aviation

MTU in North America: Rapid ramp-up for LEAP and GEnx engines

MTU is on course for growth in North America: It’s expanding its on-site service center in Fort Worth, Texas, into a full-fledged maintenance facility for LEAP and GEnx engines — with complete disassembly, assembly, and testing capabilities.

author: Nicole Geffert | 4 mins reading time published on: 01.09.2025

author:

Nicole Geffert

has been working as a freelance journalist covering topics such as research and science, money and taxes, and education and careers since 1999.

Jakob Nagl, who works at MTU Maintenance Fort Worth in Texas, has a favorite movie: “Field of Dreams.” The 1989 film tells the story of a corn farmer in the U.S. state of Iowa who, after a flash inspiration, plows up his cornfield and turns it into a baseball field — complete with bleachers and floodlights. The result is a magical place that’s initially met with skepticism. But the voice of prophecy whispers to him: “If you build it, they will come.” And that’s how the story gets started.

Nagl, Head of Value Stream Management and Operations Support, appreciates the film’s message: that passion and the will to realize your own dreams can bring about profound changes. This thought occurred to him when he first entered the imposing facility into which MTU Maintenance Fort Worth had just moved in 2023. The on-site services (OSS) and industrial gas turbine businesses operating there occupied only a small part of the building’s 40,000 square meters of floor space. “There was a real spirit of optimism in the air,” Nagl remembers.

Now, two years later, every square meter is bustling with activity. That’s because MTU Maintenance Fort Worth is being expanded from an on-site service center to a full-fledged maintenance facility — with full disassembly, assembly, and testing capabilities for LEAP-1A/-1B and GEnx engines.

MTU Maintenance Fort Worth is being expanded from an on-site service center to a full-fledged maintenance facility—with full disassembly, assembly, and testing capabilities for LEAP-1A/-1B and GEnx engines.

Stepping boldly into the future

André Sinanian, Managing Director of MTU Maintenance Berlin-Brandenburg, was responsible for the OSS site. He remembers when discussions about the expansion began: “Dave Kircher, GEnx Product Line General Manager of GE Aerospace, and I spoke at the 2022 Paris Air Show about the need for MRO capabilities, especially for the new GE programs in the U.S., so we could offer our customers even better service.” The focus was on setting up a GEnx maintenance shop in North America. “It’s great to see how that idea has now become reality,” Sinanian says. MTU took a chance on the project and moved to a much larger facility in Forth Worth—even though its business wasn’t big enough at the time to cover the new building’s operating costs. “We believed in the market potential and in the sustainability of our partnerships, including our cooperation with CFM International. Around the same time, we entered into discussions with our colleagues at GE and Safran about introducing LEAP engines into our maintenance portfolio, and we ultimately won the highly coveted LEAP business. For the LEAP, too, the need for maintenance capacity was highest in North America. And that’s precisely what our new shop offers,” Sinanian says.

Gernot Sell, who was appointed Managing Director of MTU Maintenance in Fort Worth in February, shares Sinanian’s conviction: “Without this investment, MTU probably wouldn’t have been awarded the maintenance contract for the LEAP-1A/-1B and GEnx engines.” MTU is looking to significantly grow its North American maintenance business. And Fort Worth will play a central role in that growth as a full-fledged MRO shop. By 2050, MTU will have invested around 120 million U.S. dollars in modernizing and expanding the site, which is strategically located at Perot Field Fort Worth Alliance Airport. Dallas Fort Worth International Airport is less than 30 kilometers away.

MTU’s global teams are used to working against the clock. But the timeline in Fort Worth is even tighter than usual. The first LEAP-1B engine is scheduled to visit the shop on July 1, 2026, with the LEAP-1A to follow six months later—as agreed with the CFM International engine consortium. “The demand for capacity and maintenance services is high. After all, the LEAP is one of the world’s biggest engine programs,” Sell says. “That’s particularly true in North America, where Fort Worth will let MTU offer comprehensive services and customer proximity.”

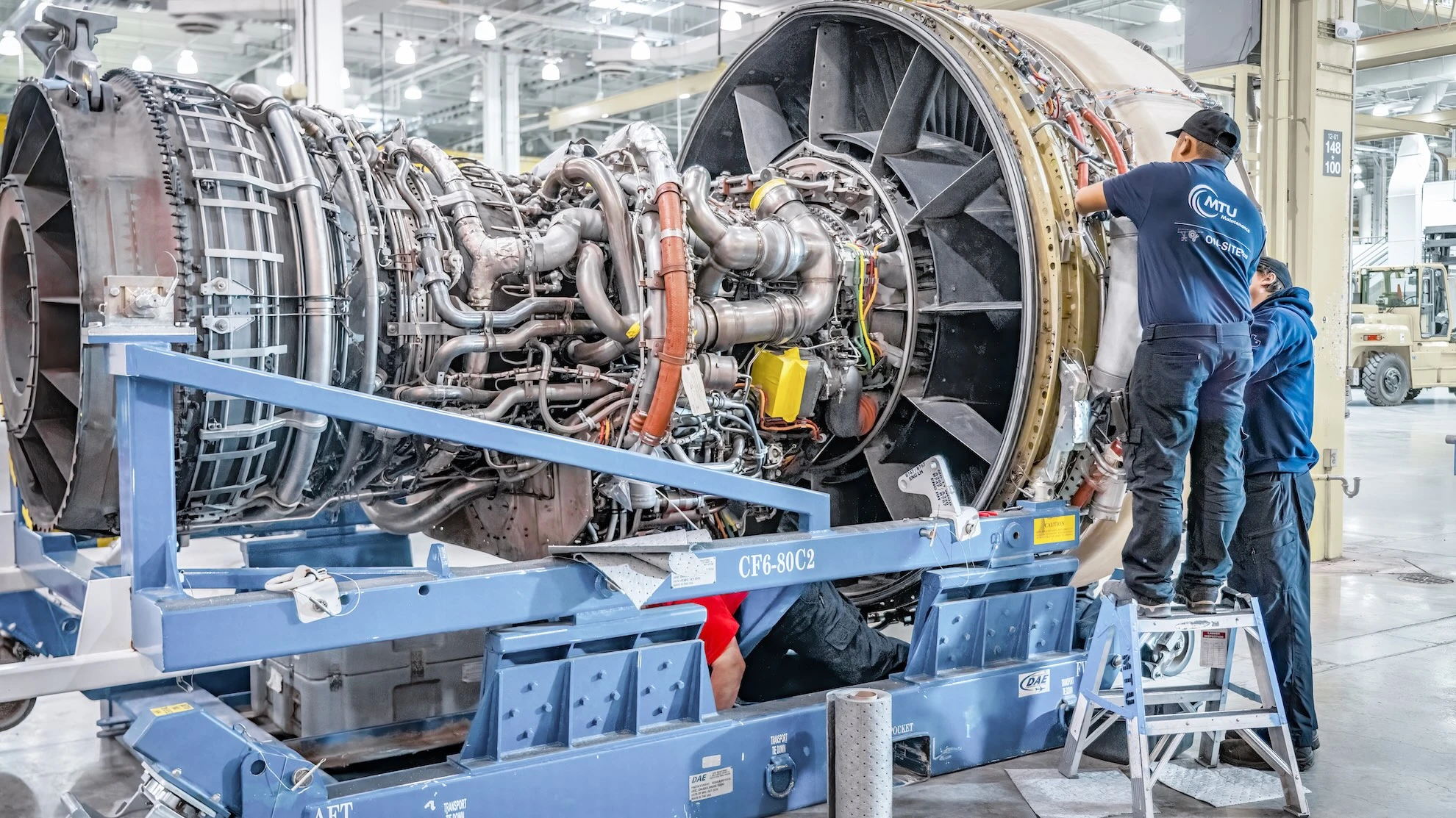

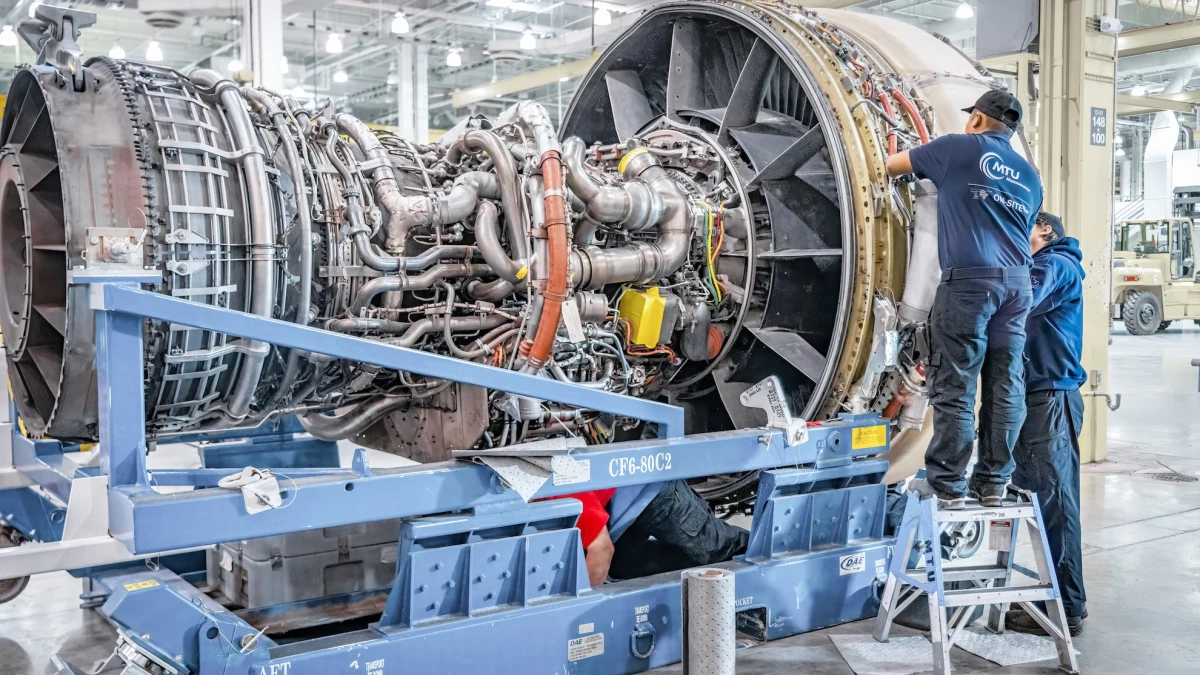

Working on-wing: MTU Maintenance's OSS assignments usually have to be carried out quickly. Like here with the GE90, the world's largest engine, which the experts have made ready for take-off again.

Business as usual during expansion

Day-to-day business will of course continue, and MTU customers will continue to receive reliable support during the expansion. “A full 60 percent of operations take place here in the shop. Our teams complete 40 percent on-site, meaning at the customer’s premises,” Nagl reports.

"On-site services will remain an integral part of our business even after the expansion."

MTU Maintenance Fort Worth

Plans for the expansion incorporated experience from all MTU’s sites. “The expertise we can access by teaming up with the MTU network is what made this major project possible in the first place,” Sell says. A decision that has proven successful at other MTU sites is to keep the production lines for narrowbody and widebody engines physically separate. Equipment with special foundations will be placed at the edge of the facility, which gives MTU flexibility if the shop needs to expand at a later point.

Overhead cranes will be used wherever possible to move things around the shop. This keeps routes clear and lets MTU largely dispense with forklifts and pallets. The fixed overhaul system is an innovative disassembly and assembly system that was successfully developed in-house by a team of MTU experts in Munich. Numerous systems, such as grinding systems and balancing shafts, have already been ordered; the chemical cleaning system has been specified and will be ordered soon.

Upgrading the test cell

“We’re working diligently to complete the training center so that we can start training on the engines in October,” says Kevin Robinson, Director Human Resources. Over the next ten years, the Fort Worth site will grow considerably. “We currently employ 128 people. We estimate that the site will create around 1,200 highly qualified jobs, along with up to 2,000 indirect jobs in the areas of services, logistics, and infrastructure,” Robinson explains. This means that, in addition to expanding the shop and integrating new IT systems, MTU also needs to recruit more specialists—especially from the nearby area, which is considered an aviation hotspot.

At the same time, a cross-site team of MTU experts is retrofitting the test cell. To date, the test stand for engines up to 100,000 pounds was correlated to the CFM56-7B engine. The building and cranes will remain as they are, but the electronics will be completely replaced to make sure that the test cell can reliably map the LEAP’s higher data capture rate in the future.

You may also be interested in following content

MTU Maintenance Fort Worth

Located at the Fort Worth Alliance Airport near Dallas, Texas, the site is MTU Maintenance’s main hub for ON-SITEPlus services in North America and will be developed from an on-site service center to a full disassembly, assembly and test facility.

With the expertise of the MTU network

The network enablement team, headed by Jörg Vogl from MTU Maintenance Hannover, is also in action in Fort Worth. This interdisciplinary team supports the sites in the MTU network with new construction, remodeling, and ramp-up projects—offering them expertise, best practices, and close collaboration on-site. The team’s work covers all important topics, including layout and material planning, engineering, production planning, as well as control, quality, and IT.

“We go to the MTU shops specifically to work together with the on-site teams to resolve these challenges,” Vogl says. Another key issue is the development and promotion of standards for MTU sites worldwide. “The aim is to bring together the best practices that exist in the MTU network and improve on them, always with the aim of becoming even more efficient and powerful as a network—for the benefit of MTU customers.”

All this effort will turn MTU in Fort Worth into a real best-practice shop. “This pooled expertise from across the MTU network will be an enormous help to us in getting set up quickly and efficiently,” Sell says. Additional support will come in the form of experts who transfer to Fort Worth from MTU sites around the world—all of them specialists in their field.

Premier MRO service provider

One of them is Tobias Wensky-Haferkamp from MTU Maintenance Hannover. This summer, he moved to Fort Worth to be the program manager and contribute his experience in the introduction of engine programs. Wensky-Haferkamp appreciates the dynamism of the up-and-coming MTU site in Texas.

“We’re confident that the ambitious expansion will succeed within a year—not least because the MTU network already has LEAP expertise,” he explains. LEAP engines already make their way to MTU’s Zhuhai site in China for repairs, and as of this summer. The Fort Worth site now makes MTU the sixth exclusive premier MRO service provider in the world for LEAP engines.

For MTU, that means the company is expanding its global maintenance offering for this engine program and extending its cooperation with GE. As an authorized maintenance organization, MTU Maintenance Fort Worth will also provide comprehensive services for the GEnx engine starting in 2030. This is based on a GE Aerospace Branded Services Agreement.

“In recent years, we’ve successfully introduced engines at MTU sites worldwide and benefited from our strong network,” Wensky-Haferkamp says. “We’re convinced that we’ll make a success of this and that we’ll deliver the performance our partners and customers expect from us.”