aviation

MTU Aero Engines 90 years of engine excellence

MTU has been at the forefront of the engine industry for nine decades. The company has maintained this leading position thanks to its innovative strength and expertise—and the story is far from over.

author: Eleonore Fähling | mins reading time published on: 11.12.2024

author:

Eleonore Fähling

has been on the AEROREPORT editorial team since 2014 and in charge of the MTU employee magazine since 1999. As an aerospace journalist, she specializes in aviation history and market topics.

MTU Aero Engines looks back on a dynamic history marked by technical milestones. Since its beginnings as BMW Flugmotoren GmbH, the company has consistently pushed boundaries – with groundbreaking technologies like the low-pressure turbine and high-pressure compressor for the geared turbofan, as well as building a global maintenance network.

In the military sector, MTU has also become a trusted partner for cutting-edge propulsion technologies, shaping the next generation of engines for fighter jets and helicopters. With a clear vision of making emission-free flying a reality, the company combines decades of experience with state-of-the-art technology to shape the future of aviation.

The history of MTU shows: Where tradition meets innovation, progress is born.

90 Years and Beyond: MTU Aero Engines has been at the forefront of the engine industry for nine decades. The next chapter in its success story will be propulsion concepts that enable zero-emission aviation by 2050. The expertise and passion of its employees brought the mtu to this point and will continue to carry it into the future.

There from the outset

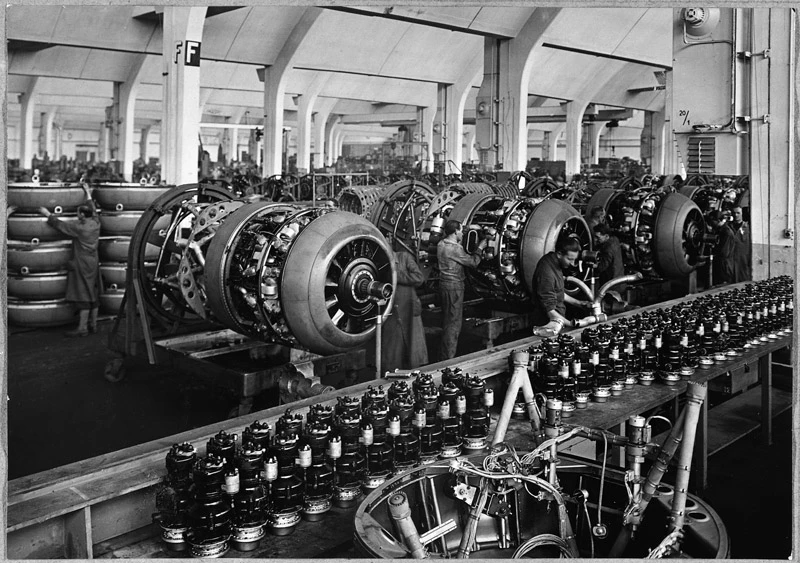

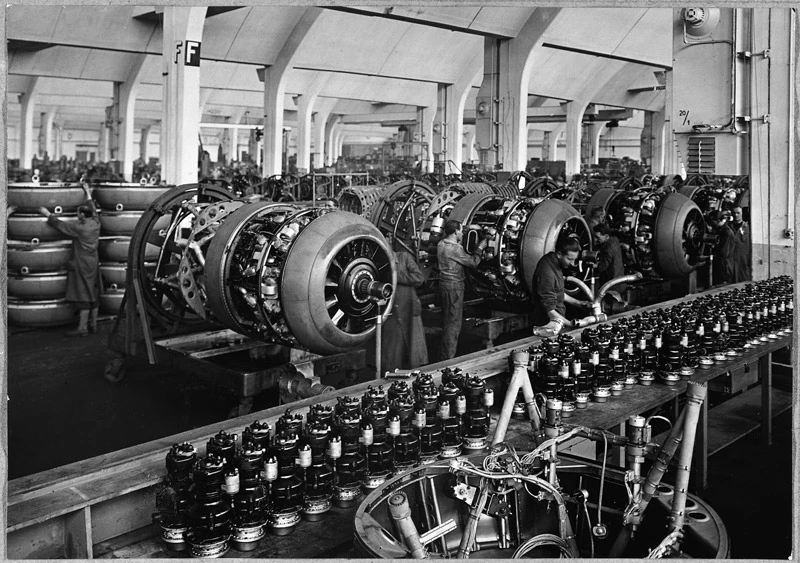

MTU Aero Engines AG has its origins in BMW Flugmotorenbau GmbH, which was founded in 1934 to bring together the aircraft engine activities of Bayerische Motoren Werke AG in Allach near Munich. BMW was already active in aircraft engine production during the First World War; indeed, the BMW logo can be interpreted as a stylized aircraft propeller. After the Treaty of Versailles prohibited aircraft engine production in Germany, BMW initially turned its attention to motorcycles and automobiles. It began to produce aircraft engines again in the second half of the 1920s.

In 1933, the Nazis geared the German economy toward arming for war and specifically promoted technical developments such as the jet engine. BMW Flugmotorenbau GmbH produced air-cooled aircraft engines with cylinders arranged into star shapes and developed the BMW 109-003 jet engine, which flew for the first time in 1941.

Restart and growth

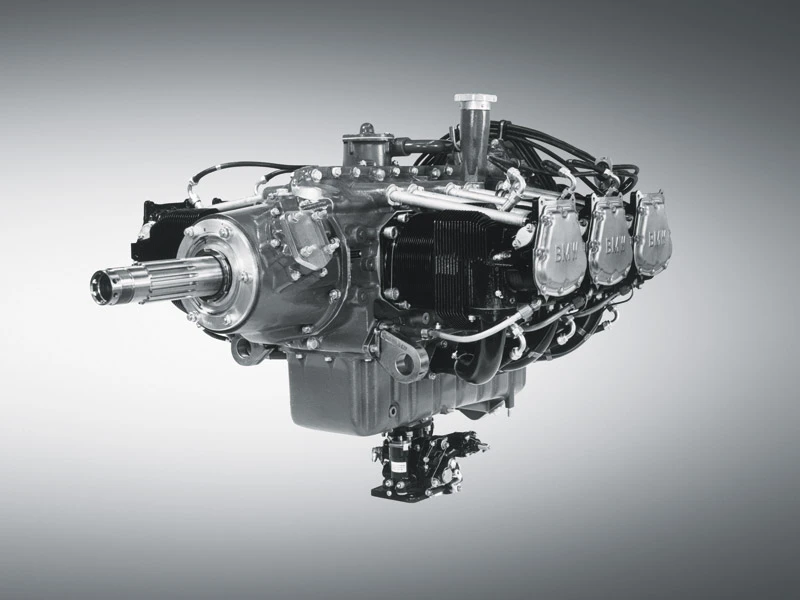

For ten years after the end of the Second World War, the U.S. Army used the premises of BMW Flugmotorenbau GmbH as an engine maintenance facility for army vehicles. In 1955, MAN bought the northern part of the factory premises in Munich-Allach. On the rest of the BMW site, the remaining employees set up the infrastructure they needed to recommence work on aircraft engines. In the 1950s, BMW was a successful exporter of cars and motorcycles, but the company also resumed aircraft engine production.

MTU goes global

For MTU customer proximity is key. She is globally present with her network of locations. MTU established its first North American subsidiary, MTU Maintenance Canada, in 1998. This was followed by Vericor Power Systems in Atlanta and Aero Engines Design (AED) in Connecticut; the latter was renamed MTU Aero Engines North America in 2002.

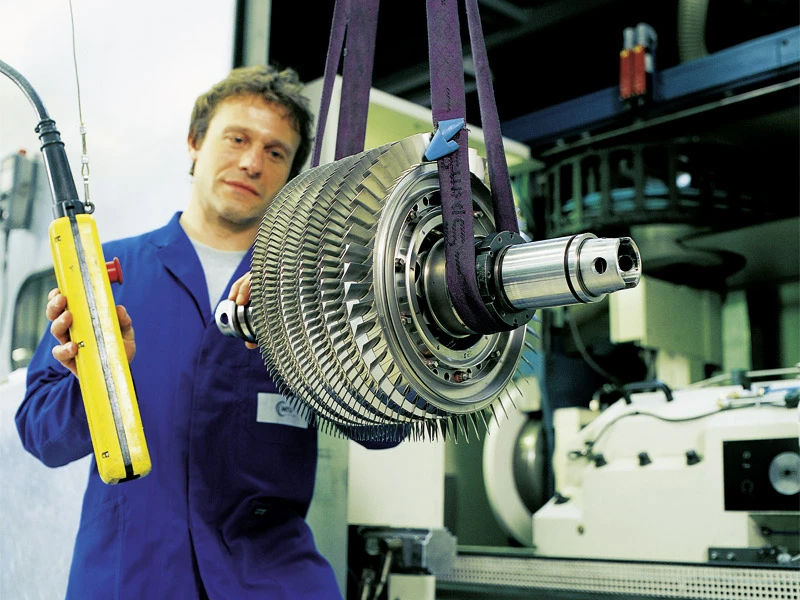

Engine components “made by MTU” are among the world’s best

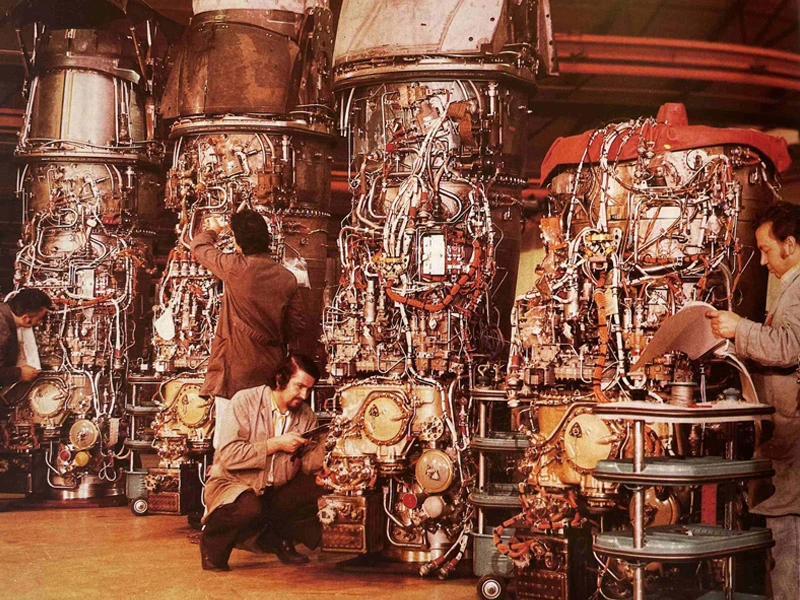

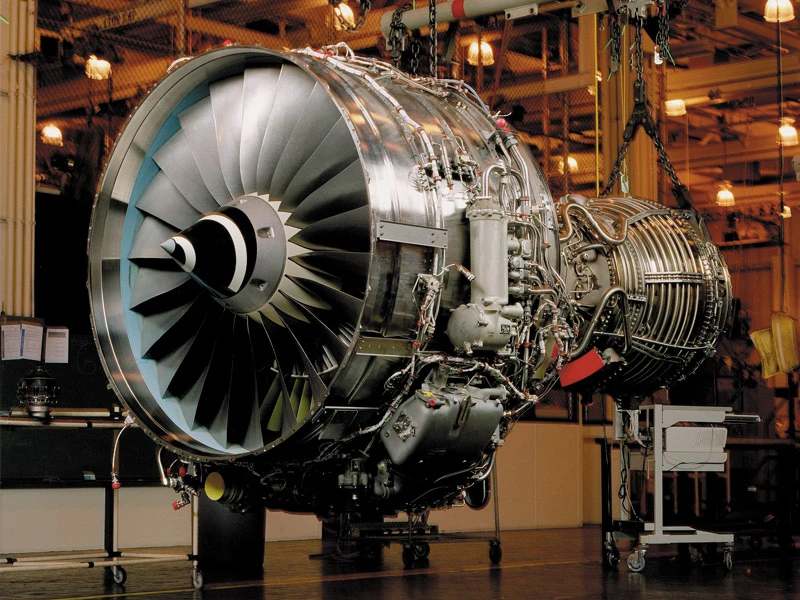

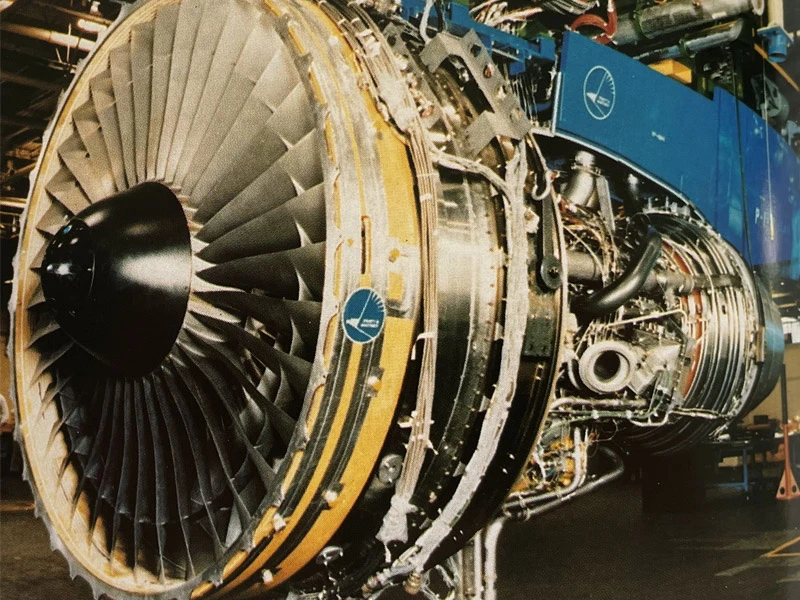

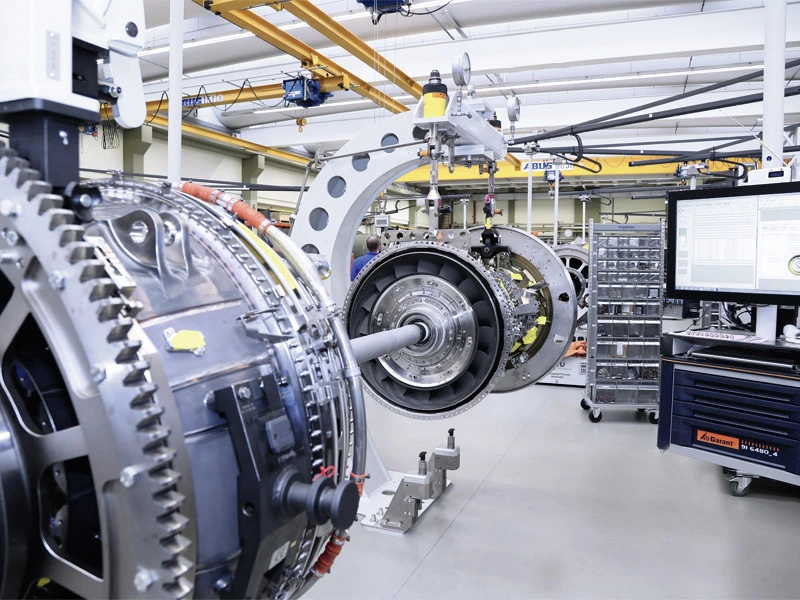

In the course of its 90-year history, MTU has developed numerous pioneering technologies—especially in the fields of low-pressure turbines and high-pressure compressors. Its development project for the Advanced Technology Fan Integrator (ATFI) at the beginning of the 2000s, for example, led to the Pratt & Whitney GTF™ engine family, which has been in scheduled flight operations since 2016.

The story is far from over

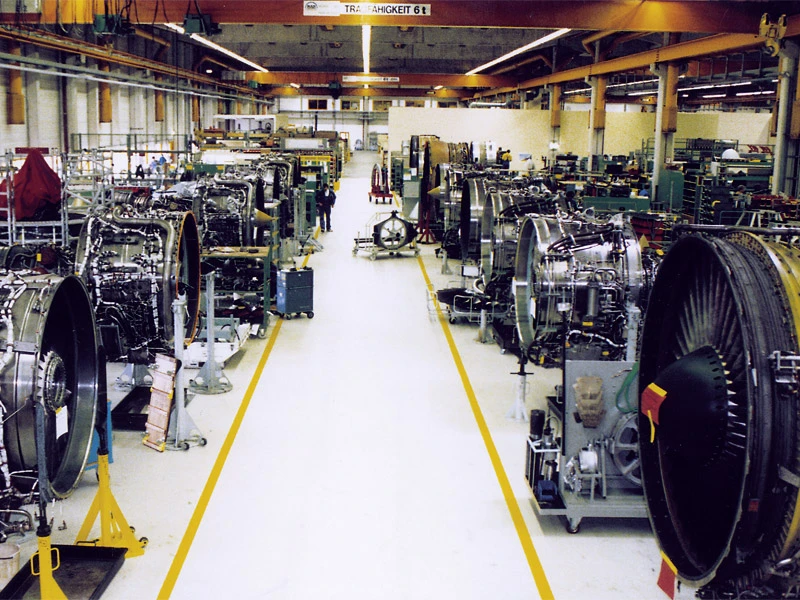

Today, one-third of the world’s commercial aircraft take to the skies with MTU technology on board. The engine specialist has developed into a global player with 18 locations worldwide and over 12,000 employees from 88 nations. And its story is far from over.

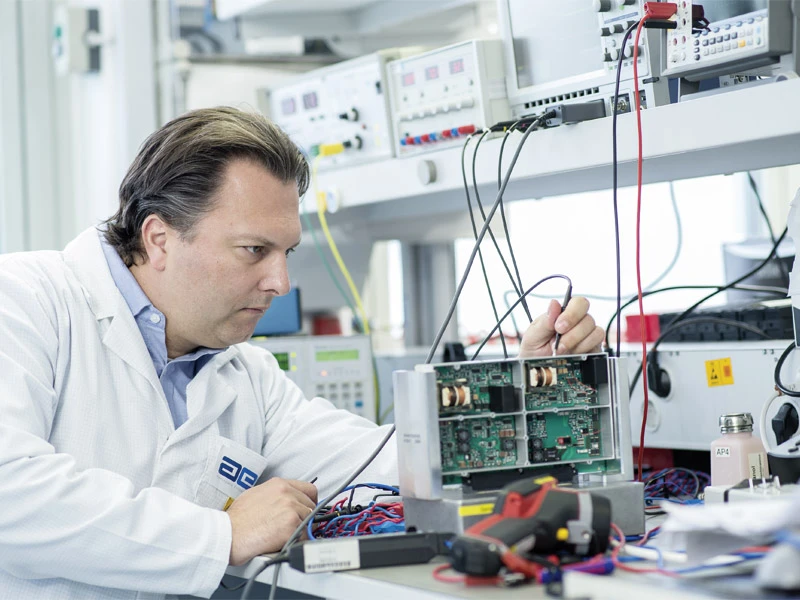

The demands placed on technologies today are greater than ever: aircraft and engines must become even cleaner, quieter and more efficient—the vision for the future is emissions-free flight. The guiding star is the Paris Agreement’s goal of limiting global warming to preferably 1.5 degrees Celsius by the end of the century. Getting there calls for innovative technologies and groundbreaking propulsion concepts. A key driver of innovation, MTU systematically positions itself at the forefront of this development. In its technology agenda, the company lays out potential solutions and concepts for sustainable commercial engines with the aim of meeting global climate goals. MTU’s experts are working on evolutionary and revolutionary technologies simultaneously. Key elements are enhancements of the gas turbine engine based on the geared turbofan as well as the Flying Fuel CellTM.

And MTU is also setting standards for the future in the military sector: the New Generation Fighter Engine (NGFE) powers the New Generation Fighter (NGF), the next-generation fighter jet that is the centerpiece of Europe’s Future Combat Air System (FCAS). Together with Safran Aircraft Engines and the Spanish engine and component manufacturer ITP Aero, MTU is developing, producing, and providing support for the system. MTU’s involvement in the NGF also sees the company continue its tradition of military compressors: for the NGFE, MTU is developing and manufacturing the entire compression system consisting of low-pressure compressor, inter-compressor duct, and high-pressure compressor. And there’s more: MTU is also involved in the propulsion system for the next generation of European military helicopters.