aviation

MTU Maintenance Zhuhai’s world-class MRO shop keeps on growing

MTU Maintenance Zhuhai began operations twenty years ago and has been growing ever since. Following recent expansion of both shop and capacity, a second facility is now in the pipeline.

author: Nicole Geffert | 5 mins reading time published on: 06.04.2021

author:

Nicole Geffert

has been working as a freelance journalist covering topics such as research and science, money and taxes, and education and careers since 1999.

When Jaap Beijer steps onto the MTU Maintenance Zhuhai premises, he sees progress. “We completed our expansion of the facility in late 2020, increasing our capacity by 50 percent to 450 shop visits a year,” says the President and CEO of MTU Maintenance Zhuhai. The successful 50/50 joint venture between MTU Aero Engines and China Southern Airlines Company Limited was established 20 years ago. Since then, business has been growing for the company favorably located in the Pearl River Delta Metropolitan Region, one of China’s economic heartlands.

From the moment the first concrete strut was laid for the foundation back in May 2001, MTU Maintenance Zhuhai has gone from strength to strength. It is now the leading provider of engine maintenance, repair and overhaul (MRO) services on the Chinese market and has carved out a position for itself as a specialist for CFM56 and V2500 engines. In 2019, the company added LEAP engines to its portfolio. The recent expansion of the site enlarged the shop by some 10,700 square meters, providing additional plant and office space as well as a sports area and parking for employees.

Although it’s still early in the year, Beijer and his team are optimistic about what 2021 will bring. “As market demand increases again following the acute phase of the Covid-19 crisis, we’ve been gradually ramping the MRO shop back up to full capacity,” Beijer says. “We’re now operating at nearly 100 percent once more.”

Designed with growth in mind

Senior project manager Anna Küpper helped plan and oversee the shop expansion. “The project was new territory for me and I found it really inspiring,” says the mechanical engineer, who relocated to MTU Maintenance Zhuhai from MTU Aero Engines in Munich in 2019. In the planning and construction stage, she kept in close contact with the production specialists at MTU Maintenance Zhuhai as well as the specialized department back at MTU in Munich to take advantage of its expertise and experience in construction projects.

“We had plenty of space to enlarge the shop. MTU Maintenance Zhuhai was designed with growth in mind,” Küpper says. Due to steadily increasing demand for MRO services in the Asian market, the shop was expanded in 2012 to increase its capacity by 50 percent, or from 200 to 300 shop visits a year. The employees who oversaw that project are still around and were able to bring their know-how to the table for this latest expansion.

Business as usual during expansion

Normal operations continued as the teams expertly managed the expansion of the shop, office space and warehouse. “We left the outer wall standing as long as possible,” Küpper explains. “Once it was gone, heavy-duty tarpaulin prevented any dust from the construction site from entering the operational area.” It also kept out the rainwater, which was important given that the construction stage took place during typhoon season.

The teams have now moved into the offices and the shop will be relocated in due course. “All the machines and workstations that can be moved will get a new home now that the expansion is complete,” Küpper says. A sophisticated shop layout was devised for the high-tech machinery to ensure that shop visits are cost-effective with short turnaround times.

Expansion: The site expansion has been completed and existing capacity increased by 50 percent to 450 shop visits a year.

Having received expert training, employees carry out 80 percent of parts repairs in-house. The facility’s machinery is state-of-the-art, and the test cell has an impressive 150,000 pounds of thrust capacity. Late last year, the shop completed its 3,000th shop visit—a V2500 operated by joint venture partner China Southern Airlines. MTU Maintenance Zhuhai serves more than 70 customers from China, other parts of Asia and around the world.

MRO network partner for the PW1100G-JM

And the company just chalked up another success: a high-profile newcomer, the Pratt & Whitney GTFTM PW1100G-JM that powers the Airbus A320neo, will soon be joining the other best-selling engines in the shop. This means the location is now a member of the global network of providers entrusted to maintain the engine on behalf of Pratt & Whitney.

Beijer and his team are well prepared for this new challenge: “We’ve already started ramping up PW1100G-JM capacity,” he says. The engines are expected to start coming into the shop in mid-2021, with 1,000 shop visits planned in the next ten years. “We’re the leading provider of MRO services for narrowbody engines in Asia,” Beijer explains. “Adding the PW1100G-JM to our product mix will enable us to continue our growth strategy and better serve the Asian market.”

"We’re the leading provider of MRO services for narrowbody engines in Asia.”

President and CEO of MTU Maintenance Zhuhai

MTU Maintenance Hannover and EME Aero in Poland, a joint venture between Lufthansa Technik and MTU, already support the PW1100G-JM. Part repairs for the engine are also in the best of hands at MTU Maintenance Berlin-Brandenburg and MTU Aero Engines in Munich. “Zhuhai will be the third facility within the MTU network with full disassembly, assembly and test capabilities for the PW1100G-JM,” says Michael Schreyögg, Chief Program Officer at MTU Aero Engines. “We’re well prepared for the recovery of commercial aviation and will leverage the extensive experience we’ve already gained with this engine to further cement our reputation as MRO experts.”

On the test stand: A V2500 engine is prepped for test runs.

Additional facility in Jinwan District

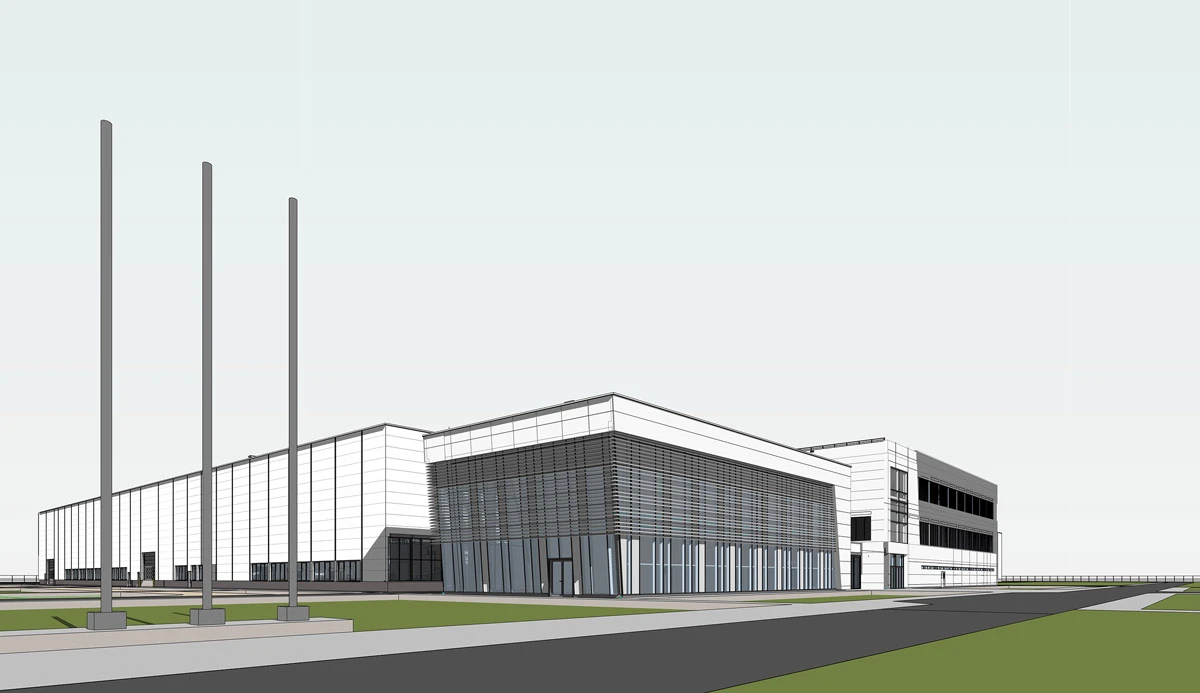

In line with this approach, MTU Maintenance Zhuhai plans to establish a second facility in neighboring Jinwan. The shop will specialize in Pratt & Whitney narrowbody engines, accommodate a test cell with a 65,000 pound thrust capacity and, according to current estimates, have a workforce of around 600 qualified employees. A clear plan is in place: the shop will initially offer capacity for 250 shop visits a year and is expected to start operations in 2024.

Jinwan-District: MTU Maintenance Zhuhai plans to build a second facility in Jinwan, which is expected to start operations in 2024.

“Its close proximity to MTU Maintenance Zhuhai will enable significant knowledge transfer and synergies between the two facilities,” says Beijer, who will be in charge of both sites. And MTU Maintenance Zhuhai’s unwavering focus on growth certainly doesn’t end there. Such determination perfectly reflects the Buffalo in the Chinese zodiac, whose characteristics are strength, hard work, patience and perseverance. Fitting, given that the Chinese Year of the Buffalo begins on February 12, 2021.