aviation

Aviation expertise in Poland

Poland is an attractive location for the aviation industry. The MTU site in this country is growing fast. And now a new joint venture has been founded.

01.2018 | author: Thorsten Rienth | 6 mins reading time

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

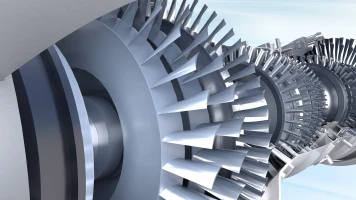

Under normal circumstances, managers are advised to keep a rein on their emotions. But there are also times when a display of emotion is perfectly acceptable. Dr. Uwe Zachau could not hide his enthusiasm a moment longer. He speaks of a milestone for both companies, an ambitious ramp-up plan, an excellent and highly motivated team. Zachau is describing a new maintenance, repair and overhaul (MRO) joint venture between Lufthansa Technik and MTU Aero Engines that bears the name Engine Maintenance Europe or EME Aero for short. Zachau is the COO of the new company; Derrick Siebert the CEO. He says: “We are paving the way for MRO of the new generation of Geared Turbofan™ engines in Europe.” Both partners hold a stake of 50 percent in the new company.

The joint venture will be located in Poland, where MTU has already been able to gather many years of experience. In 2007, the company set up MTU Aero Engines Polska in a special economic zone in the southeast corner of the country. “This zone is the economic powerhouse of the region,” says the regional administration. Many well-known companies have opened branches with production and research facilities there. The original plan was to stop offering business advantages in the Polish special economic zones in 2020. But the special rights granted to these zones have now been extended up until 2026. Almost every month, new firms are moving in.

Region with a tradition in aviation

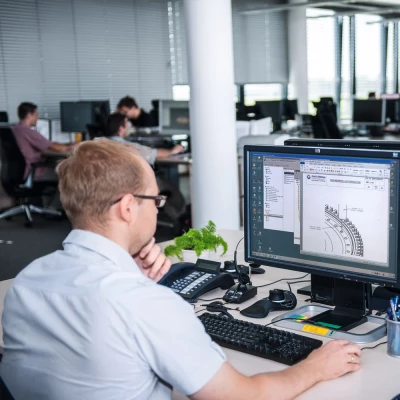

Much like MTU did roughly ten years ago. In the space of just nine months it built the 18,000-square-meter MTU Aero Engines Polska facility right opposite the international airport in Jasionka near Rzeszów and equipped it with the first machines. MTU has invested a total of over 50 million euros in this project. The deputy Polish prime minister and finance minister attended the opening ceremony in May 2009.

MTU Aero Engines Polska

MTU Aero Engines Polska began operations in Poland’s Aviation Valley in April 2009. In the southeast corner of the country just outside of Rzeszów, this special economic zone is home to more than 80 aviation companies with production and research facilities. To the video

“Here in Rzeszów we found a high concentration of aviation expertise and an excellent infrastructure”, says Krzysztof Zuzak. He has been managing director of the site from the very beginning. Over 14,000 students attend the local polytechnic where the proportion of future aviation engineers is especially high. “Rzeszów has a long tradition in aircraft construction,” says Zuzak. “More than 60 percent of our engineers come from the polytechnic here in Rzeszów.” There is a faculty of mechanical Engineering and Aeronautics that offers courses and specializations related to the aviation industry. Dr. Joachim Wulf, head of development at the site from 2009 until some years ago, once said that: “Rzeszów is a very charming university town like Tübingen in Germany.”

MTU started with the development and manufacture of vanes and blades for low-pressure turbines, the assembly of low-pressure turbines and repair of aircraft parts. The advantages of the location, the town and its surroundings, soon became clear. Especially since all three areas of expertise, namely development, production and repair of engine components were brought together under one roof here: a first for MTU.

Expansion is part of MTU’s investment and growth strategy

The initial workforce of 200 grew fast. Four years later, when the decision was made to expand the site, the workforce had grown to 500 – as of 2017, it is more than 750. Moreover, the foresight at the planning stage has now paid off. “We designed the building so that it could be extended for future requirements,” says Zuzak. With the addition of the new buildings, the Jasionka site now covers almost three hectares. Just like the blisk production facility in Munich and the logistics center in Hannover, which were completed at about the same time, the expansion is part of MTU’s investment and growth strategy.

The extension in Rzeszów houses preparatory work for the new Geared Turbofan™ engines as well as projects, which resulted from the upshare in the A320’s V2500 engine program. There, the Polish plant is now responsible for logistics, procurement, design and quality assurance. It also bundles the module assembly activities for various commercial programs. At the moment, the development department is being enlarged. It will offer jobs for 140 engineers in total.

The best of both worlds

At EME Aero, the teams are currently finalizing the details of an ambitious ramp-up plan for the shop. This is a complex matter says Jana Kotlar, the project manager at MTU. “Not only will we have to build a new facility, we also had to implement stable processes in a relatively short timespan.”

At some point this year, employee training will go ahead. And a subsequent simulation phase to test every last detail of the MRO process from order dispatch to final acceptance will take place. “We use the best of both worlds in designing our processes,” says Kotlar. The expansion project comprises more than a dozen subprojects. “In each case, one partner will take the lead, but process interfaces are seamless.”

The joint venture benefits from the considerable expertise accumulated by Lufthansa Technik and MTU in their respective fields. Since 2003, they have been operating a similar 50:50 MRO joint venture in Malaysia. It specializes in the repair of airfoils for low-pressure turbines and high-pressure compressors. “We also know each other well from working together in Germany,” says Kotlar, “for example through mutual support in test runs or piece parts.”

The first PW1000G engine will arrive at the shop for maintenance in 2020. Once the ramp-up has been completed, EME Aero will employ a workforce of 1,000.