aviation

40 years and no end in sight: The V2500 engine celebrates its anniversary

This year, the IAE consortium is celebrating 40 years of its V2500 engine, one of the most successful engine programs ever.

author: Thorsten Rienth | 3 mins reading time published on: 12.10.2023

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

“Forty years ago, there was no such thing as a quick phone call to the U.S. or a video conference with Japan,” says Klaus Diederichs with a smile. Today, the engineer serves on the Executive Board of the Friends of MTU Engine Technology association. The reason his memories are so vivid is because he was one of the first MTU employees to work at the headquarters of the International Aero Engines (IAE) consortium after it was founded in 1983.

Back then, the spirit there in Hartford, in the U.S. state of Connecticut, was one of real optimism. “A joint venture that brought together five nations on three continents to develop and produce a new short- and medium-haul engine: well, that was quite an extraordinary thing,” Diederichs says.

Optimism gives way to disillusionment—but then comes IAE’s breakthrough

Those early years demanded stamina. Certified in 1988, the first V2500-A1 entered service a year later on an Adria Airways Airbus. “My main responsibility was the MTU low-pressure turbine. Much of the focus was on cost issues and delivery capabilities,” Diederichs recalls. It turns out this was a lucky break: on the engine’s other modules, the partner companies’ representatives had to spend most of their time overcoming teething problems.

IAE’s breakthrough only really came in 1991, when United Airlines opted for the V2500 to power its order of 100 new aircraft from the A320 family. A short time later, Lufthansa selected the engine for its new Airbus A321 aircraft. From that point on, the engine became a firm favorite in the aviation world. Since first taking to the skies in 1986, V2500 engines have completed 135 million flights and a good 255 million flight hours; they will log almost 16 million flight hours in the course of 2023. More than 2,300 jets currently use them to take off, fly, and land for over 160 airlines. Every ten seconds, a V2500-powered aircraft takes off somewhere in the world.

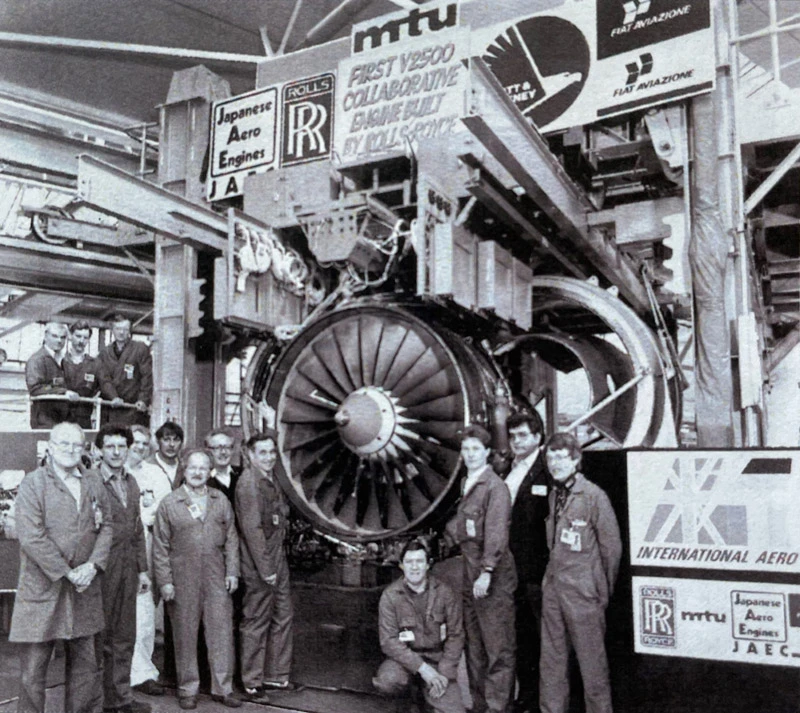

When it all began: The first V2500 engines were tested on shareholders’ test stands in 1986.

Virtually all MTU employees have some connection to the “V”

Without the “V,” as MTU colleagues affectionately abbreviate it among themselves, the company would likely have missed out on much of its growth over the past two decades: with a 16 percent share of the program, MTU is responsible for the development of the low-pressure turbine (LPT), the casing, and the accessories and externals. In addition, the company produces a range of LPT components as well as the casing.

The V2500 is now available in four variants: the A1 and A5 for the Airbus A320; an uprated and downrated A5 for each of the Airbus A321 and the Airbus A319; the D5 for the McDonnell Douglas MD-90; and the E5 for the Embraer C-390 military transporter, which went into large-scale production only a few years ago. And the engine is now in the process of reaching another important milestone: MTU’s Hannover site is currently testing the addition of 10 percent sustainable aviation fuel (SAF), and the engine experts believe that as much as 100 percent is possible.

Shop visits: About 30 percent of the 5,286 engines in service still have their first scheduled shop visit ahead of them.

V2500 Facts

500,000 people fly in V2500-powered aircraft every day.

5,286 V2500 engines are currently in service worldwide.

135 million flights have been carried out with V2500s since the engine’s maiden flight in 1986.

That’s more than 255 million flight hours.

50 percent is the approximate market share of the V2500 in narrowbody aircraft.

Every ten seconds, a V2500-powered aircraft takes off somewhere in the world.

MTU’s component manufacturing operations are mainly concentrated at its sites in Munich and Rzeszów. Maintenance, partly on behalf of IAE and partly directly for airlines, is performed at MTU’s Hannover, Vancouver, and Zhuhai locations. Nova Pazova in Serbia and Kota Damansara in Malaysia are involved in parts repair. And of course, MTU Maintenance Lease Services also has the V2500 in its portfolio. MTU employees who have never had anything to do with this engine are thin on the ground.

And yet, in IAE’s 40th anniversary year, the program has only just reached the peak of its commercial viability. “Between 2014 and 2017 in particular, IAE was delivering up to 500 engines a year,” says Reiner Wenig, Head of Business and Operations for the V2500 LPT. “That means the engine fleet is still comparatively young: of the nearly 5,300 engines currently in service, around 30 percent haven’t even had their first shop visit yet, which is due after seven years of operation.” At the same time, a great number of older engines are still in use. “So the demand for spare parts remains high,” Wenig says.

Having different companies and cultures come together as IAE back in the early 1980s could have proven to be a weakness. But it might also be the secret of IAE’s success. One thing is clear: no one will ever be able to deny that IAE produced one of the most successful engines in the history of commercial aviation.

V2500: The V2500 is now available in four variants: the A1 and A5 for the Airbus A320, the D5 for the McDonnell Douglas MD-90, and the E5 for the Embraer C-390 military transporter.