innovation

Fire-resistant and lightweight: Aviation textiles

Seat covers, safety belts and carpets used in aircraft must be flame-retardant and lightweight. In the future, high-tech fabrics will fulfill a broader range of applications.

author: Denis Dilba | 8 mins reading time published on: 01.07.2018

author:

Denis Dilba

holds a degree in mechatronics, is a graduate of the German School of Journalism, and founded the “Substanz” digital science magazine. He writes articles about a wide variety of technical and business themes.

At almost 1,000 degrees Celsius, yellow-orange flames shoot out of the blowtorch to a length of some 30 centimeters. For nearly two minutes now, the flames have been relentlessly barbecuing the aircraft seat from the left-hand side. Then, after precisely 120 seconds, the torch goes out. Any remaining pockets of embers are immediately extinguished and a light veil of smoke fills the test cabin. Once it clears, we can see the extent of the damage. How much remains of the seat cushion, backrest and cover will decide whether or not this particular mix of materials will get its wings. As per FAR/CS 25.853, the flammability regulation that applies to Europe and the United States, the fire must not spread more than 43.2 centimeters from the source. That’s the width of the narrowest aircraft seat.

“All textiles used in aircraft cabins must be flame-retardant,” says Daniela Grunder, Director Brand Communication & Product Management at Lantal Textiles AG. Based in Langenthal, Switzerland, the company specializes in fabrics for the aviation industry and manufactures products including seat covers, carpets, curtains and wall coverings. All the major aircraft manufacturers as well as more than 300 airlines—including Swiss Air, Lufthansa, Delta and China Airlines—place their trust in the expertise of this company located in the Canton of Bern. This makes Lantal a world leader in its industry.

Every decigram counts

According to Grunder, having flame-retardant properties is just the first requirement fabrics must fulfill if they are to be used in aircraft cabins. “Aircraft textiles should also be wear-resistant, stain-resistant, non-toxic and—most importantly—as light as possible,” she says. After all, the lighter the aircraft, the lower the airline’s fuel consumption and, in turn, its CO2 emissions. Extrapolate that to the level of an entire fleet of some 100 aircraft and reductions of even a tenth of a gram per seat cover can quickly result in six-figure savings. Still, more lightweight textiles have their drawbacks; for example, a slimline aircraft carpet is thinner and often less resistant to wear than its heavier counterparts. Plus, the more lightweight versions tend to get dirtier faster.

Look and feel

Another key factor for seat upholstery is that it feels good against the skin. Wool does this best, partly because it absorbs moisture and as such doesn’t feel “sweaty,” Grunder explains. But compared to artificial fibers like polyamide or polyester, fabrics made from natural fibers can be heavier. “Given the many, often varying, requirements that aircraft textiles must fulfill, there is no one best fabric or carpet for every case,” Grunder says. “The decision as to which material or material blend gets used and where depends on the individual customer’s requirements.” While one customer might place greater emphasis on comfort, another will be more concerned with reducing fuel consumption—and yet another will want both.

But occasionally it’s simply a matter of taste: when it comes to carpets, European airlines almost always favor products with a very high wool content, while US airlines are just as adamant about having the synthetic material polyamide. “A more technological look simply goes over better in that market,” Grunder says. A blend of wool and polyamide is the standard for seat covers, with wool fibers accounting for 89 to 95 percent of the fabric. Grunder says polyester’s use in seat upholstery is dependent on being combined with what are known as fire-blocking materials. This may for instance be Kynol®, a special heat- and flame-resistant fiber used for electrical insulation in high-performance electronics as well as other applications.

Fighting fire with physics

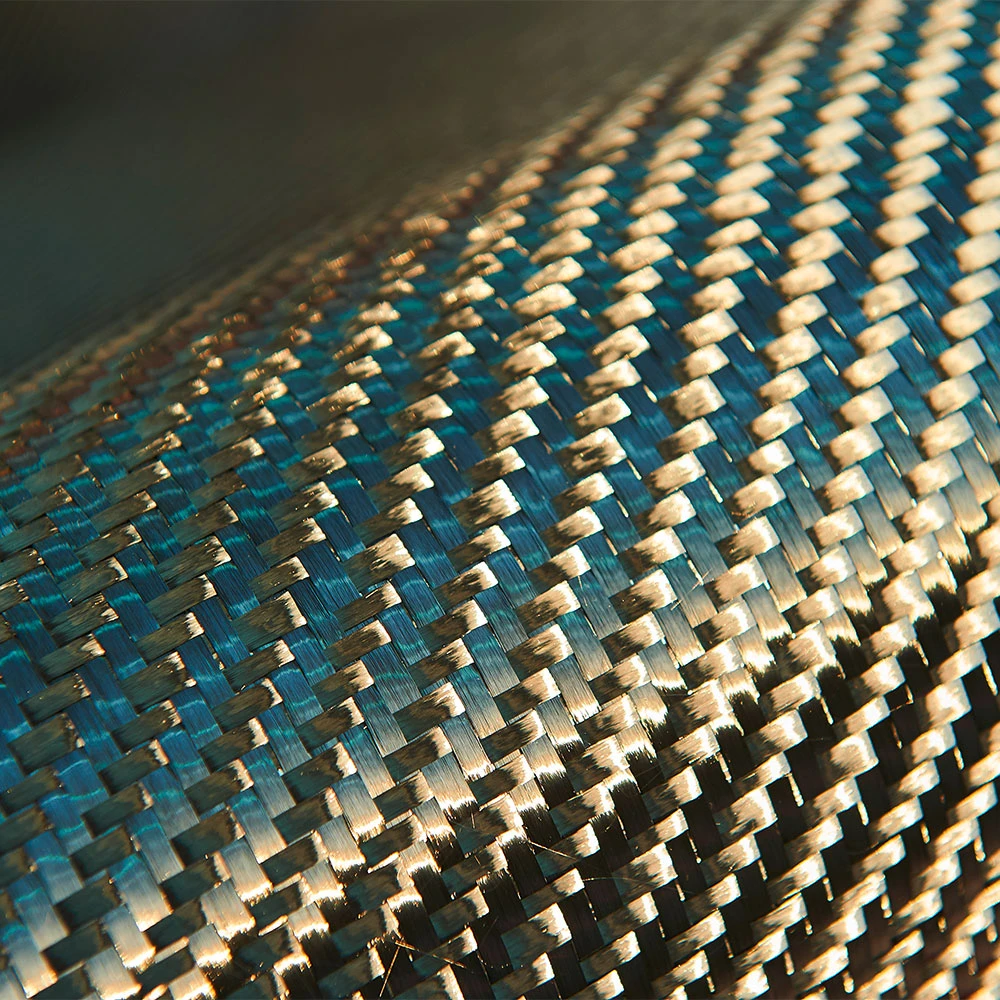

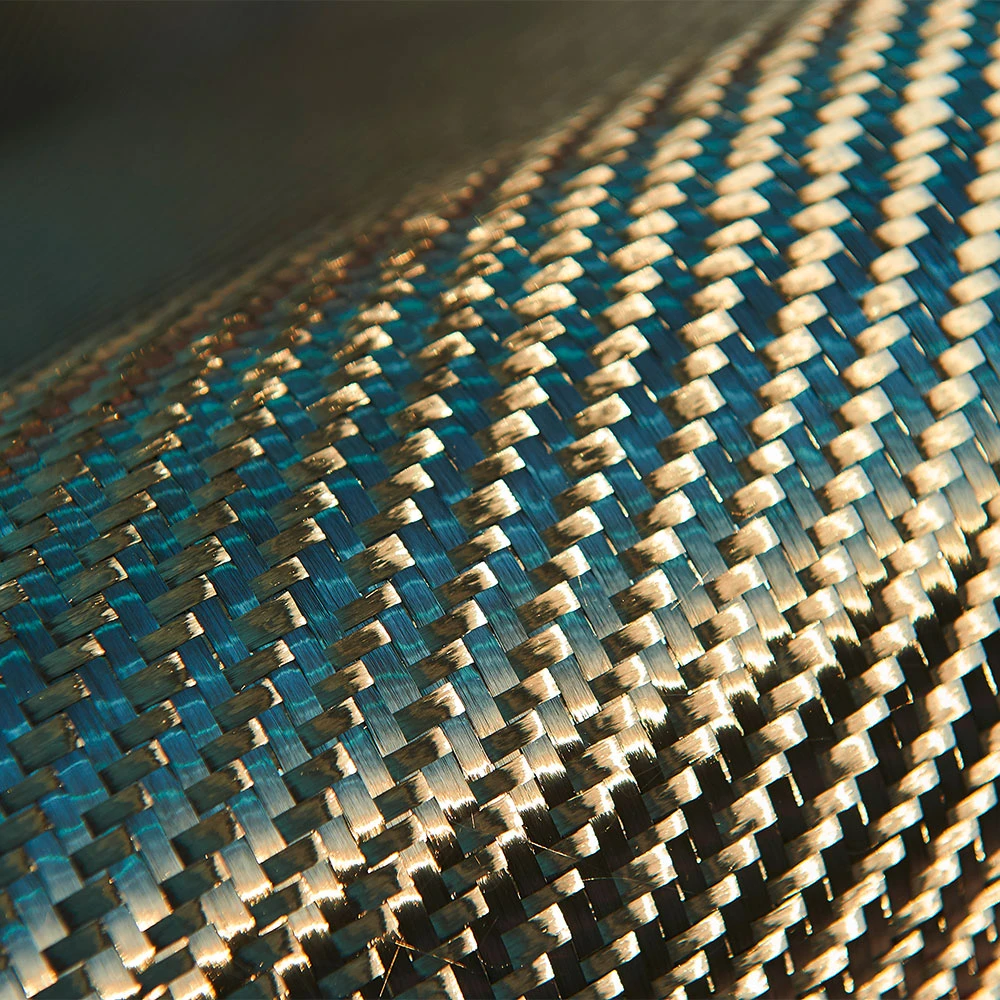

What sets this high-performance textile apart is its high limiting oxygen index, or LOI for short. Expressed as a percentage, this describes the oxygen concentration in the air at which the fibers start to burn. Kynol® has an LOI of 30. Oxygen generally makes up 21 percent of the air we breathe; at that concentration, this special fiber won’t even smolder. Wool has an LOI of 25. This is why polyamide and polyester—with their LOI of 20—are blended with a very high proportion of wool; it’s the natural material that makes this fabric flame-retardant. “How well textiles burn can, however, be influenced by the technology used to make them,” says Wilko Reinck, Chief Aviation Engineer at safety belt manufacturer Schroth, based in Neheim, Germany. “Tightly woven fabrics allow very little oxygen to reach the surface of the fibers, which keeps fire from spreading.” In addition, technical weaves can be given a flame-retardant coating. This is just one method Schroth employs to make its polyester safety belts fire-retardant as well as extremely mechanically robust: its belts can withstand loads of at least 2.2 metric tons.

Safety and security thanks to the Fly-Bag

If worst comes to worst, even higher demands are placed on the four-layer aramid fibers used in the Fly-Bag. Made from the same fiber used in the better-known DuPont brand Kevlar®, this flexible luggage container is designed to provide protection from explosions. The basic idea is that items of luggage or suspicious objects are placed inside the Fly-Bag. Should a hidden explosive device detonate, the high-tensile layers of heat-resistant aramid make sure the blast waves, heat and shrapnel remain inside the bag. “What the Fly-Bag does is dissipate the energy of the explosion, which in turn prevents the aircraft from sustaining major damage such a hole in its fuselage—the very thing that caused the Lockerbie air disaster in 1988,” says Heike Illing-Günther, Research Director at the Sächsisches Textilforschungsinstitut (STFI), Chemnitz University’s institute of textile research. Illing-Günther, who played a major role in the development of the Fly-Bag, believes that a compact version for use in the aircraft cabin could enjoy success on the market.

Look and feel Seat covers for aircraft can be made of a wide range of materials, from blended fabrics containing wool, rayon and synthetic fibers to leather.

High-Tech straps Seat belts in aircraft must of course have high tensile strength, but they must also be resistant to light and acids, have flame-retardant properties and keep their shape.

“In addition to being lighter than the large versions, the main advantage of a small Fly-Bag is that it wouldn’t affect loading procedures,” she says. The larger safety bags designed for the hold add at least one step to the process: the cargo has to be put into the bag, which must then be sealed. This costs time, which is enough for the airlines to reject the idea. A small Fly-Bag wouldn’t have to be loaded, making it simply another way to increase safety. “If an unclaimed object—say a mobile phone—is found in the cabin after takeoff, current safety protocol is for the aircraft to land immediately,” says Illing-Günther. But if the crew could put the suspicious object in a small Fly-Bag, the airline would have the option of allowing the flight to proceed as planned.

Smart textiles

Regardless of whether the Fly-Bag makes it on board, Thomas Stegmaier, Research Director for technical textiles at the German Institutes of Textile and Fiber Research Denkendorf, says we can all expect a great deal from the development of textiles for aircraft applications. “What’s going to be really interesting are smart textiles with additional functions,” says Stegmaier. Take the work currently being done on self-illuminating textiles, which incorporate metal fibers that emit light when electrified. “Upholstering the aircraft cabin ceiling with this kind of fabric would mark a significant reduction in weight,” says Stegmaier. “Ultimately, that’s what all developments in textile technology are trying to achieve.”