aviation

MTU Maintenance on course for further success

Foundation stone laid, portfolios broadened, site expanded: 2021 has been quite a year at MTU Maintenance. An overview of the highlights.

author: Victoria Nicholls | 5 mins reading time published on: 01.12.2021

author:

Victoria Nicholls

is an international communications expert. At MTU, she specializes in engine programs and market trends.

Over the past few years, MTU Aero Engines has remained committed to its network expansion plans and progressed with facility expansions, program and capability introductions as well as pursuing numerous operational, digitalization and efficiency improvement initiatives. Despite the COVID-19 crisis, MTU Maintenance is therefore prepared for the maintenance, repair and overhaul (MRO) ramp-up expected in 2022/23.

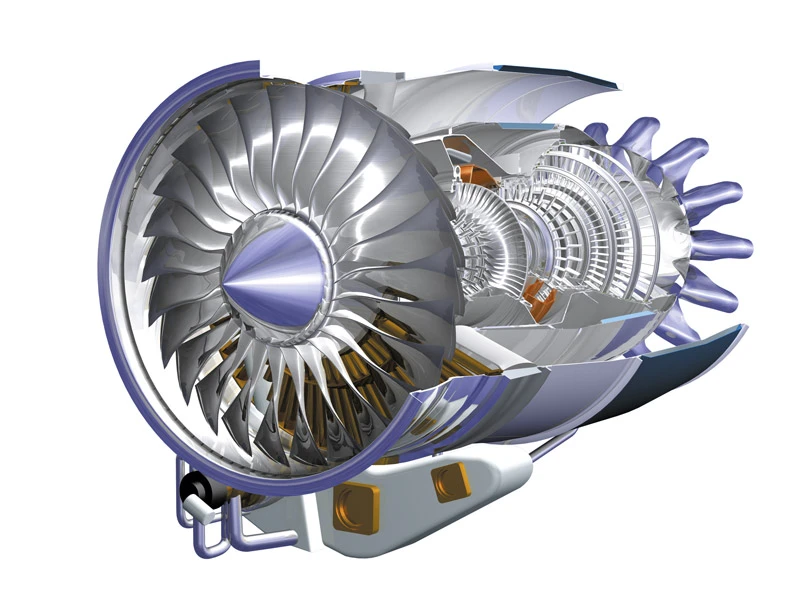

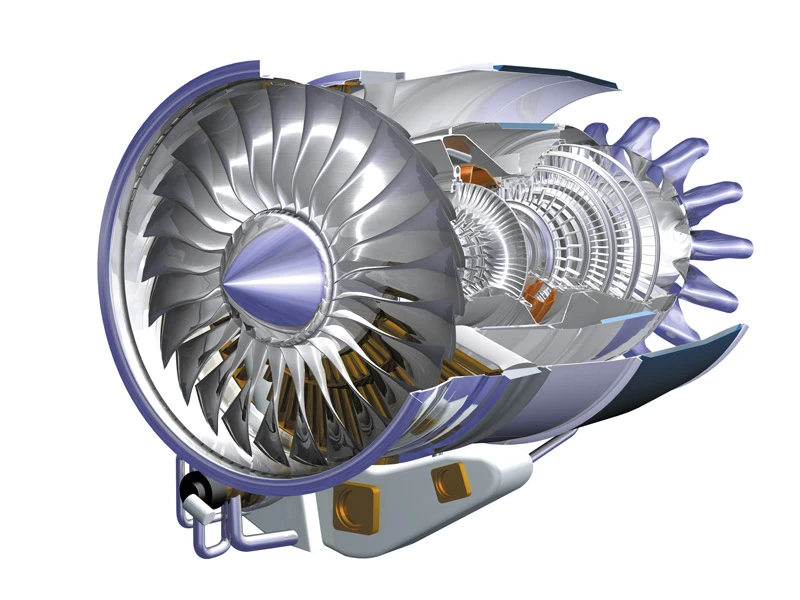

Domestic and regional air traffic in particular is showing signs of recovery, resulting in narrow-body engines tending to be reactivated first. MTU Maintenance is well-positioned to support these engines, as it now has capabilities for CFM56 and V2500 engines at three facilities worldwide. Furthermore, airlines have turned to younger engine types as they have moved their fleets out of storage. Here too, MTU Maintenance is ready to support. Three MTU facilities have capabilities for full engine disassembly, assembly and test for the successful PW1100G-JM engine. The LEAP family was also introduced in 2019 to MTU Maintenance Zhuhai and the team in the Pearl Delta region of China has been working hard to increase capabilities, in particular for its on-site team with for instance borescope inspections.

Furthermore, cargo operations even experienced a real boom throughout the crisis and MTU Maintenance has seen great demand for services on engines such as PW2000 and CF6-80C2. MTU Maintenance should return to pre-Covid levels by 2022/23 earlier than the market – thanks to its product mix and ability to offer alternatives, such as used serviceable material (USM).

This year in particular, MTU Maintenance had a number of milestones to celebrate around its sites. Groundbreakings, portfolio additions, facility expansions – to name just a few.

MTU Maintenance Hannover

9,000 shop visits reached

In July 2021, MTU Maintenance Hannover celebrated delivery of its 9,000th engine, a CFM56-7B for the Saudi Aramco fleet. MTU Maintenance has had the CFM56 family in its portfolio since 2000. As number one among independent CFM56 service providers worldwide, it has maintained well over 2,000 engines from this family over the past twenty years, holding a market share of over 10 percent.

MTU Maintenance Berlin-Brandenburg

A 30-year success story

There were several reasons to celebrate at Ludwigsfelde in 2021: MTU Maintenance Berlin-Brandenburg has reached the grand old age of 30—and it has looked after over 400 customers in the past five years alone. It possesses the most varied product portfolio of the entire MTU Maintenance network. And it added a new engine type to its portfolio this year, with the arrival of the first CFM56-7B in July.

P&WC Customer Service Centre Europe

MRO for PW307

Pratt & Whitney Canada Customer Service Centre Europe (CSC for short), a 50:50 joint venture between MTU Maintenance Berlin-Brandenburg and Pratt & Whitney Canada (P&WC), welcomed a new member to its engine portfolio in September: the PW307. MTU Aero Engines has manufactured PW300 engine parts since 1985. The CSC manages the service requests for these engines.

EME Aero

New GTF family member on board

In August, the first PW1500G engine was commissioned at the EME Aero shop. Its launch marks an important milestone in the short history of the joint venture between MTU and Lufthansa Technik. EME Aero is ideally prepared to welcome the new GTF family member. An assembly system designed especially for the location enables it to overhaul every engine type in the GTF family.

MTU Maintenance Zhuhai

New arrival: PW1100G-JM

MTU Maintenance Zhuhai had two highlights to announce in September 2021: The joint venture between MTU and China Southern Airlines Company Limited broke ground for the construction of a new site and welcomed the first PW1100G-JM in the shop. This makes MTU Maintenance Zhuhai the third MTU location to possess full assembly, disassembly and test capabilities for the engine type.

MTU Maintenance Canada

New home

With the move from Richmond to Boundary Bay in Delta, British Columbia, and the successful restructuring of a former helicopter maintenance company that went along with it, from now on MTU Maintenance Canada will have around 60 percent more space available. Over the past two years, MTU Maintenance Canada has added the successful V2500 and CF6-80C2 engine types to its portfolio.

MTU Maintenance Serbia

Foundation stone

On July 5, 2021, the groundbreaking ceremony took place at Nova Pazova for MTU Maintenance Serbia. At the new site near Belgrade, the wholly owned subsidiary of MTU will exclusively look after the repair of commercial engine parts. MTU is planning to commence operations at the end of 2022, and the training of skilled personnel has already begun.

Airfoil Services Sdn. Bhd.

Site expansion

In April 2021, Airfoil Services Sdn. Bhd., a joint venture between MTU Aero Engines and Lufthansa Technik completed its 5,200 square meter expansion, taking its yearly repair capacity from 650,000 to 900,000 parts. The facility near Kuala Lumpur in Malaysia is specialized in airfoil repairs for low-pressure turbines and high-pressure compressors, in particular for CF34, CF6, CFM56 and V2500 engines.

MTU Maintenance Dallas

More space for customer needs

In June 2021, MTU Maintenance announced the launch of its new ON-SITEPlus product family, which expands its portfolio of customized service solutions. The largest ON-SITEPlus location is MTU Maintenance Dallas. Just recently, MTU Maintenance Dallas expanded its available dock space by 3,700 square meters. Now it is able to accommodate engines for short- and long-term stays according to customer needs.

MTU Maintenance do Brasil

FAA approval to deliver more thrust

As of last year, MTU’s Brazilian location, which in the past had specialized in the maintenance of industrial gas turbines, is now also looking after aircraft engines—for CF34, CF6, CFM56, GE90 and V2500 types, do Brasil has already received ANAC and EASA certification and has carried out initial on-site activities on engines. FAA approval is due to follow at the end of this year.

MTU Maintenance Lease Services

Engine leasing gains momentum

Throughout the COVID-19 pandemic and resulting crisis, lessors have become even more involved in asset management. Their technical teams are now becoming busier with the return to service of the parked fleet, which is reflected at MTU Maintenance currently through increased demand for on-site support and technical asset management services.