aviation

MTU Maintenance: Training Programs Worldwide

MTU Maintenance offers comprehensive training programs worldwide that are specifically designed to prepare prospective engine specialists for a career in the aviation industry. Hands-on training and innovative methods ensure a successful start.

author: Thorsten Rienth | 8 mins reading time published on: 13.06.2024

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

MTU Maintenance qualifies new specialists at its locations worldwide in creative and well-thought-out ways: In Hannover, six-week compact DAT training courses offer an attractive entry-level opportunity. In Vancouver (Canada) and Nova Pazova near Belgrade (Serbia), the company cooperates with local educational institutions as part of unique programs. At EME Aero in Jasionka, Poland, it uses unusual teaching methods to impart knowledge.

MTU Maintenance: The global market leader in customized service solutions for aero engines works with passion and reliability to make flying safe and efficient.

Find out how MTU Maintenance implements comprehensive training programs worldwide:

“Word has gotten around in the region that the program is an attractive one.”

Technical Trainer at MTU Maintenance Hannover

Hannover, Germany

When Steffen Schreiber walks around the MTU Maintenance Hannover site, he sees many familiar faces. It’s not just because as a technical trainer, he sooner or later has to deal with almost everyone who maintains engines there. No, it’s more because for people who changed careers to work at Langenhagen, his was often one of the first faces they encountered.

Schreiber is one of the inventors and teachers of the compact DAT (disassembly, assembly, and testing) training courses at MTU Maintenance Hannover.

“It’s no secret that our industry is increasingly struggling to find skilled workers. Why not approach people who’ve already completed training in other metalworking professions and recruit them for MTU Maintenance Hannover?” However, the DAT concept is not a large-scale program for retraining people to become aircraft maintenance engineers. “It’s more a kind of MTU-specific training that acts as a gateway for us. It ultimately authorizes, say, a car mechanic to work on aircraft engines according to our internal specifications”, says Schreiber.

The six-week compact DAT training courses include a theoretical part with English, basic knowledge, and an introduction to engines, audits, and IT programs. It also has a practical section that focuses on real-life scenarios such as working on fan casings, high-pressure compressors, and low- and high-pressure turbine modules. From practice for practice, that’s the motto.

“Word has gotten around in the region that the program is an attractive one,” Schreiber says. “We get a large number of applicants, and the ones we admit are highly motivated.” One reason is because DAT is about much more than getting a taste of MTU for six weeks. “We want to prepare these new colleagues for the next step, which is actually much more important: on-the-job training in the individual MRO areas, such as module assembly.”

This on-the-job training lasts up to a year, depending on previous qualifications and skills. The final hurdle participants have to pass is the Level 2 test. “This is based on an internal MTU qualification that allows our colleagues to work on our engines extensively,” Schreiber explains. Since DAT was launched, several hundred new colleagues have joined via this route at the MTU Maintenance Hannover site alone.

Word has gotten around about this as well, only this time within MTU. Numerous other MRO locations in the MTU network have since adopted the DAT training concept and adjusted it to fit their requirements.

“It's not automatic that graduates of the program will go on to traditional employment. But that is clearly our goal.”

Trainer at MTU Maintenance Canada

Delta, Canada

The group of trainees could not be more diverse: some are only in their early 20s, others are already over 40. For some, handling tools is familiar territory, while others may be holding a wrench in their hands for the first time in their lives. While some participants have never had the opportunity to look at an engine up close, others already have a basic knowledge of its construction.

However, this diversity in the participants' prior knowledge and experience is not an obstacle. On the contrary: MTU Maintenance Canada's training concept is specifically designed to enable career changers to make a successful start at MTU Maintenance. Because all trainees have in common: They want to maintain engines in the future.

Brayden Eagles is one of them and actually studied biology. "The aviation industry is a completely new challenge for me. I find it incredibly exciting.” He spends the first 26 weeks of his training at the British Columbia Institute of Technology (BCIT), which is comparable to a vocational school from a German perspective, where he acquires theoretical knowledge. This theoretical phase forms the basis for the sub-sequent 20 weeks of intensive practical experience in MTU's MRO shop, in Delta, British Columbia.

“Hands-on” is the motto there. “Above all, they learn on original parts that are no longer 'flyable' for a variety of reasons,” explains Matthias Voss, trainer at MTU Maintenance Canada. "This gives them a very quick idea of the tasks that the parts perform in the engine.” The basics of materials science, mechanics, and trouble-shooting procedures are also taught.

“We’ve set up a kind of company within the company for the program,” says Voss. “It's a separate area, but one in which students work with MTU tools, processes, IT, and documentation from day one.” Each class that goes through the training program—the only one of its kind in Canada—consists of 12 students. Three classes start at different times throughout the year.

The genuine “MTU flavor” that Voss can attest to in the learning and working area is deliberate. “Graduates of the program don’t automatically get a regular job with us, but that’s clearly our goal.” Brayden Eagles would also like to make the leap into the company: “I just want to expand my knowledge every day and get to know all facets of the job of an engine mechanic so that I can make a valuable contribution to MTU later on.”

“Together with Serbian vocational schools and academies, we’re currently setting up a dual-track training system based on the German model.”

Support Team, MTU Maintenance Serbia

Nova Pazova, Serbia

When the decision was made in summer 2019 to build a new MTU repair site in Nova Pazova near Belgrade, the designated project lead for trainings and qualifications immediately got to work. “Serbia did have some maintenance companies in the metalworking sector,” recalls Hans Triebenbacher from the Support Team “but even though the country has a long history of aviation, the market needed some support. We had to come up with something, especially for the start of operations.”

Developing a training center at MTU Maintenance Serbia proved to be a challenging but rewarding journey. The first step was to initially train and qualify people. “Many colleagues from MTU Maintenance Serbia received their on-the-job training in Germany according to a plan tailored to our needs. By acquiring skills and competencies, they were able to bring the knowledge back to Serbia and share it with newcomers, now as trainers and instructors,” Triebenbacher says.

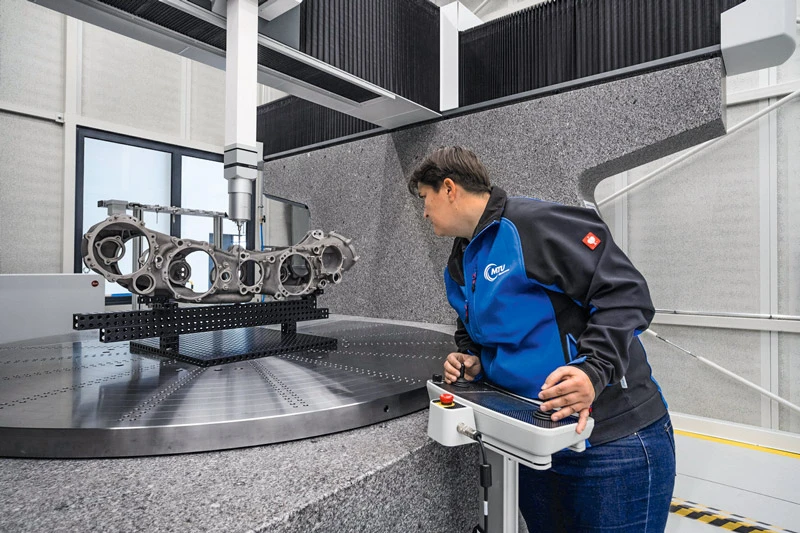

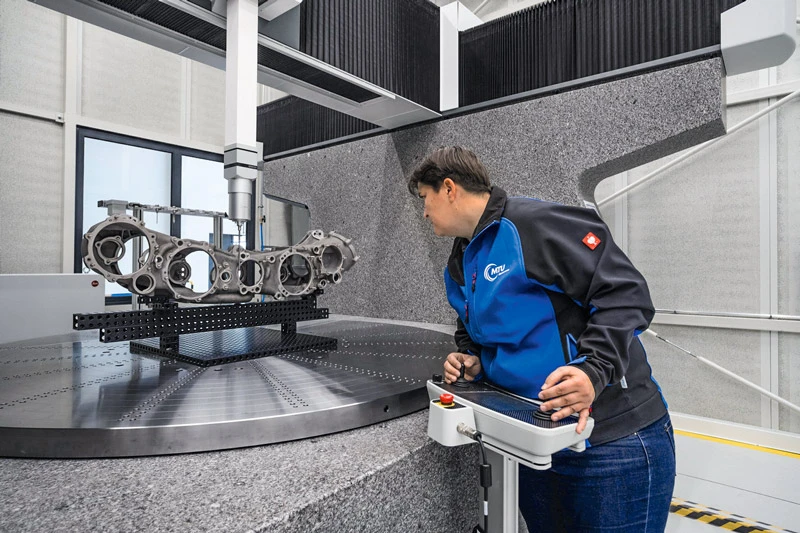

Jasminka Marković was one of the first to join MTU Aero Engines in Munich and MTU Maintenance Berlin-Brandenburg in Ludwigsfelde in this way as a trainee—and right in the middle of the pandemic. It’s no coincidence that she was one of those selected. “I was already quite familiar with coordinate-measuring machines, or CMMs, from my previous job,” she explains. “But aviation applications and the measurement software used at MTU were new to me.”

Ten months later, back in her home country, Marković became a trainer and began to pass on what she had learned. One of her students was Jovana Bosiljković. “Although Jasminka is my trainer and supervisor, we work together as equals,” Bosiljković says. “I think that’s great, and also important, because it makes things much easier for me—for example, if I don’t understand something the first time I tackle a topic.”

Meanwhile, MTU Maintenance Serbia has expanded its training portfolio. “Together with Serbian vocational schools and academies, we’re currently setting up a dual-track training system based on the German model,” Triebenbacher says. “In the long term, we want to be able to train our skilled workers locally, of course.” Specifically, the focus is on training people to be aircraft maintenance engineers, industrial mechanics, CNC operators, inspectors, and welders.

Triebenbacher: "Although we are now highly independent, we continue to share experiences and learn from each other across locations. Knowledge is nothing if it is not shared, so as standards are set every day, we continue on the path to business excellence.”

“One of the most important things in our business is to make sure our colleagues on the lines can apply their theoretical knowledge without making mistakes. With the Quality Escape Room, we do this in a playful way—but with real-life topics.”

Responsible for training programs at EME Aero

Jasionka, Poland

Didactics not only imparts knowledge, but also promotes teamwork, a sense of responsibility, a solution-oriented approach, and mutual respect. Skills that are essential in engine maintenance as well.

That’s exactly the thinking that Łukasz Zając, who is in charge of the training programs at EME Aero in Jasionka, Poland, and trainer Dominik Weber share. “One of the most important things in our business is to make sure our colleagues on the lines can apply their theoretical knowledge without making mistakes,” Zając says. “With the Quality Escape Room, we do this in a playful way—but with real-life topics.”

It is embedded in the EME Campus, one of the largest training facilities in the MTU network. Constructed in the style of an independent service workshop, the 4,000 square meter facility is equipped with all the tools and systems that EME Aero uses to maintain the engines of its global fleets.

It was inaugurated in 2023 to cope with the ever-increasing number of shop visits and at the same time ensure the qualification of the EME Aero team. “In this way, we’ve separated the most important service work from the training process and created a space dedicated to on-the-job training,” Zając says.

Part of the training is the Quality Escape Room game for all new employees. With the support of the quality team, this is the last step before they enter the EME Aero facility and start their work.

“In the Escape Room, a group must solve various tasks and puzzles to find the key to the exit and leave the room in as little time as possible,” explain Daria Witek and Natalia Fudali, both Quality Engineers and Auditors at EME Aero. In this case, the key topic is quality and the associated aspects of daily work.

Once the door to the six-by-five-meter box has closed, a small group has eight minutes to mark ten “findings.” “A ‘finding’ could be an expired chemical, a foreign object on the floor, or a tool that’s been put away incorrectly,” Weber explains. When the door opens again, the trainer and the group talk through all the “findings,” both identified and overlooked. “We’ve built up a pool of around 60 ‘findings’ we can choose from depending on the group.”

Since the beginning of the year, EME Aero colleagues who don’t work directly on the engines have also been able to book a certain number of slots for the Escape Room. “A high level of awareness of quality issues is necessary in all other jobs at our company as well,” Zając says.