aviation

Turbine Alexandra all fired up for the Stadtwerke Erfurt!

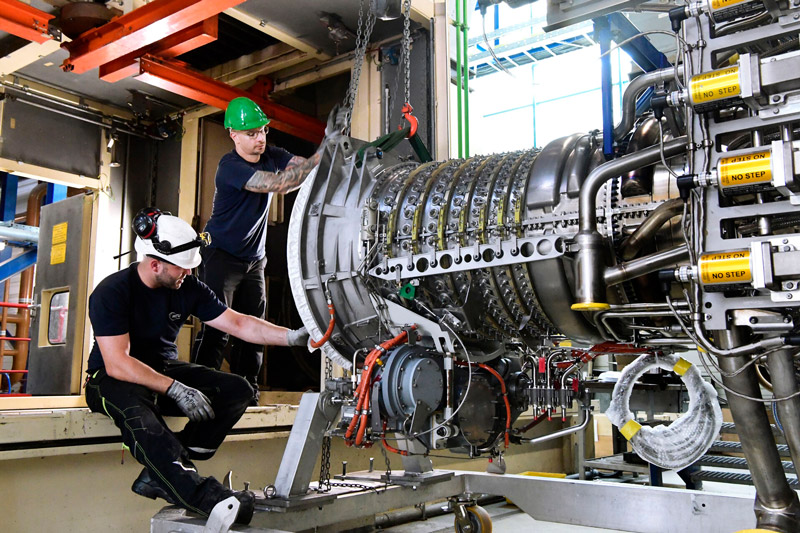

MTU Power installs the first ever LM2500 DLE (15ppm NOx) in Europe on behalf of long-term partner Stadtwerke Erfurt. The new turbine is significantly more efficient and helps the customer go above and beyond federal emissions requirements.

12.2020 | author: Victoria Nicholls | 2 mins reading time

author:

Victoria Nicholls

is a specialist for aftermarket topics such as engine MRO, leasing and asset management, as well as international market trends. The British-born editor lives in Berlin and works for MTU’s corporate communications in Hannover and Ludwigsfelde.

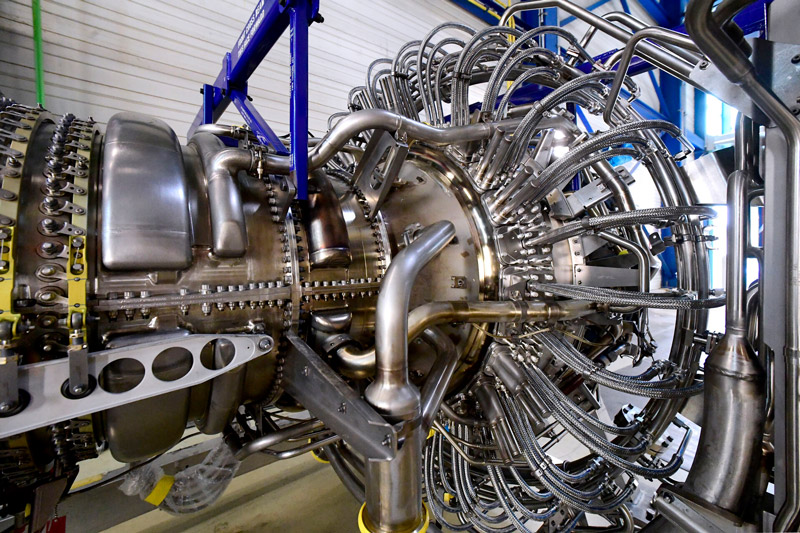

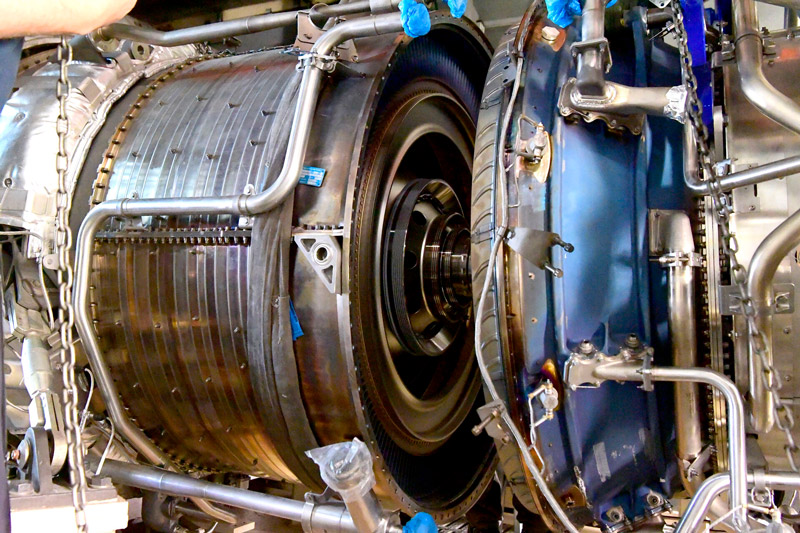

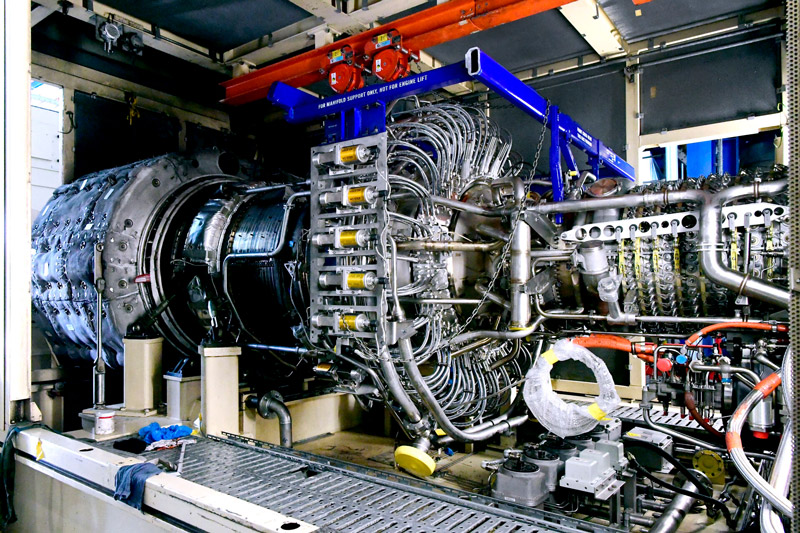

Alexandra, a LM2500 DLE 15ppm NOx (parts per million) gas turbine, has just entered commercial operation at the Stadtwerke Erfurt, a municipal energy provider in Thuringia, Germany. This turbine is the first of its kind in Europe and the highest LM series technical specification available on the market. “The turbine produces a mere 20 percent of the emissions of its predecessor,” says Janko Matheussik, Project Manager, MTU Power. “This goes above and beyond the necessary reduction in emissions mandated by the German federal government and is significantly more efficient.”

Because of the German governments ambitious emissions and efficiency targets, the Stadtwerke Erfurt exchanged an LM2500 SAC engine after just 20 years, although gas turbines typically have a much longer lifetime. “In order to be as sustainable as possible, we decided to replace the turbine, but keep as much of the package as possible,” says Marco Tuerke, head of power generation, Stadtwerke Erfurt. And it is an important task. The power plant provides over 40,000 households with heat energy in the surrounding region.

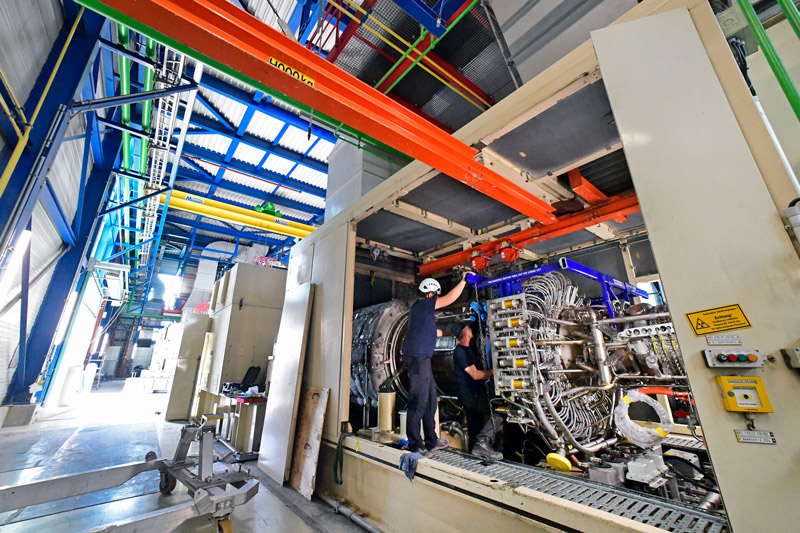

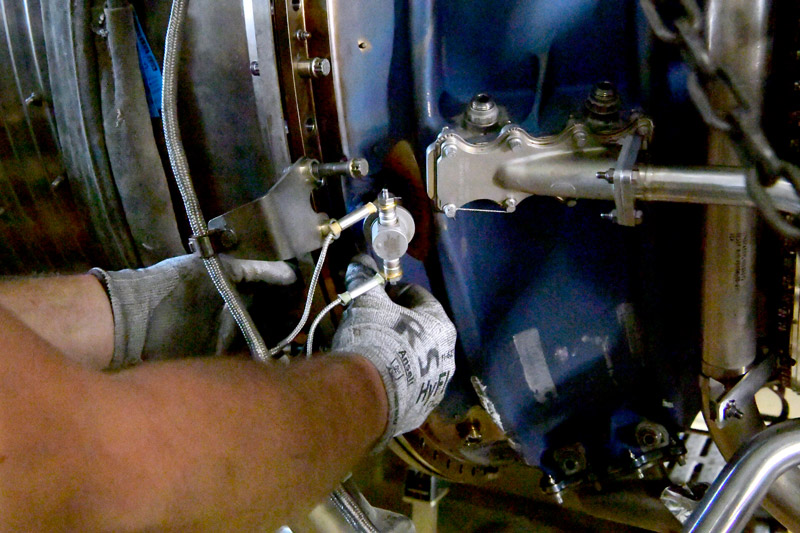

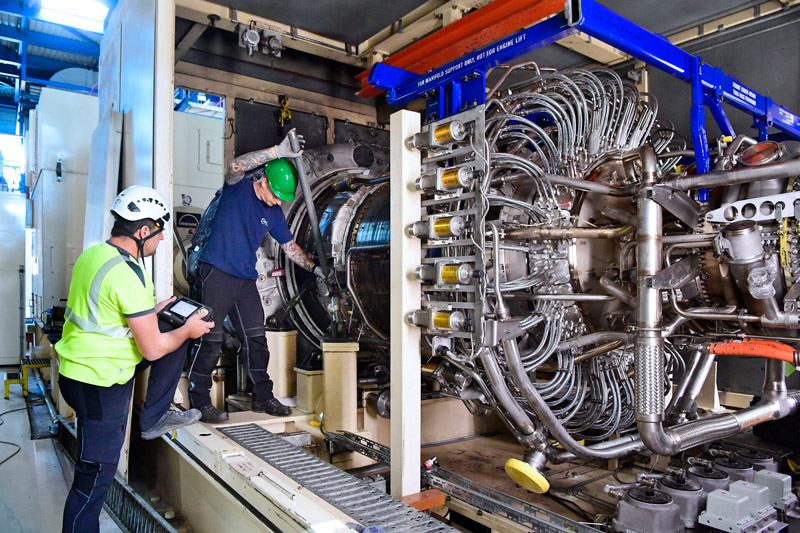

“Old systems that were no longer needed, such as the water injection system and liquid fuel system, had to be removed,” explains Christian Zierold, Project Buyer MTU Power. Further, the control system was upgraded to the state of the art Woodward control Micronet+ system. The gas turbine compartment was also completely gutted and modified to suit the new turbine.

Beyond this, the gas system was also renewed: a new fuel metering skid was added, shut off valves and gas relief valve exchanged and repositioned, as well as gas piping renewed and rerouted and a calorimeter for gas analysis installed. Additionally, by-pass ducts on the filter house needed installing to reduce inlet pressure losses. Then the new turbine had to be installed and the new model be made to fit the space the older turbine had occupied.

The package modification and installation of “Alexandra”, named after the power plant manager’s daughter at the time of initial installation, was a milestone project in a long and successful partnership between MTU and the Stadtwerke Erfurt. In fact, it is because of an MTU employee that each turbine in the power plant bears a female name. “Back in 1999, my daughter Annabell was born,” says Johannes Hölzle, Field Engineer for MTU Power. “It happened during a turbine installation project and the power plant manager at the time was so taken by the event that he named the turbine after my daughter.”

Annabell is due to be exchanged during Summer 2021, when MTU Power will be carrying out an installation and remodification project for the sister unit. Both LM2500 DLE (15ppm NOx) turbines significantly surpass current emissions requirements and are an investment in the future for the Stadtwerke Erfurt. The MTU Power team will be supporting their valued customer with all Annabell and Alexandra’s maintenance, repair and overhaul needs for the coming ten years of their journey.