good-to-know

Airbus A320 – a medium-haul bestseller for almost 40 years

From a ridiculed project to a global bestseller: The Airbus A320 stands for European engineering, technological innovation, and an unparalleled success story.

author: Andreas Spaeth | 7 mins reading time published on: 13.11.2025

author:

Andreas Spaeth

has been traveling the world as a freelance aviation journalist for over 25 years, visiting and writing about airlines and airports. He is frequently invited to appear on radio and TV programs to discuss current events in the sector.

- Boeing 747: Queen of the Skies

- The Boeing 737: How a simple jet revolutionized aviation

- Airbus A400M – modern military transporter and all-around talent

- Airbus A220 – The innovative medium-haul jet from Canada

- Boeing 777X – the largest twin-engine jet in the world

- Airbus A321XLR: A new chapter for aviation

- The Airbus A380 – the world’s largest passenger aircraft

- Airbus A319 – a small aircraft for a wide range of tasks

- Airbus A320 – a medium-haul bestseller for almost 40 years

Worldwide, the Airbus A320 and its sister models are currently the most flown commercial aircraft. Back in the 1980s, it was hard to imagine that a European medium-haul aircraft would take on this mantle. Even optimistic forecasts expected sales of just a few hundred or at best a thousand units. But Airbus dared to do something completely new: It built a modularly expandable, technologically pioneering aircraft with electronic controls, a digital cockpit, and efficient aerodynamics.

The public soon gave the A320 the nickname “Atari plane” after the popular home computer of the time, which for many people marked their entry into the digital world. Indeed, the aircraft was far ahead of its time: A small control lever to the side of the cockpit—the sidestick—replaced the traditional control stick and could be operated without effort. And instead of using mechanical cables, the fly-by-wire system controlled the aircraft purely electronically. Supported by on-board computers designed to automatically prevent critical flight conditions, the A320’s cockpit became the blueprint for all later Airbus models. This boosted safety and at the same time symbolized a paradigm shift in aircraft design.

Not only did the A320 family become the mainstay of global air traffic, but it also gave Airbus long-term market leadership in commercial aircraft manufacturing. Insatiable demand, especially for the modernized A320neo version, has secured the company a strong position to this day, giving it scope for new investments.

©Airbus - Master Films - Hervé Goussé

©Airbus - Master Films - Hervé Goussé

©Airbus - Master Films - Hervé Goussé

A320 cockpit featuring the side-mounted sidestick and fully electronic fly-by-wire control system, enabling precise handling and significantly enhancing operational safety.

Airbus A320 – Facts, figures, dates

-

France was the driving force behind the launch of the A320 program. Air France ordered the first 25 aircraft in June 1981 and received its first batch in spring 1988.

-

On February 14, 1987, the British heir to the throne, Prince Charles (now King Charles III), and his then wife, Princess Diana, ceremonially christened the new Airbus model in Toulouse as the A320. At this point, 437 orders had already been placed.

-

The maiden flight was originally scheduled for Saturday, February 21, 1987. As several important rugby matches were taking place that day, Airbus postponed the flight so it could be sure of the media’s full attention. Type certification followed one year later, on February 26, 1988.

-

The A320 was the first commercial aircraft to be fitted with wingtip fences—small attachments on the wingtips that reduce air turbulence and lower fuel consumption. Starting in 2012, all new A320s were fitted with the larger Sharklets, which save at least 3.5 percent fuel on longer routes.

-

Due to high demand, the A320 is now manufactured at four locations: at the Airbus headquarters in Toulouse (from the outset), in Hamburg-Finkenwerder and Tianjin, China (both since 2008), and in Mobile, USA (since 2015).

-

The modernized A320neo version has been flying with PW1100G-JM engines and the CFM LEAP engine since 2016. Production of the original A320ceo version was discontinued in 2021.

-

Since its maiden flight in 1988, the A320 has become the basis for an entire family of aircraft. In addition to the stretched A321, this includes the shortened A319 and the particularly compact A318. In March 2025, there were 11,025 A320 family aircraft in service with over 375 operators worldwide.

-

The best-known A320 is now in the Sullenberger Aviation Museum in Charlotte, North Carolina—with all its scars on display: In January 2009, Chesley “Sully” Sullenberger spectacularly ditched this very aircraft (registration N106US) on the Hudson River in New York after a bird strike caused engine failure.

-

With 6,340 units active (as of March 2025), the A320 is in such widespread use that, on average, an aircraft of this type takes off somewhere in the world every two seconds.

Airbus A320

Airbus A320

- Type:

- Twin-engine narrowbody aircraft

- Manufacturer/origin:

- Airbus – Toulouse, France

- Maiden flight:

- February 22, 1987

- Entry into service:

- April 8, 1988

- Produced:

- 1987–today

- Number built:

- 6,754 (A320ceo and neo delivered up to April 2025)

- Length:

- 37.57 meters

- Wingspan:

- 35.80 meters

- Range:

- 6,500 kilometers (A320neo)

- Cruising speed:

- 833 km/h

- Seats (typical/maximum):

- 164/186

You may also be interested in following content

GTF™ Engine Family

The Pratt & Whitney GTF™ engine family powers next-generation commercial aircraft.

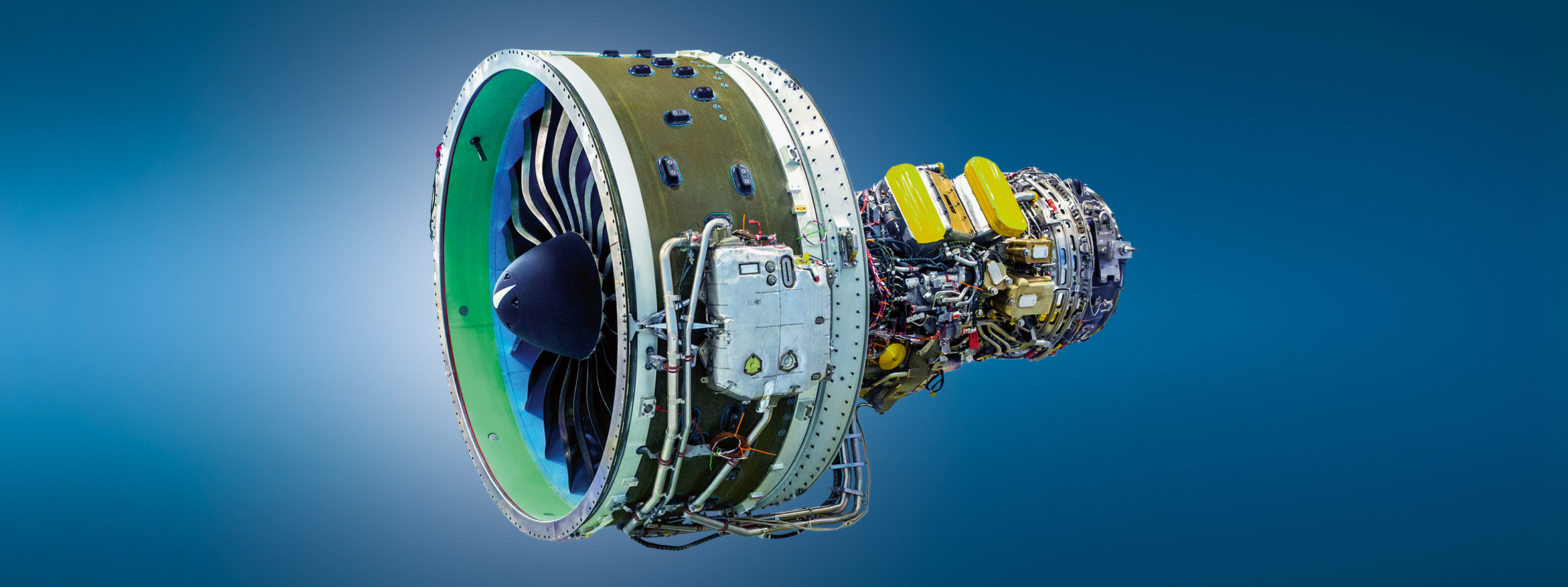

The A320’s engines

Originally, the Airbus A320 was offered with two engine options: the CFM56 from CFM International and the V2500 from International Aero Engines. Both are among the most successful and widely used engine types in this class.

With the A320neo variant (“new engine option”), and with the larger members of the family, Airbus opted for new engines with improved efficiency. The choice is between the LEAP-1A from CFM International and the PW1100G-JM from the Pratt & Whitney GTFTM engine family. MTU, with a program share of 18 percent in the PW100G-JM, is responsible for components including the high-speed low-pressure turbine and the first four stages of the high-pressure compressor. It also carries out the final assembly of one-third of production GTFs at its Munich site. Maintenance takes place at MTU Maintenance Hannover, MTU Maintenance Zhuhai, EME Aero, and MTU in Munich.

PW1100G-JM

PW1100G-JM

- Type:

- two-shaft turbofan engine

- Thrust (lbs):

- 24.4 -33 k

- Bypass Ratio:

- 12.5:1

- Fan diameter:

- 6.7 ft

- MTU competencies:

- Development and manufacture of various stages of the high-pressure compressor, of the high-speed low-pressure turbine and brush seals in all applications. 1/3 of the final assembly of the PW1100G-JM series engines takes place at MTU Aero Engines in Munich. Maintenance at MTU Maintenance Hannover, MTU Maintenance Zhuhai, EME Aero and MTU in Munich.

MTU Maintenance Zhuhai began maintaining the LEAP-1A in 2021. In addition, through MTU Maintenance Lease Services B.V. in Amsterdam, MTU offers a range of engine leasing options. As a premium MRO partner, MTU Maintenance Fort Worth will also be responsible for the complete maintenance of LEAP engines in the future. The LEAP engine family is characterized by a 15 percent improvement in fuel consumption compared to previous versions.

LEAP-1A

LEAP-1A

©Antonio Gomez/Safran

- Type:

- two-shaft turbofan engine

- Max. thrust:

- 35,000 lbf

- Bypass Ratio:

- 11:1

- Height:

- 7.8 ft

- MTU competencies:

- Maintenance by MTU Maintenance Zhuhai and on-site service activities. MTU Maintenance Fort Worth will be responsible for the complete maintenance of LEAP engines in the future.

What really made an impression on me was a visit to the cockpit, where the chief pilot showed off the sidestick under the cockpit window: a narrow control lever that took the place of the usual control stick.

Aviation journalist Andreas Spaeth recalls

It was a special moment, and it must have been spring of 1987. As a young journalist, I was attending a press event on-site at MBB (Messerschmitt-Bölkow-Blohm), the German Airbus partner at the time, in Hamburg-Finkenwerder. We were there to witness the first ever landing of an A320—the prototype, the first test aircraft—in Hamburg. The atmosphere was expectant: Much was still secret, but it was clear to everyone that this program represented an enormous challenge for Airbus. Until then, all that had been built in Hamburg were parts of the fuselage for the A300 and A310.

Just over a year later, in May 1988, Air France flew a brand new A320—the first to be delivered—to Hamburg to present it to the press. At the time, I was an intern at the local editorial office of a large daily newspaper, and I accompanied my colleagues to the event. What really made an impression on me was a visit to the cockpit, where the chief pilot showed off the sidestick under the cockpit window: a narrow control lever that took the place of the usual control stick. By the standards of the time, this was revolutionary.