, the program was truly groundbreaking: the HDV12, a compressor rig developed at MTU and used to test technical developments, fitted perfectly into the PW6000. The six-stage high-pressure compressor (HPC) was given preference over P&W’s own HPC, marking MTU’s successful entry into the commercial core engine market. The PW6000 also served as the basis for a geared turbofan demonstrator, which P&W and MTU started developing together in 2006. This in turn laid the foundation for the geared turbofan engine family, the development of which began in 2008.

Fly-by-Hour

In a fly-by-hour contract, the airline or lessor that purchases an engine doesn’t pay a fixed purchase price, but rather for hours flown. The less time the engine spends in the shop for overhaul, the more the engine manufacturer earns. Overhauls and repairs are carried out in the manufacturer’s own shops or in its network shops. MTU Maintenance is part of Pratt & Whitney’s MRO network for GTF engines.

“The PW6000 was to be the start of the first family concept with the planned PW8000-GTF, but that model was later discontinued,” explained the then technical program manager Dr. Günter Wilfert, speaking with the MTU employee magazine “contact” in 2012. The idea was taken up again with the GTFTM engine family and the PW800: the engines of the PurePower family, as it was called for a time, share a common core “from which we derive various applications, whether conventional or with a gearbox,” Wilfert said. Another first for the PW6000 was the new, joint paths taken in the aftermarket business: “MTU has been involved in the aftermarket business from the very beginning, particularly in long-term maintenance contracts (fly-by-hour), and has been actively engaged in the Pratt & Whitney MRO network,” said Robert Salminger, then (as now) a member of MTU’s aftermarket and customer support team. Last but not least, the PW6000 marked the first time that P&W entrusted MTU with important approval tests and the complete final assembly—this also proved successful and has been repeated for the GTF family.

How an initial collaboration evolved into a partnership of equals – shaped by the highly successful V2500 engine program and the Pratt & Whitney GTF™ engine family – is the focus of our next article.