good-to-know

In a nutshell: Sustainable aviation fuels

Sustainable aviation fuels (SAFs) have the potential to greatly reduce aviation’s climate impact. They could already be used as “drop-in” fuels to power the existing fleet sustainably. Five questions about SAFs.

author: Isabel Henrich | 2 mins reading time updated on: 18.06.2025

author:

Isabel Henrich

studied political science and communications. At MTU, she coordinates the editorial process of AEROREPORT and is responsible for the conception and development of its content.

What are sustainable aviation fuels (SAFs)?

SAFs are sustainable fuels that greatly reduce aviation’s climate impact. They can be divided into two categories:

- fuels that are produced using biomass.

- synthetic fuels produced using renewable energy and CO2.

What SAF manufacturing processes have already been approved?

SAFs are currently manufactured mainly from biogenic residues by hydrogenating vegetable or animal fats and oils into kerosene, also known as hydroprocessed esters and fatty acids (HEFA). In addition to this approach, there are seven other approved methods based on different raw materials and processes.

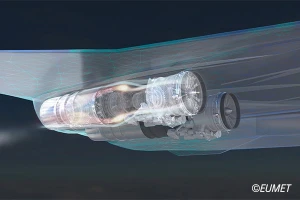

Power-to-liquid (PtL) is considered a promising option for manufacturing synthetic SAFs. In the PtL process, hydrogen is produced using electricity from renewable sources such as wind or solar power. It is then synthesized with CO2 to form hydrocarbons, which are processed into liquid fuel. MTU is supporting several projects to set up power-to-liquid production facilities.

What are the advantages of sustainable aviation fuels?

SAFs have a much smaller impact on the climate than kerosene from fossil sources, even though they fulfill the same requirements. The logic behind SAFs is that the CO2 emitted in flight is recycled in the production of the fuel, thus creating a CO2 cycle that is as closed as possible. To this end, the CO2 must first be extracted from the atmosphere in the best possible way. Another positive effect is that the combustion of SAFs produces fewer soot particles. These are partly responsible for the formation of contrails, which in turn contribute to global warming alongside CO2 and nitrogen oxides. Today’s SAF production processes are based either on biomass or on renewable energy and CO2. However, the quantity of SAF actually used is currently still far too low. This is mainly due to its significantly higher price tag.

What role does hydrogen play?

Kerosene is a hydrocarbon, a compound of hydrogen and carbon. Hydrogen is therefore a key raw material in the production of SAFs. In producing PtL SAFs, electrolysis powered by renewable electricity is used to make hydrogen from water. Future propulsion concepts could potentially also use hydrogen directly—a gas turbine with hydrogen combustion, for example, or a fuel cell. That means complementary use of hydrogen and SAF in aviation could open up synergies. Over long distances, SAFs may have advantages over hydrogen, but over shorter distances, fuel cells show great potential: this concept is virtually free of emissions. That’s why MTU is developing the Flying Fuel CellTM.

What is the demand for SAFs in aviation?

If we want to achieve climate-neutral aviation by 2050, then the widespread introduction of SAF is a fundamental prerequisite. Current forecasts assume a demand of around 600 million metric tons per year. However, in 2024, only around 0.3 percent of the industry's global fuel demand was covered by sustainable fuels. That’s why the European Union (EU) adopted the ReFuelEU aviation initiative, which sets a minimum proportion of SAFs for all flights from EU airports. ReFuelEU aviation obligates fuel suppliers to ensure that the share of SAFs reaches 2 percent by 2025, 6 percent by 2030, and 70 percent by 2050. For synthetic fuels, a quota of 1.2 percent will apply starting in 2030; this will increase to 35 percent by 2050. Other countries are also making efforts to increase the proportion of SAFs. In the U.S., the main focus is on providing incentives through the Inflation Reduction Act, whereby fuel suppliers receive tax breaks if they sell SAF.

The aim of all these measures is to create a binding framework to stimulate demand. Another reason why SAFs aren’t yet a true alternative on the market is that they’re significantly more expensive than fossil kerosene.