good-to-know

Airbus A319 – a small aircraft for a wide range of tasks

The small Airbus A319 successfully rounds off the lower end of the A320 family and has proven itself at demanding airports.

author: Andreas Spaeth | 7 mins reading time published on: 06.11.2025

author:

Andreas Spaeth

has been traveling the world as a freelance aviation journalist for over 25 years, visiting and writing about airlines and airports. He is frequently invited to appear on radio and TV programs to discuss current events in the sector.

©Airbus 2019 - photo by P. MASCLET / master films

- Boeing 747: Queen of the Skies

- The Boeing 737: How a simple jet revolutionized aviation

- Airbus A400M – modern military transporter and all-around talent

- Airbus A220 – The innovative medium-haul jet from Canada

- Boeing 777X – the largest twin-engine jet in the world

- Airbus A321XLR: A new chapter for aviation

- The Airbus A380 – the world’s largest passenger aircraft

- Airbus A319 – a small aircraft for a wide range of tasks

- Airbus A320 – a medium-haul bestseller for almost 40 years

For an aircraft model to succeed in the marketplace, it needs a balanced family—and for the Airbus A320 family, the A319 plays a key role in the lower capacity segment. This variant is 3.73 meters shorter than the basic A320 model, which means that the A319’s wingspan is wider than its fuselage is long. With the tank capacity unchanged despite the lower weight and reduced number of passengers, the A319 has a greater range than its bigger sister.

Until the temporary introduction of the even shorter A318 in 2001, production of which was discontinued in 2013, the A319 was the smallest model in the Airbus range, as it is today. The A319 is especially popular with major U.S. airlines. In Europe, it formed the backbone of easyJet’s fleet for many years, with the airline operating a total of 172 aircraft of this type. Germanwings—now Eurowings—also operated 52 A319s, and at times Lufthansa has had 41 A319s in its fleet.

For Germany, and for Hamburg in particular, the A319 marked a milestone: Before the 1990s, neither Hamburg-Finkenwerder nor any other German site performed final assembly for passenger aircraft. This changed with the expansion of the A320 family. Since the start of production in 1994, the A319—like the A321 before it—has been manufactured exclusively in Hamburg. It was only later that Airbus relocated parts of its production to other sites, including Toulouse (France), Tianjin (China), and Mobile (USA).

©Airbus

©Airbus

The ACJneo Family, featuring the ACJ319neo and ACJ320neo, combines next-generation engines for superior efficiency with spacious, customizable cabins for unparalleled comfort.

©Airbus Operations GmbH 2022

©Airbus Operations GmbH 2022

Efficiency in flight: The so-called sharklets at the wing tips reduce drag and save fuel.

©Airbus

©Airbus Operations GmbH 2022

Airbus A319 – Facts, figures, dates

-

All models in the A320 family, the A319 included, can be flown with the same type rating. This means pilots can easily switch between the different models in the family, which represents a considerable logistical advantage for airlines.

-

A particular highlight in the history of the A319 occurred in January 1997: During its delivery flight, one aircraft managed to fly from Hamburg to Winnipeg (6,645 kilometers) in just nine hours and five minutes—a record for this aircraft type.

-

In the long-haul version, the A319LR, the model’s additional tanks give it a range of up to 8,300 kilometers. The ACJ319 business jet version, equipped with additional fuel tanks and designed for just eight passengers, can even fly an impressive 11,100 kilometers nonstop.

-

A modernized version, the A319neo, completed its maiden flight in Hamburg on May 31, 2017. It was fitted with new, more efficient engines, aerodynamic improvements such as Sharklets on the wingtips, and a revised cabin design. However, commercial success remained elusive: By May 2025, only 57 orders had been received—a tiny number compared to the more popular, bigger neo variants.

-

The A319 also opens up new prospects in air rescue and emergency management: The Canadian company Neptune Aviation is planning to convert 10–15 decommissioned A319ceo aircraft into state-of-the-art firefighting aircraft by 2027. With the ability to transport and drop up to 17 metric tons of water or retardant, these will replace the company’s smaller BAe 146 tankers.

Airbus A319

Airbus A319

- Type:

- Twin-engine narrowbody aircraft

- Manufacturer/origin:

- Airbus – Toulouse, France

- Maiden flight:

- August 25, 1995

- Entry into service:

- April 25, 1996

- Produced:

- 1994–today (A319neo)

- Number built:

- 1,543 (up to the end of 2024, of which 57 A319neo)

- Length:

- 33.84 meters

- Wingspan:

- 35.80 meters

- Range:

- 6,940 kilometers

- Cruising speed:

- Mach 0.82 (871 km/h)

- Seats (typical/maximum):

- 134/150 or 160

You may also be interested in following content

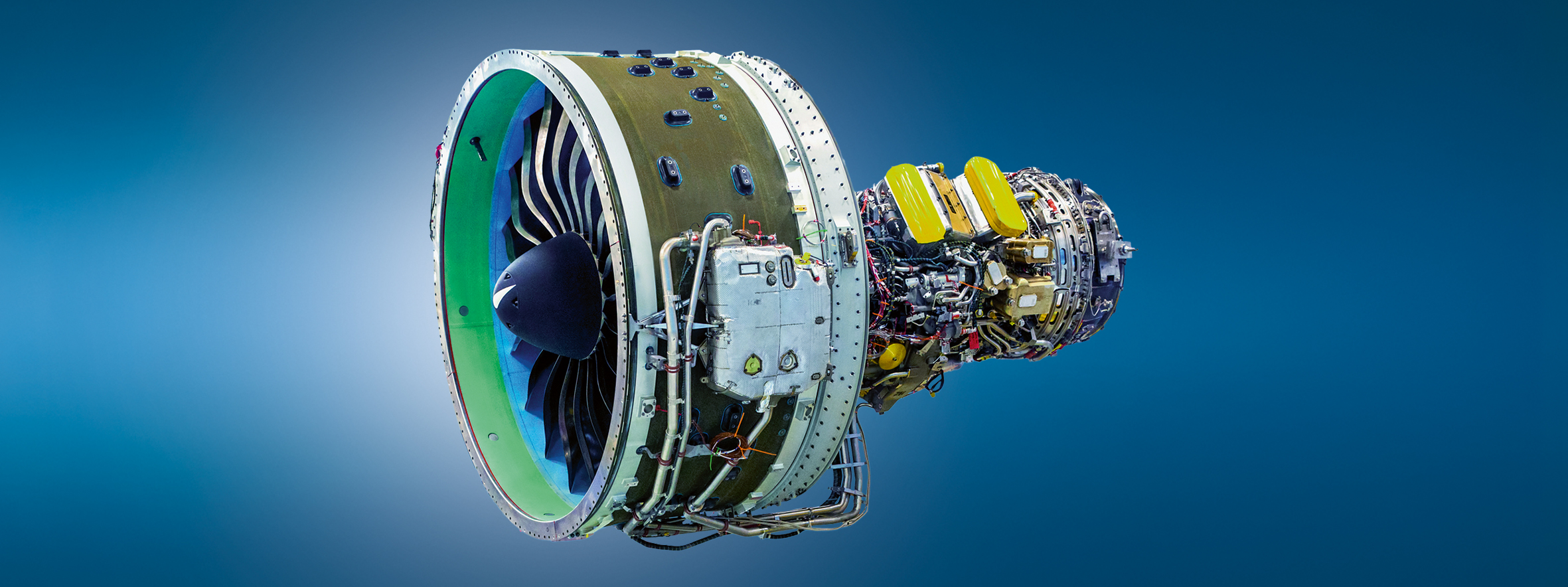

GTF™ Engine Family

The Pratt & Whitney GTF™ engine family powers next-generation commercial aircraft.

The A319’s engines

The original version of the Airbus A319 (ceo, or “current engine option”) was offered with two engine options: the CFM56-5B from CFM International and the V2500-A5 from International Aero Engines. Both are two-shaft turbofan engines in the medium thrust class and are characterized by high reliability, low specific fuel consumption, and broad global availability.

With the A319neo variant (“new engine option”), as with the larger members of the family, Airbus opted for new engines with improved efficiency. The choice is between the LEAP-1A from CFM International and the PW1100G-JM from the Pratt & Whitney GTFTM engine family. MTU, with a program share of 18 percent in the PW1100G-JM, is responsible for components including the high-speed low-pressure turbine and the first four stages of the high-pressure compressor. It also carries out the final assembly of one-third of production GTFs at its Munich site. Maintenance takes place at MTU Maintenance Hannover, MTU Maintenance Zhuhai, EME Aero, and MTU in Munich.

PW1100G-JM

PW1100G-JM

- Type:

- two-shaft turbofan engine

- Thrust (lbs):

- 24.4 -33 k

- Bypass Ratio:

- 12.5:1

- Fan diameter:

- 6.7 ft

- MTU competencies:

- Development and manufacture of various stages of the high-pressure compressor, of the high-speed low-pressure turbine and brush seals in all applications. 1/3 of the final assembly of the PW1100G-JM series engines takes place at MTU Aero Engines in Munich. Maintenance at MTU Maintenance Hannover, MTU Maintenance Zhuhai, EME Aero and MTU in Munich.

MTU Maintenance Zhuhai began maintaining the LEAP-1A in 2021. In addition, through MTU Maintenance Lease Services B.V. in Amsterdam, MTU offers a range of engine leasing options. As a premium MRO partner, MTU Maintenance Fort Worth will also be responsible for the complete maintenance of LEAP engines in the future. The LEAP engine family is characterized by a 15 percent improvement in fuel consumption compared to previous versions.

LEAP-1A

LEAP-1A

©Antonio Gomez/Safran

- Type:

- two-shaft turbofan engine

- Max. thrust:

- 35,000 lbf

- Bypass Ratio:

- 11:1

- Height:

- 7.8 ft

- MTU competencies:

- Maintenance by MTU Maintenance Zhuhai and on-site service activities. MTU Maintenance Fort Worth will be responsible for the complete maintenance of LEAP engines in the future.

The A319 was here to conduct flight tests in the extremely thin high-altitude air; as guests, we could observe the tests from the airport.

Aviation journalist

Aviation journalist Andreas Spaeth recalls

On March 14, 1996, I had the opportunity to take part in a very special flight: As part of the A319’s flight test program prior to certification, we took off from Santiago de Chile on board a preproduction model for a spectacular crossing of the Andes. The route took us in a tight loop right around the summit of Aconcagua—the highest mountain in South America at almost 7,000 meters. A literally breathtaking experience.

Our destination was La Paz in Bolivia—at 4,061 meters, one of the highest airports in the world. The A319 was here to conduct flight tests in the extremely thin high-altitude air; as guests, we could observe the tests from the airport. Two days later, on the return flight, we set a remarkable record that may still stand today: From La Paz we first flew in five hours to Guadeloupe in the Caribbean to refuel, before then flying nonstop in seven hours back to Toulouse. There were no more than ten people on board, so most of the cabin was unoccupied. Out came my sleeping bag—what an occasion!

At the start of 2009, I had another impressive A319 experience with Drukair, the national airline of Bhutan. The country’s only major airport, Paro, is considered one of the most difficult approaches in the world. Surrounded by Himalayan peaks that are 4,000 to 6,000 meters high, the approach is possible only with specially trained pilots and powerful aircraft. Due to dangerous winds, the airport closes daily at 12 noon. Drukair relies on specially configured A319s with engines whose thrust corresponds to that of the larger A321. Should an engine fail during takeoff in Paro, the aircraft could turn around in the narrow valley if necessary and land safely—or simply climb over the surrounding six-thousand-meter peaks without any problems.

The flight from Delhi via Kathmandu to Paro offers a breathtaking panorama: Mount Everest is just one of many eight-thousanders that together form a mighty chain of towering peaks. The A319 is ideally suited to these kinds of demanding missions because it combines compact size with powerful thrust.