good-to-know

A brief guide: How the WET concept works

The Water-Enhanced Turbofan can run on kerosene, sustainable aviation fuels (SAFs), or hydrogen, and is suitable for use on short-, medium-, and long-haul routes.

05.2024 | author: Isabel Henrich | 2 mins reading time

author:

Isabel Henrich

studied political science and communications. At MTU, she coordinates the editorial process of AEROREPORT and is responsible for the conception and development of its content.

What is the WET concept?

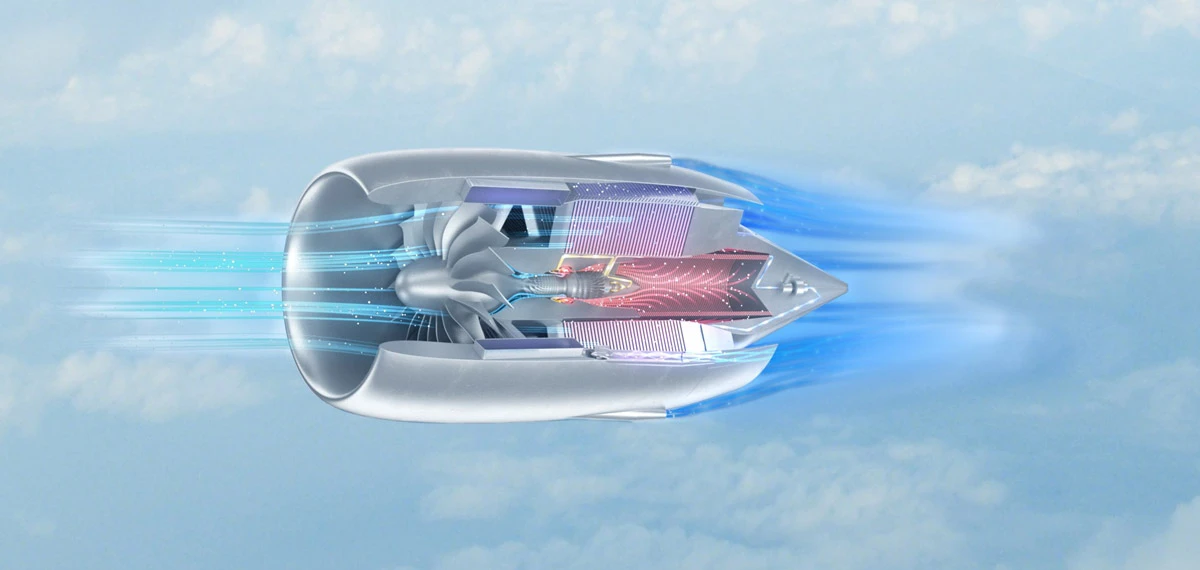

The Water-Enhanced Turbofan (WET) is a gas-turbine-based propulsion concept that utilizes residual heat from the engine’s exhaust gas stream. It uses a steam generator to vaporize water, which is then injected into the combustor. The water for this is extracted from the exhaust gas by means of a condenser and then separated.

What are the benefits of the WET concept?

Recirculating residual heat promises to increase engine efficiency, while wet combustion should lead to a massive reduction in nitrogen oxide (NOx) emissions. The WET concept should facilitate an overall reduction in fuel consumption, CO2 emissions, NOx emissions, and the formation of contrails.

Using hydrogen to power WET would bring further advantages—not only lower climate-relevant emissions, but also potential reductions in the weight and drag of the propulsion system resulting from a more compact design. This is because the heat exchangers the concept requires could exploit the cooling potential offered by ultracold hydrogen.

Water-enhanced turbofan: With the Water-Enhanced Turbofan, MTU is working on a revolutionary gas-turbine-based concept. It can run on kerosene, sustainable aviation fuels (SAFs), or hydrogen, and is suitable for use on short-, medium-, and long-haul routes.

How does the WET concept work?

The engine’s efficiency is increased by recovering the exhaust energy that would otherwise be lost. First, a steam generator produces hot steam. The exhaust gas cools down in the process. As it cools further in the condenser, the water it contains begins to condense. The condensation heat is fed to the bypass flow and the liquid water is separated from the exhaust gas in a water separator. Condensation nuclei are also washed out of the exhaust gas in the process, which reduces the formation of contrails. The water is then brought to a high pressure level by means of a pump and delivered to the steam generator. The steam expands in a steam turbine before being channeled into the combustor. The power is fed into the low-pressure shaft. Injecting the hot steam into the combustor not only increases the engine’s efficiency, but also reduces nitrogen oxide (NOx) emissions.

Where can WET be used?

The Water-Enhanced Turbofan can run on kerosene, sustainable aviation fuels (SAFs), or hydrogen, and is suitable for use on short-, medium-, and long-haul routes.

WET concept: This concept utilizes heat recovery and wet combustion and can be applied in all thrust and power categories.