aviation

Tailored engine solutions for the Middle East

An ambitious and challenging aviation industry expects customized services. Engine expert MTU is more than happy to provide them.

02.2019 | author: Victoria Nicholls | 5 mins reading time

author:

Victoria Nicholls

is a specialist for aftermarket topics such as engine MRO, leasing and asset management, as well as international market trends. The British-born editor lives in Berlin and works for MTU’s corporate communications in Hannover and Ludwigsfelde.

The Middle East is home to the world’s tallest building, biggest mall and numerous construction projects such as the Jubail II, the world’s largest civil engineering project. In fact, when it comes to mega projects, the Middle East practically invented the term.

The past year has been challenging for the region in terms of aviation: in 2018, seat growth slowed to only two percent among the “Gulf Three”, the mega carriers Emirates, Etihad and Qatar, according to market intelligence provider CAPA. Still, the region is the most ambitious in the world. CAPA reports that although the world’s smallest aviation region, with only 1,650 aircraft in service as of beginning January 2019, the Middle East has the highest orders to fleet-in-service ratio worldwide. Orders from the region currently comprise 1,509 aircraft.

Regional presence

“This is a key region for MTU Maintenance both now and in the future and we support our customers with solutions across the lifecycle–from phase-in to phase-out,” says Sami Ben-Kraiem, Vice President Marketing & Sales, Middle East & Southeast Asia, MTU Maintenance. “We have over 20 customers in the region and are planning to open an MTU office in the Middle East in the very near future to reinforce our customer proximity.”

Dedicated solutions

“Engine trend monitoring has really proven itself in the Middle Eastern market,” says Ben-Kraiem. “We’re seeing much more stable on-wing times with customers using our independent service. And there is the added benefit that multiple engines within a single fleet can be incorporated, such as GE90, CFM56 and V2500. This, in combination with our expertise as an experienced MRO, means we can uniquely support our customers and get the best out of their entire fleets.”

These services are complemented by repairs specifically tailored to harsh environments, such as CMAS (calcium-magnesium-aluminum silicates) Resistant Thermal Barrier Coating and ERCOateco (erosion-resistant coating for HPC airfoils), which reduces scrap rates, improves the durability of the hardware and reduces the SFC (fuel consumption) of the engines. “Such repairs are a very effective way to help operators combat high material costs and considerably improve engine on-wing times,” says Ben-Kraiem.

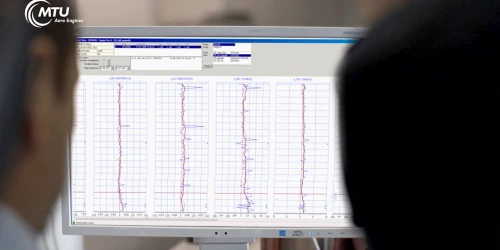

Engine Trend Monitoring

The engine early warning system monitors all key parameters during a flight. It detects even the slightest issues, which can then be fixed before they develop into anything more serious. To the video

MTU Maintenance is also seeing great interest in leasing solutions, in particular for dedicated support in harsh environments. In fact, some of MTUs customers have even managed reduce their own spare level requirement to zero thanks to MTU’s support as their long-term MRO provider, according to Ben-Kraiem. “And that is in a region where 10 percent spares are highly recommended,” he adds.

“With reliable MRO solutions, a unique ETM tool, high-tech repairs and leasing support, MTU Maintenance is ideally placed to serve airlines and lessors from the Middle East,” Ben-Kraiem summarizes. “We’re seeing a marked trend towards fleet management, and as the engine experts in this field, MTU is excited to help its customers in the region in this regard.”