innovation

Continuum robot offers brand new possibilities

The Center of Competence for turbines and MRO at Leibniz Universität Hannover.

05.2017 | author: Silke Hansen | 8 mins reading time

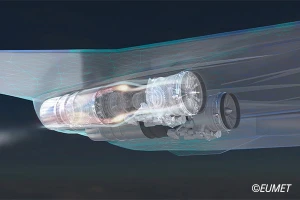

Like a thin snake or long earthworm, the robot skillfully slithers its way through the engine—from the front, in between the fan blades, and then deeper into the engine’s inner workings. Is this the future of engine repair?

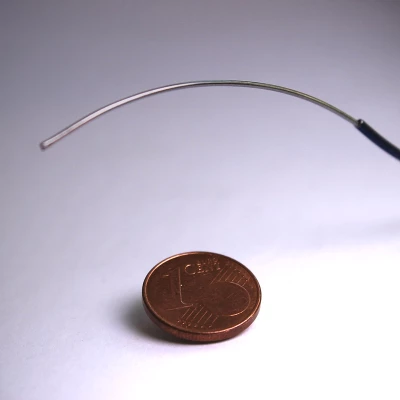

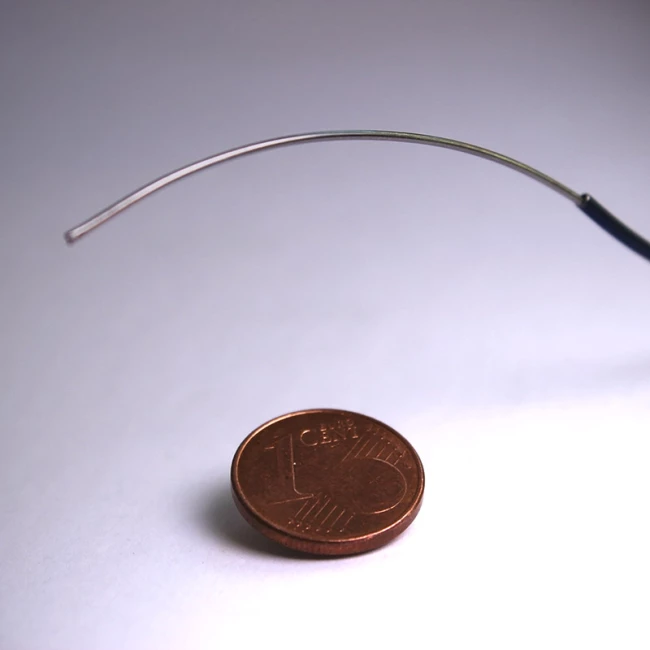

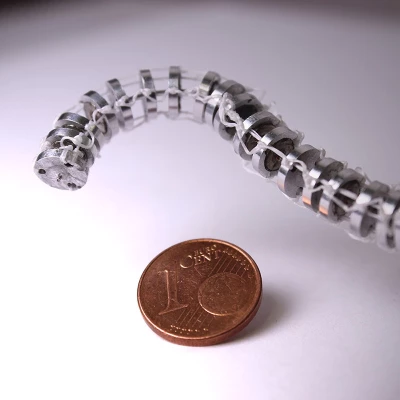

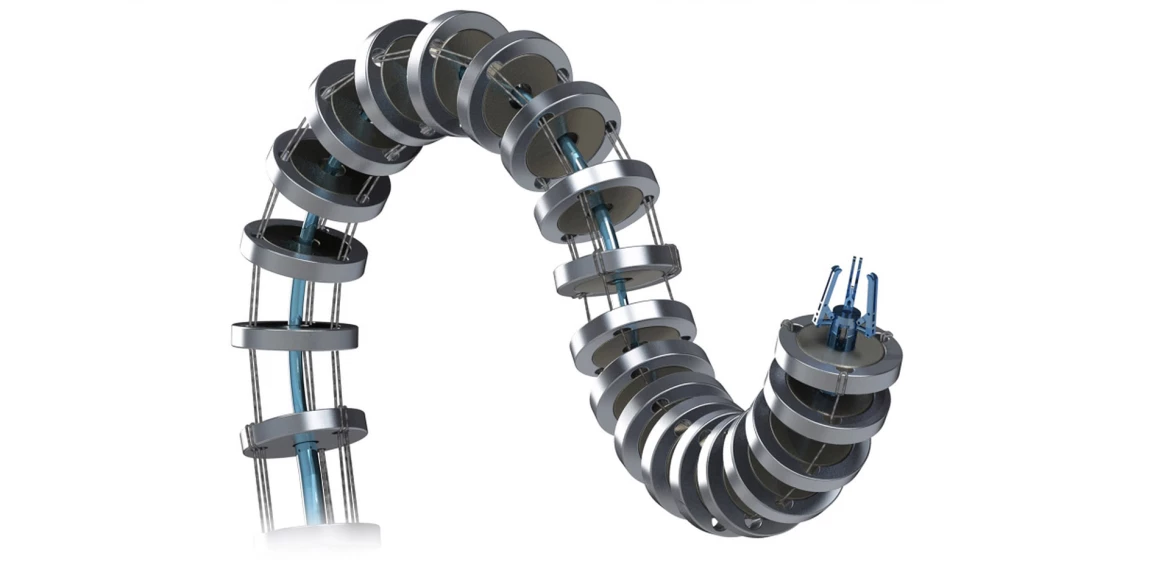

Scientists at Gottfried Wilhelm Leibniz Universität Hannover believe it is. They are researching this completely new method at the Center of Competence for turbines and Maintenance, Repair & Overhaul (MRO), which was founded as part of a scientific alliance with MTU Aero Engines. The miniature robot has a bionic structure inspired by nature—elephant trunks, snakes and tentacles in particular, according to Professor Jessica Burgner-Kahrs. The little helpers that she and her team developed are called continuum robots in the technical jargon because of their ability to function without any joints. Not only do they have the potential to improve minimally invasive surgical procedures in the field of medicine, they also offer brand new possibilities for inspections and repairs in engine maintenance.

Dr. Bertram Kopperger, the head of manufacturing and MRO technology management at MTU, oversees this project: “In contrast to rigid borescopes, the ‘robot’ is much more flexible.” Plus: In conventional borescoping, engineers can access the engine only from certain borescope bosses on the side and the openings are not particularly large. Scientists from Universität Hannover want to develop a first-generation robot with the necessary stability by 2020. Experts at MTU are working in parallel on three different tool attachments— for example, to polish blades or rework coatings. MTU Maintenance provides the modules for testing. “This project is a trailblazer,” says Kopperger. Fly-by-hour contracts, in which the airline pays fixed maintenance rates per flight hour for its engines, are becoming more popular in the aviation sector. Fast, flexible repair solutions are gaining in importance. The robot could do its job while the engine is still mounted on the wing or is at least standing near the aircraft.

Collaborative research into the “regeneration of complex capital goods”

Among other things, this project—which is a part of the Collaborative Research Centres (CRC) of the German Research Foundation DFG—is jointly funded. Assigned the CRC code 871, it deals with the “regeneration of complex capital goods.” “The close interdisciplinary cooperation between various institutions of Universität Hannover and the Technische Universität Braunschweig means several chairs are pooling their expertise,” says Professor Jörg Seume, Head of the Institute of Turbomachinery and Fluid Dynamics (TFD) at Universität Hannover. His institute is responsible for this CRC and has been MTU’s university partner for about 20 years; joining the Center of Competence for turbines and MRO in 2008. Munich values the high level of professional competence in the field of continuous-flow machines offered in Hannover. Its proximity to the headquarters of MTU Maintenance at Hannover Airport was another reason to establish the Center of Competence (CoC) for turbines and MRO here.

Scientists are also carrying out important fundamental research on turbines. A key strength is their thematic range, encompassing aerodynamics, aeroacoustics, aeroelastics and numerical methods for calculation and simulation. In addition, within the mechanical engineering faculty, there is a close research collaboration with the institutes for manufacturing and turbomachinery, according to Seume.

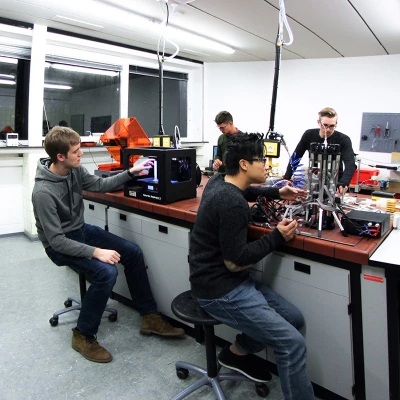

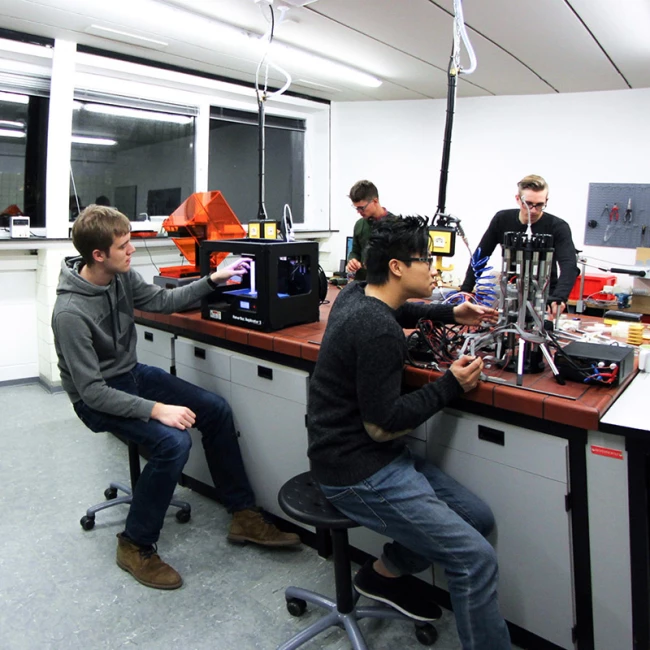

The technical equipment is also very impressive: the TFD alone offers three test rigs for testing, one of which is a completely new turbine test cell. Companies including MTU, Siemens, MAN and Volkswagen rely on this scientific know-how. According to one of the scientists, the collaboration with MTU is very intensive and productive. Currently, the engine manufacturer has placed six ongoing projects at the CoC, with six more currently at the planning stage for 2017 and 2018.

From higher vocational school to a TU9 member

Leibniz Universität Hannover was founded in 1831 as a higher vocational school with 64 students and 14 subjects—and mechanical engineering was one of them from the very beginning. Today the university is a member of TU9, an alliance of leading German technical universities. Along with five other universities and research institutes in Germany as well as the materials and structural mechanics cluster, it is also a partner of MTU, who has founded a joint Center of Competence with each of them. “In this way, we can put selected universities and research institutes in a position to meet our needs and requirements,” explains Kopperger. “It ensures MTU’s ability to innovate, strengthens the networking between science and industry, and helps us attract young academic talent to the company.”

However, these collaborations are by no means a one-way street. Seume values them highly: “We can mutually exploit our skills and learn from each other.” There are numerous advantages to this reciprocal exchange of knowledge. “We’re working with MTU on cutting-edge technologies.” After all, for mechanical engineers, an aircraft engine is the supreme discipline: it is hot, under heavy load and constantly vibrating. It calls for the development of complex methods and long-term solutions. Or, as a scientist at the mechanical engineering faculty in Hannover puts it: “It takes a lot of brain power.”