good-to-know

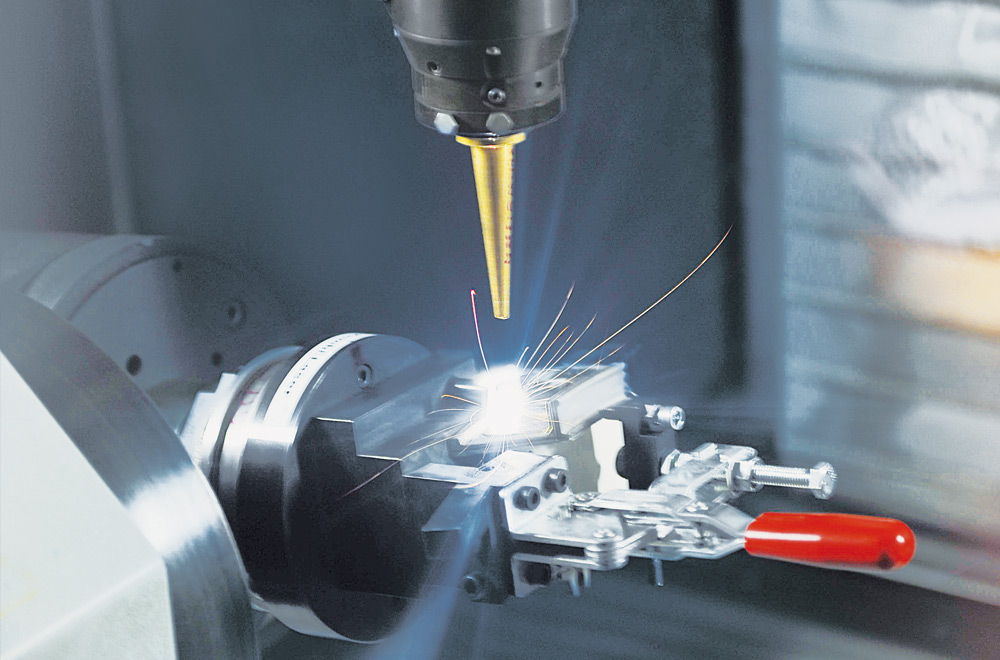

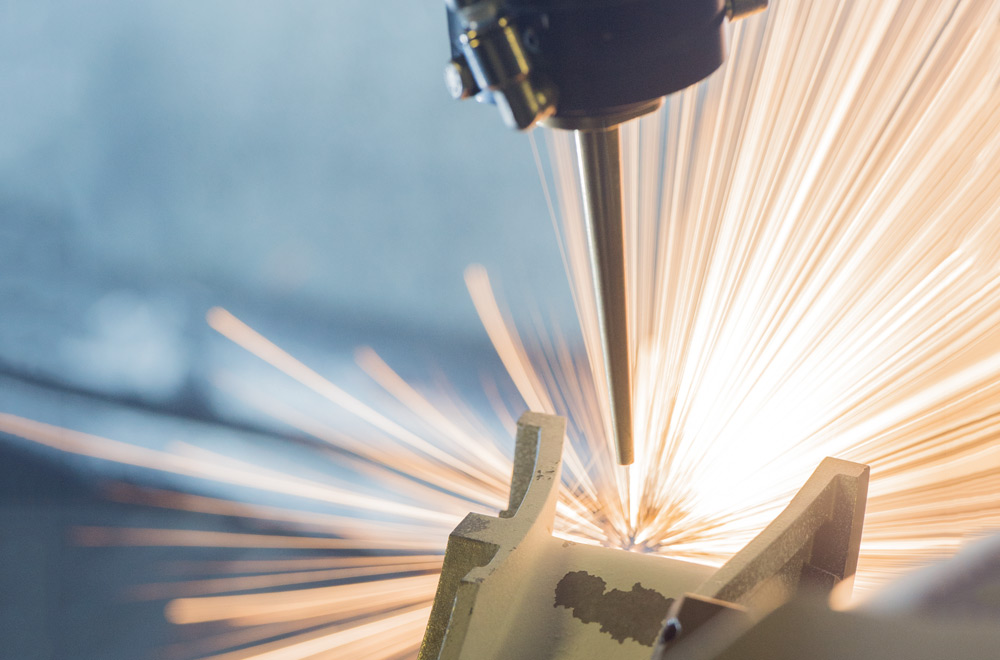

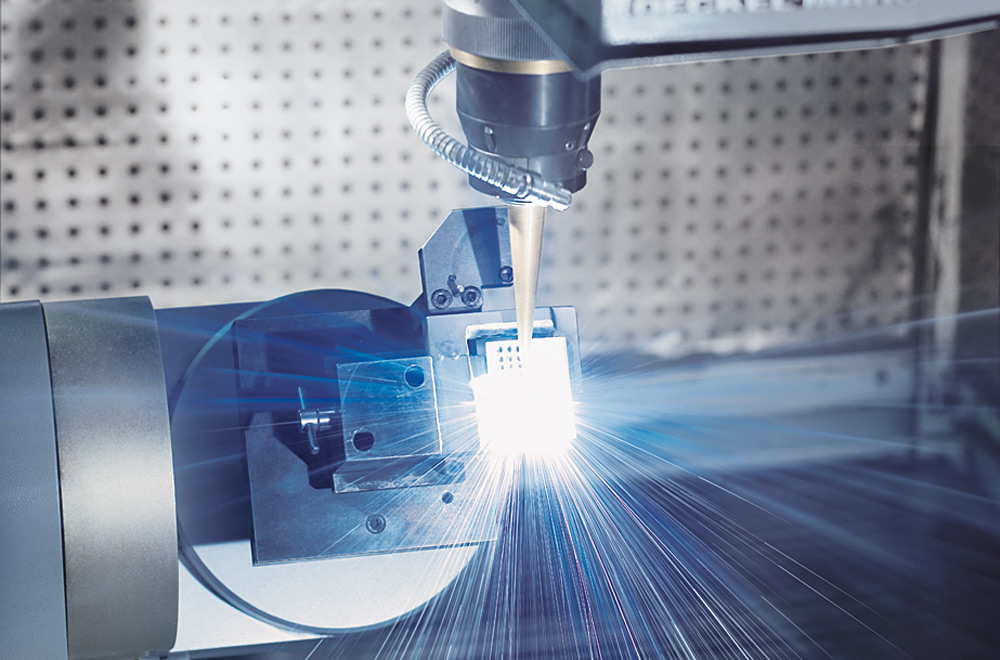

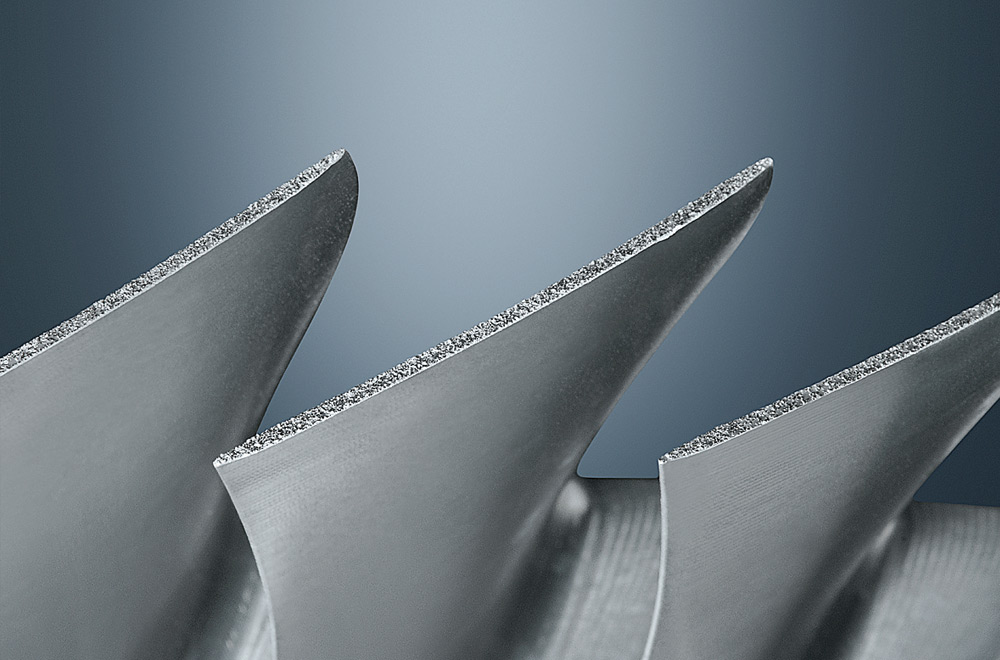

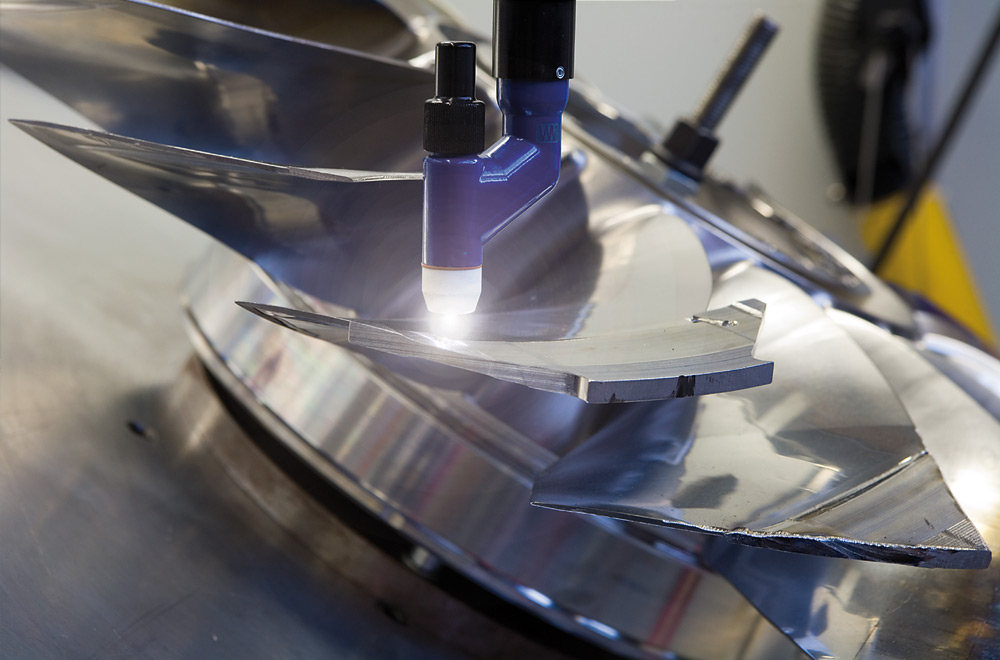

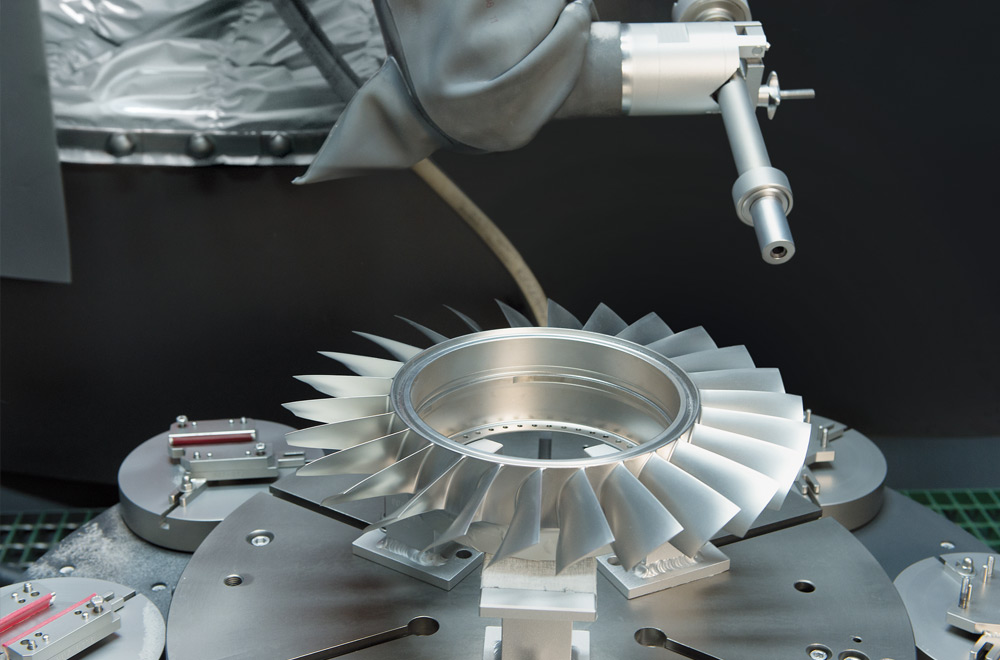

Transforming old into new—an overview of repair processes

Retaining the value of components instead of replacing them. Maintenance and repair are growing in importance. What sets MTU Maintenance apart in this area are its innovative repair procedures.

2 mins reading time published on: 03.05.2017