good-to-know

The Airbus A380 – the world’s largest passenger aircraft

The Airbus A380 continues to inspire aviation today and remains unsurpassed in many respects. It also has a role to play on the way to climate-neutral aviation.

author: Isabel Henrich | 4 mins reading time updated on: 21.08.2025

author:

Isabel Henrich

studied political science and communications. At MTU, she coordinates the editorial process of AEROREPORT and is responsible for the conception and development of its content.

- Boeing 747: Queen of the Skies

- The Boeing 737: How a simple jet revolutionized aviation

- Airbus A400M – modern military transporter and all-around talent

- Airbus A220 – The innovative medium-haul jet from Canada

- Boeing 777X – the largest twin-engine jet in the world

- Airbus A321XLR: A new chapter for aviation

- The Airbus A380 – the world’s largest passenger aircraft

- Airbus A319 – a small aircraft for a wide range of tasks

- Airbus A320 – a medium-haul bestseller for almost 40 years

For a passenger aircraft, it had a short but glorious run: the Airbus A380 debuted in 2007, and the last one left its production facility in Hamburg-Finkenwerder just 14 years later in December 2021. The aircraft was intended to cover the expected high volume of flights when it entered service, but demand for the four-engine aircraft fell short of expectations. In 2011, Boeing launched its 787 Dreamliner—much smaller, much more efficient, and an economically viable way of serving nonstop long-haul routes out of secondary airports. Airbus countered with the A350. Suddenly, people could take a twinjet from, say, Düsseldorf and fly directly to destinations like Tokyo or Hong Kong. The pandemic and the resulting slump in air traffic exiled the giant A380 to parking lots in deserts; common wisdom said it was doomed. But the common wisdom was wrong: in fall 2021, the number of people traveling rose so sharply that several airlines pressed their A380 fleets back into service as the ideal solution to an urgent problem. The result was an unexpected renaissance for the superjumbo. And its story doesn’t seem to be over yet: the new British airline Global Airlines plans to operate a fleet made up solely of A380s that are currently not in service. The “gentle giant” continues to delight passengers and aviation enthusiasts to this day with its size and comfort.

The Airbus A380: Facts and figures

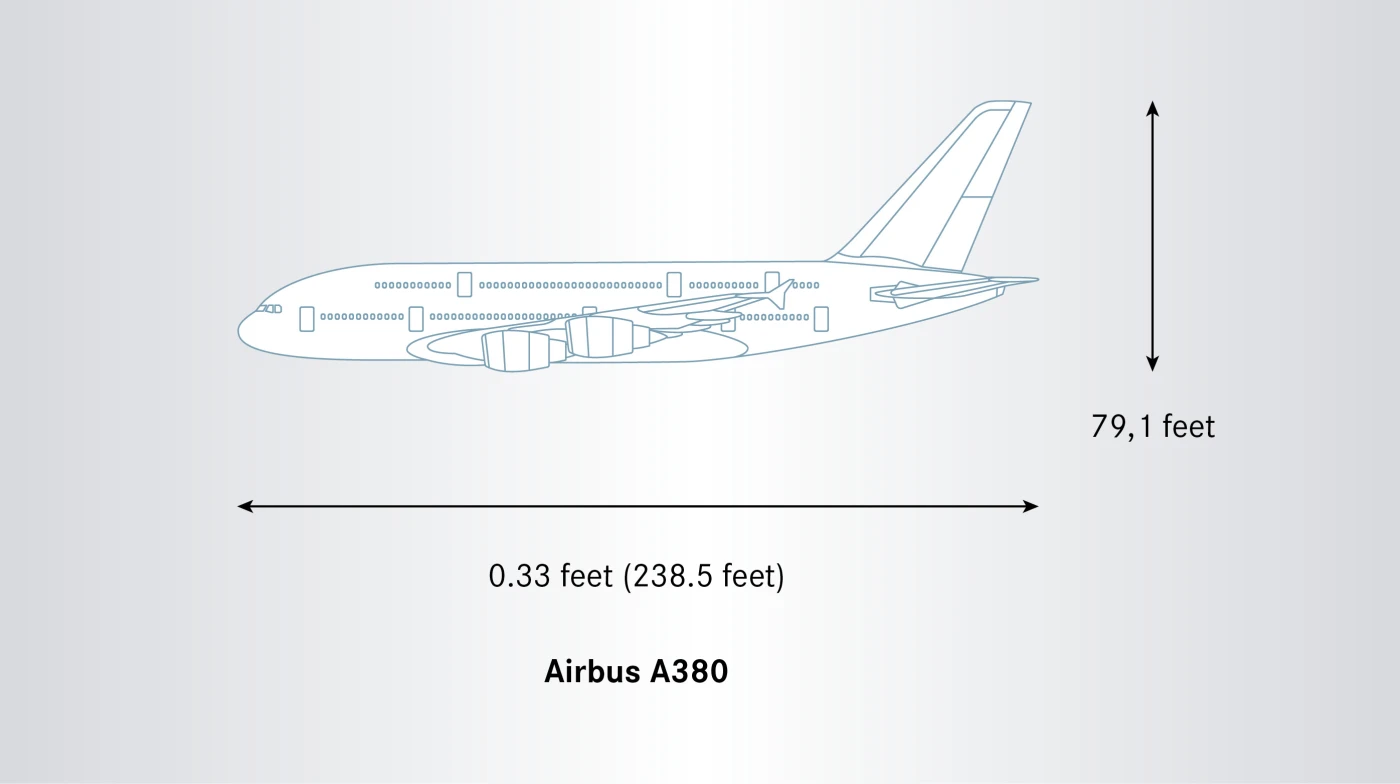

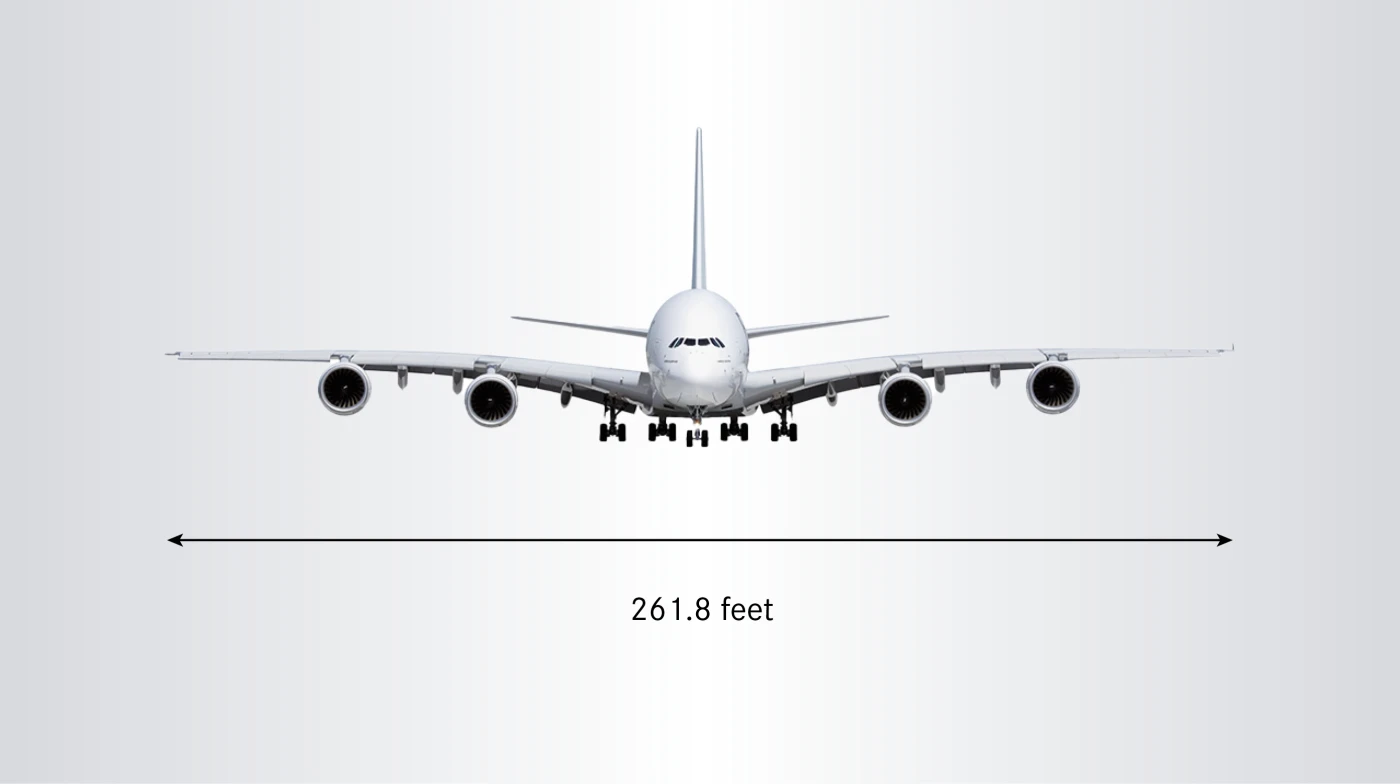

- As the world’s largest passenger aircraft, the Airbus A380 features impressive dimensions: a wingspan of 261.8 feet, a length of 238.5 feet, and a height of 79.1 feet. This makes it as long as two blue whales and as tall as five giraffes. During takeoff, the wings flex upward more than four meters.

-

The four-engine widebody aircraft is also the first in the world with two full-length passenger decks. These offer a total area of 5,920 square feet—roughly the same as three tennis courts. Its double-decker design offers space for 545 passengers in a standard four-class configuration, making it particularly attractive for busy long-haul routes. In a single-class configuration, there would even be space for 853 passengers.

-

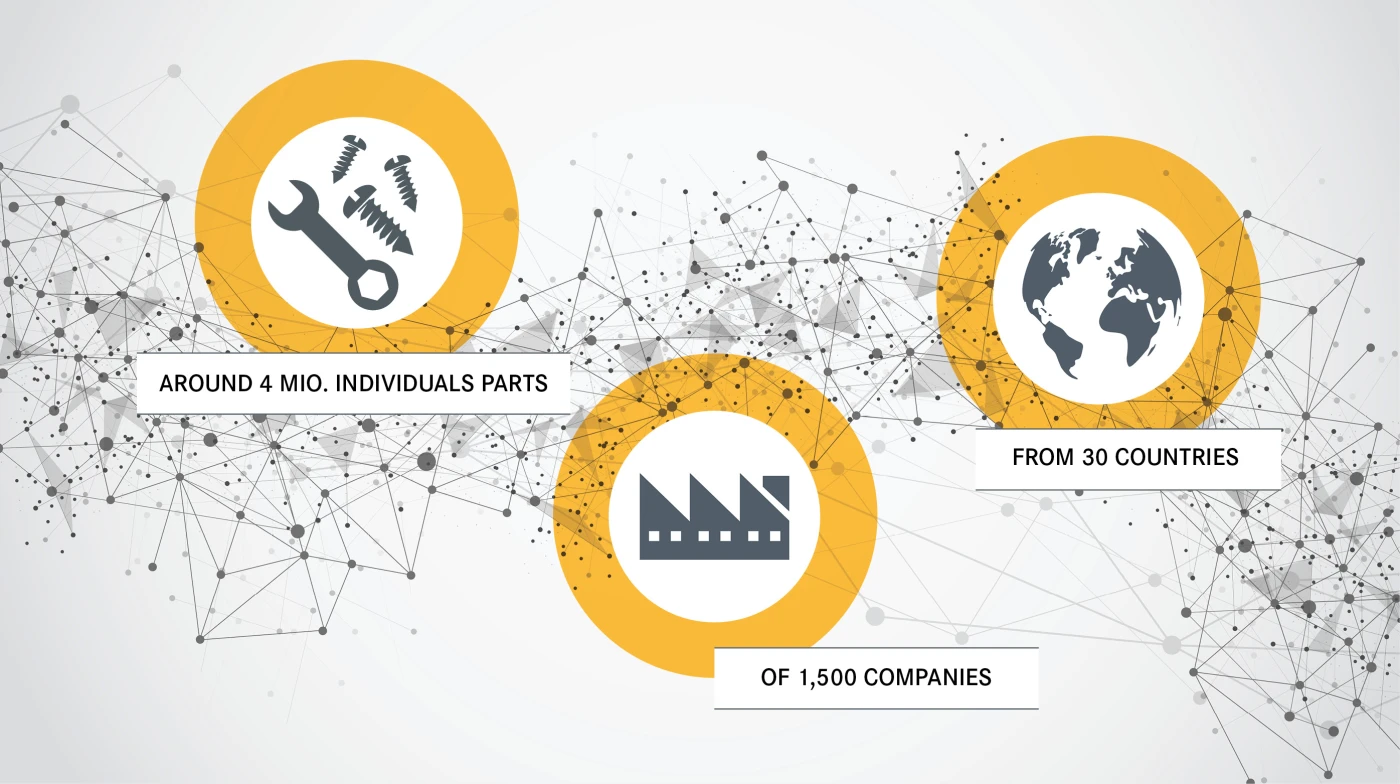

Each A380 consists of around four million individual parts, which are manufactured by 1,500 companies in 30 countries.

-

The aircraft has 220 windows and 16 doors.

-

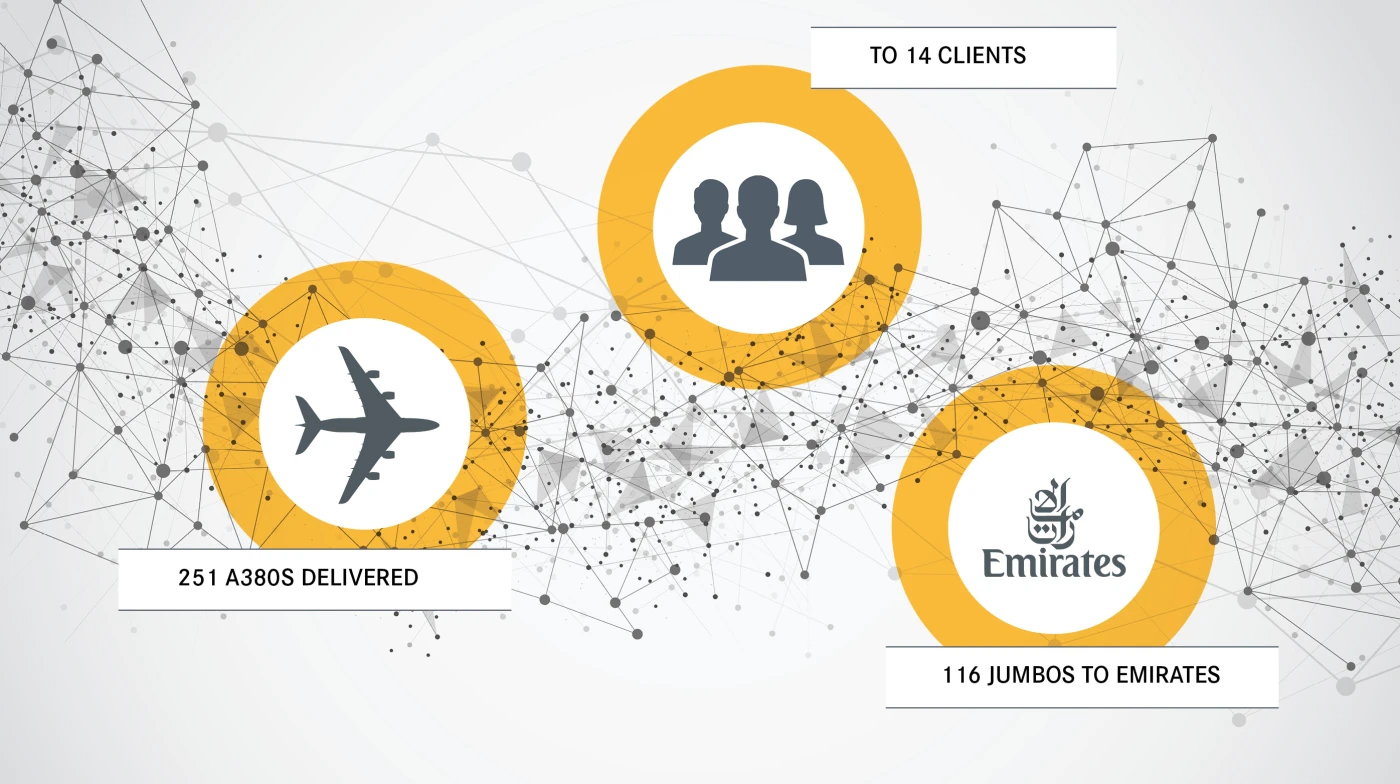

To date, 251 A380s have been delivered to 14 customers. The largest customer is Emirates, which operates 116 of the jumbo jets.

-

With a range of up to 9,320 miles at full passenger capacity, the A380 is ideal for some of the longest nonstop flights in the world.

-

Since entering service, the A380 has completed more than 800,000 flights and carried more than 300 million passengers.

©Airbus SAS 2022 Alexandre Doumenjou

©Airbus SAS 2022 Alexandre Doumenjou

©Airbus SAS 2022 Alexandre Doumenjou

ZEROe: The demonstrator is the Airbus A380 MSN1.

-

In the A380, Airbus introduced its Brake-to-Vacate technology, which enables flight crews to control their approach and landing more efficiently by selecting the optimum runway exit in advance. As a result, runway occupancy can be reduced by up to 30 percent, significantly increasing the number of aircraft that can be handled at airports around the world. This technology has also been integrated into the A350 aircraft.

-

Airbus has already carried out several test flights with the A380 and 100 percent sustainable aviation fuel. For its ZEROe demonstrator program, the company plans to test hydrogen technologies over the next few years. Serving as demonstrator is the Airbus A380 MSN1, the very first A380 to roll off the production line.

-

The A380 is powered by four Engine Alliance GP7000 engines in the 70,000–81,500 lbf thrust range—roughly equivalent to the propulsive power of around 2,500 cars. Combined with an advanced wing and landing gear design, the A380 is significantly quieter than other large commercial aircraft.

Airbus A380

Airbus A380

- Type:

- Four-engine widebody aircraft

- Manufacturer / origin:

- Airbus, Toulouse, France

- Maiden flight:

- April 27, 2005

- Entry into service:

- October 25, 2007 with Singapore Airlines

- Produced:

- 2003-2021

- Number built:

- 254 units

- Length:

- 72.72 meters

- Wingspan:

- 79.75 meters

- Range:

- 14,800 kilometers

- Cruising speed:

- 903 km/h

- Seats (typical / maximum):

- 500/853 passengers

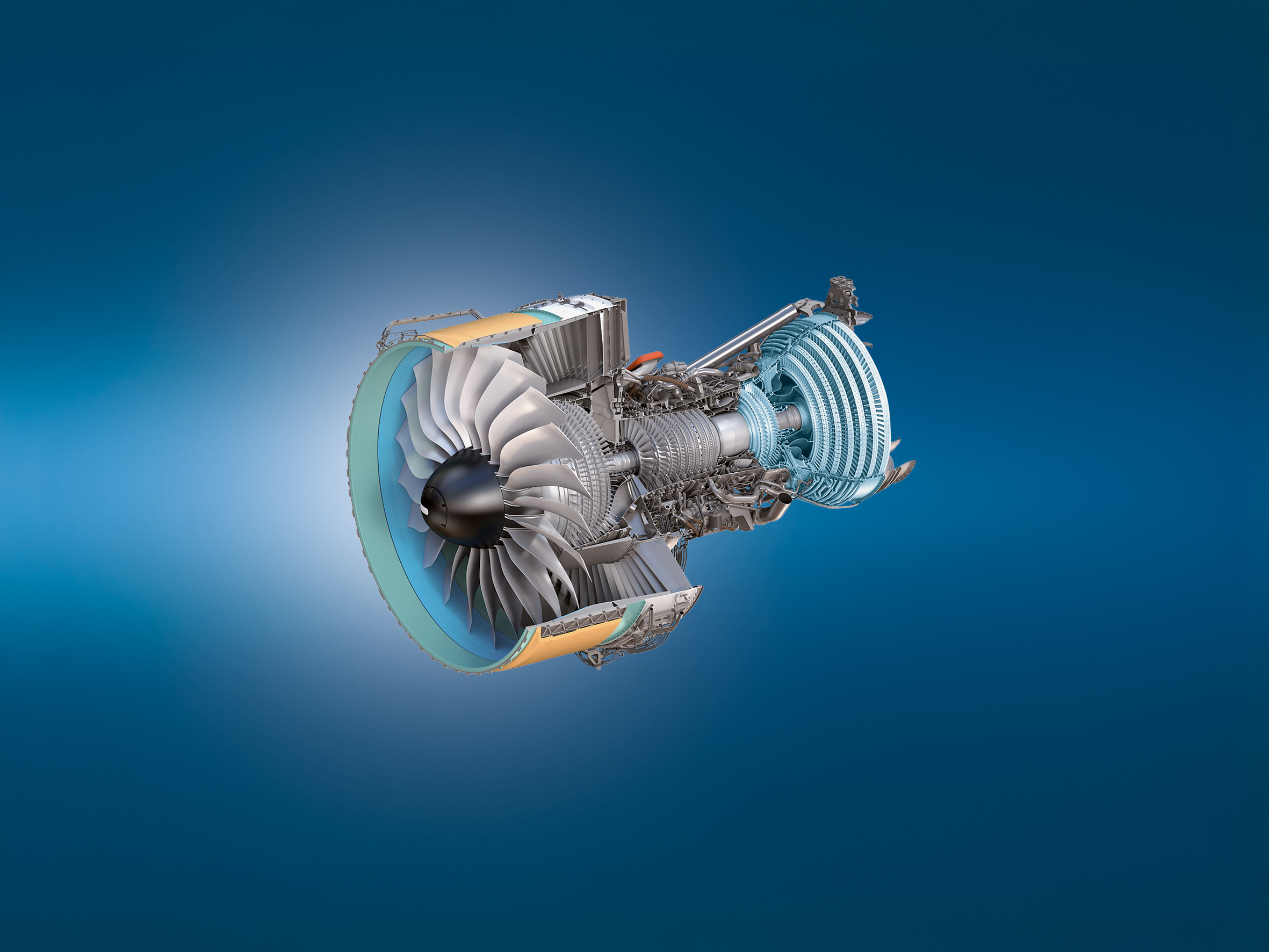

The GP7000 for the A380

Developed, manufactured, and sold by the Engine Alliance, the GP7000 is characterized by low fuel consumption, low weight, and reduced noise emissions.

The GP7000 brought two worlds together: GE was responsible for the high-pressure turbine and high-pressure compressor, which borrowed significantly from the GE90 that powered the Boeing 777, but with certain components adjusted for the lower thrust requirements of the A380. Pratt & Whitney followed suit, capitalizing on its own product for the 777, the PW4000, for the low-pressure turbine and low-pressure compressor.

However, even though the Engine Alliance is a joint venture between GE Aerospace and Pratt & Whitney, this doesn’t mean that those two companies manufacture the entire engine themselves. On the contrary, MTU Aero Engines secured most of the remaining program share. Germany’s leading engine manufacturer has a 22.5 percent stake in the GP7000 and is responsible for developing, manufacturing, and assembling the entire low-pressure turbine and the turbine center frame, as well as manufacturing the blades and disks for the high-pressure turbine. In addition, maintenance of the low-pressure turbine takes place at MTU in Munich.

The GP7000 program is yet another milestone in MTU history. It gave the Munich team a foothold in the next generation of widebody engines: the contract to develop and manufacture the turbine center frame for the GP7000 was followed by corresponding work on the GEnx (787, 747-8) and the GE9X (777-8X and 777-9X). And also MTU Maintenance benefited from contracts and gained valuable expertise from maintaining widebody engines.

GP7000

GP7000

- Type:

- Two-shaft turbofan engine

- Max. thrust:

- 81,500 lbf

- Pressure ratio:

- 43.9:1

- Fan diameter:

- 9.5 ft

- MTU competencies:

- Development and manufacture of low-pressure turbine and turbine center frame and manufacture of high-pressure turbine components. Maintenance of the low-pressure turbine at MTU Aero Engines in Munich.

„We were impressed right from takeoff: the A380 was astonishingly quiet inside, even during climb.“

Aviation journalist Andreas Spaeth recalls

The production of the A380 had been delayed for years due to various issues among Airbus partners. As a result, my very first flight on the aircraft didn’t take place until February 8, 2007 – eight months before regular passenger service began. It was the first flight ever with external guests, a demonstration flight to and from Toulouse aboard the pre-series aircraft with serial number 007, which was later delivered to Emirates. This particular aircraft was the only one in the test phase equipped with a fully fitted passenger cabin – 519 seats across three classes.

We were impressed right from takeoff: the A380 was astonishingly quiet inside, even during climb. Despite encountering strong crosswinds and wind shear from a thunderstorm front, the giant aircraft remained remarkably stable. The wingtips briefly flexed up and down, but the flight quickly smoothed out. “In a small A320, that would have been a bumpy ride,” explained test pilot Wolfgang Absmeier.

The onboard computers handled the turbulence almost magically, automatically adjusting the wing flaps without any pilot intervention. We test passengers were euphoric when we landed after two hours and one minute – whether it was the generous flow of champagne or the aircraft itself that caused the excitement, remains uncertain.