aviation

Slow but efficient: airships for new markets

To date, very few airship plans have managed to mature past the idea stage. Recent projects could change this: they are targeting the right market niches.

author: Denis Dilba | 6 mins reading time published on: 01.04.2018

author:

Denis Dilba

holds a degree in mechatronics, is a graduate of the German School of Journalism, and founded the “Substanz” digital science magazine. He writes articles about a wide variety of technical and business themes.

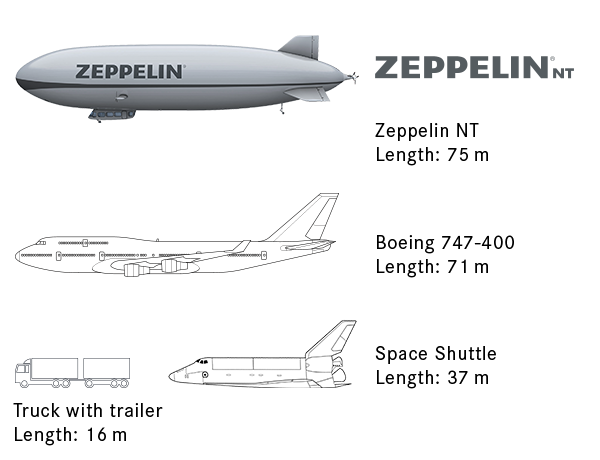

The quiet hum of the engines can’t be heard from the ground. For the observer, the “cigar” floats silently and at a majestically leisurely pace some 300 meters above Lake Constance. When the weather is really good, the panoramic windows reveal breathtaking views as the airship moves with the gentle rise and fall of the thermals: the Alpine peaks, the Black Forest and the Swabian Jura are so close you can almost reach out and touch them. “Our passengers often compare the gentle free-floating with a combination of diving and a ship gently rolling with the waves,” says Franz Günther, chief pilot of the German Zeppelin Transport Company and flight operations manager for the Zeppelin NT. This airship, stationed in Friedrichshafen, has already delighted more than a quarter of a million passengers worldwide with a new perspective of the world from above since it began commercial flights in 2001. “Our flight operations are economically sustainable and profitable,” says Eckhard Breuer, Günther’s boss, visibly pleased.

Zeppelin NT This airship, stationed in Friedrichshafen/Bodensee, has already delighted more than a quarter of a million passengers worldwide.

Development costs underestimated

That is precisely what a whole host of other companies that want to conquer new markets and make big bucks with airships dream of doing. They want to shake up the transportation sector with their new designs, guard borders from the air, create flying research platforms and communication networks, or transport wealthy tourists to remote locations. Uwe Apel, a professor of aerospace engineering at Bremen University of Applied Sciences, is familiar with all these concepts. “There have been many interesting ideas in past decades, but despite their great potential, to date, most of them have remained just that: namely ideas,” says the expert. Apel considers one main reason for this to be the chronic underestimation of the development costs for these unusual flying machines: “They are comparable to those for an airplane.”

What makes it expensive isn’t the aluminum or the high-tech envelope, but the process to get the systems certified as safe, Apel explains. In principle, the cost of development can be roughly estimated based on the empty weight of an aircraft: “Rarely will it be possible to develop something for under 40,000 euros per kilogram,” says Apel. This, among other things, was also the problem with the most famous of the recent airship projects. In the late 1990s, the CargoLifter was to become the largest airship ever built, with a massive length of 260 meters and a net weight of 260 tons—as much as the Airbus A380. “So they should have been budgeting for several billion euros,” says Apel. CargoLifter set development costs at half a billion. “There are no measures that would let them recoup that later,” says Apel.

Economical transportation means for remote areas

But that doesn’t have to mean that all future airship projects are doomed to fail, says Apel. “Airships are practically predestined for certain tasks, especially supplying remote areas.” These remote areas, such as settlements in Alaska or Canada, can be accessed via ice roads in winter and by transport aircraft in summer. However, climate change is causing the connecting ice roads to melt away ever faster and establishing a road infrastructure isn’t worthwhile. Airships require very little infrastructure for taking off and landing—and they are also cheaper to operate than airplanes so it makes good business sense to use them to close this supply gap. The prerequisite for success is always the same, says Apel: “Airships have to perform the task better than the transportation means that currently performs it.”

British company Hybrid Air Vehicles is even convinced that its Airlander 10 isn’t just better at performing these kinds of supply flights and guarding borders, but that it is virtually unrivaled. This owes to its construction design—it is currently the largest airship in world, with a length of 92 meters. And it is a hybrid airship. In contrast to normal airships, which float because they are charged with gas, the hybrid generates some of its lift in much the same way the wing of an airplane does, by virtue of its shape, despite being heavier than air. As a result, unlike its relatives, this wide, bulbous giant—which looks like multiple airships nested within each other and goes by the nickname “flying bum”— simply descends when it is no longer in motion. This makes takeoffs and landings less complicated. Conventional airships require a mooring mast and an area the size of a circle with a radius equal to the airship’s length, and they must be parked with their nose into the wind, which can come from any direction.

U.S. technology giant Lockheed Martin wants to leverage the advantages of these hybrid airships, too. According to the company, their 82-meter-long prototype LM-H1 is in the construction phase and is on track for completion in 2018. Flying Whales, a French company, says its LCA60T prototype will be in the air a year later. CEO Sébastien Bougon says its behemoth will be 140 meters long and have a carrying capacity of up to 60 tons. It is intended primarily for transporting wood away from inaccessible terrain, but Bougon can also imagine it being used to hoist wind turbines or power lines onto mountain peaks, or to transport prefab houses or large aircraft components. “That all sounds very nice, but apart from Hybrid Air Vehicles, no other company has produced a flying prototype,” says Apel. And the Brits have yet to demonstrate that their design really lives up to its promise. The company most recently made headlines with two accidents involving its airship.

The airship projects of internet billionaires

The idea that Amazon patented in the U.S. in 2016 could therefore, at first glance, be classed as science fiction: the online retailer envisions serving its customers from huge airships that float permanently at an altitude of around 13 kilometers above cities, with drones transporting the goods. While a floating warehouse like this is doubtless an extreme technological challenge, experts don’t consider the vision impossible, but it is still entirely unclear whether and when Amazon will launch such a delivery service. Amazon boss and multibillionaire Jeff Bezos certainly would have the resources. According to rumors, though, Bezos’ billionaire colleague, Google co-founder Sergey Brin, has a concrete project in the pipeline. U.S. news agency Bloomberg claims to have learned that something resembling a massive Zeppelin is currently being built in one of the world’s largest airship facilities in Mountain View, California. It could be an XXL luxury liner. Brin himself is silent on the matter.

As vague as the prospects are at the moment, bets on the future could potentially pay off faster than we think: “If stricter environmental regulations are passed, airships will have a distinct advantage,” says Apel, because “they are extremely resource efficient in flight.” Perhaps then Zeppelins will go back into series production in Friedrichshafen—where everything began with the first flight of the LZ 1 airship nearly 120 years ago.