innovation

Fully automated masking process for MTU manufacturing

How MTU is using an elastomer to revolutionize its surface processing.

author: Thorsten Rienth | 5 mins reading time published on: 11.01.2022

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

When Thomas Kaltenecker, a production planner at MTU Aero Engines, wants to explain the purpose and utility of his futuristic dispensers, he places two photos side by side. The picture on the left shows a large storage facility with multiple floors of silicone rings in dozens of different colors, shapes and sizes hung over, under and alongside each other. The picture on the right shows a few cartridges filled with a gel-like elastomer lying on a table. “Ultimately, both fulfill the same task,” Kaltenecker explains, “namely covering over certain areas of engine components with masking material while other areas that are subject to particularly strong stresses and strains are given, say, a thermal spray coating. The masking makes sure the spray coating doesn’t get onto areas where it’s not supposed to be.”

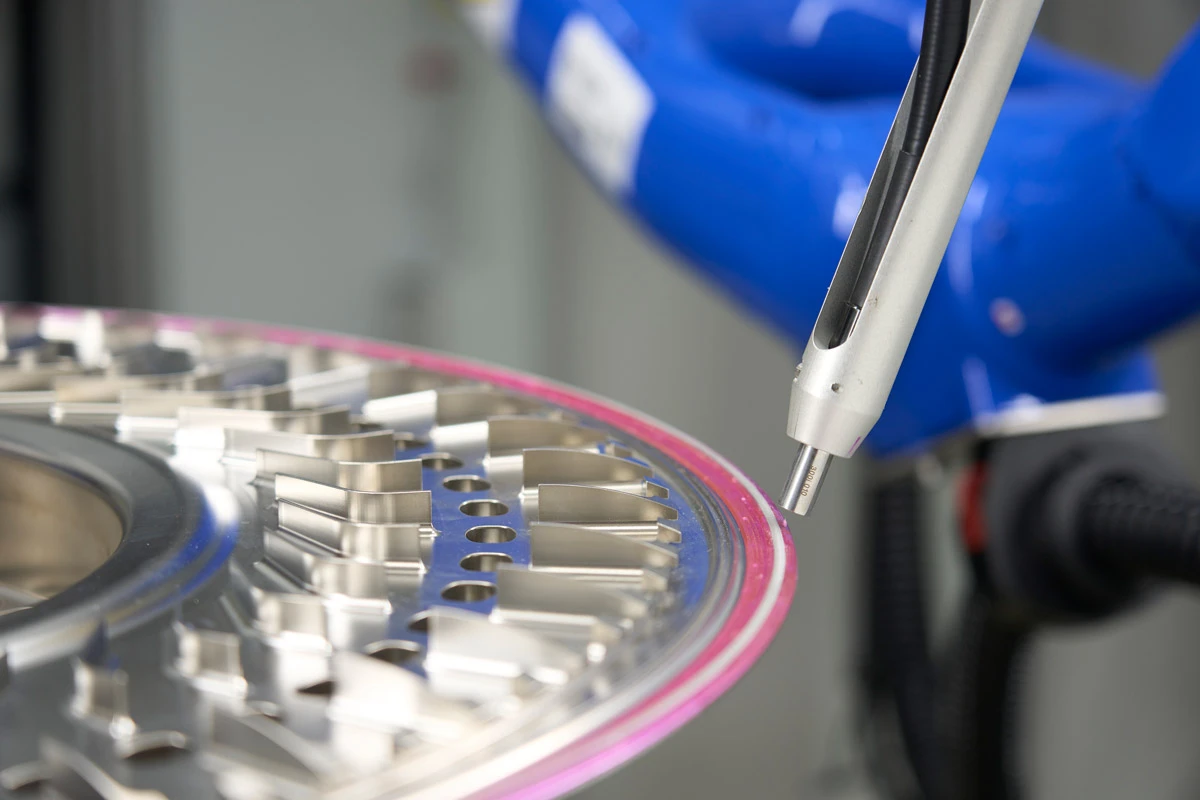

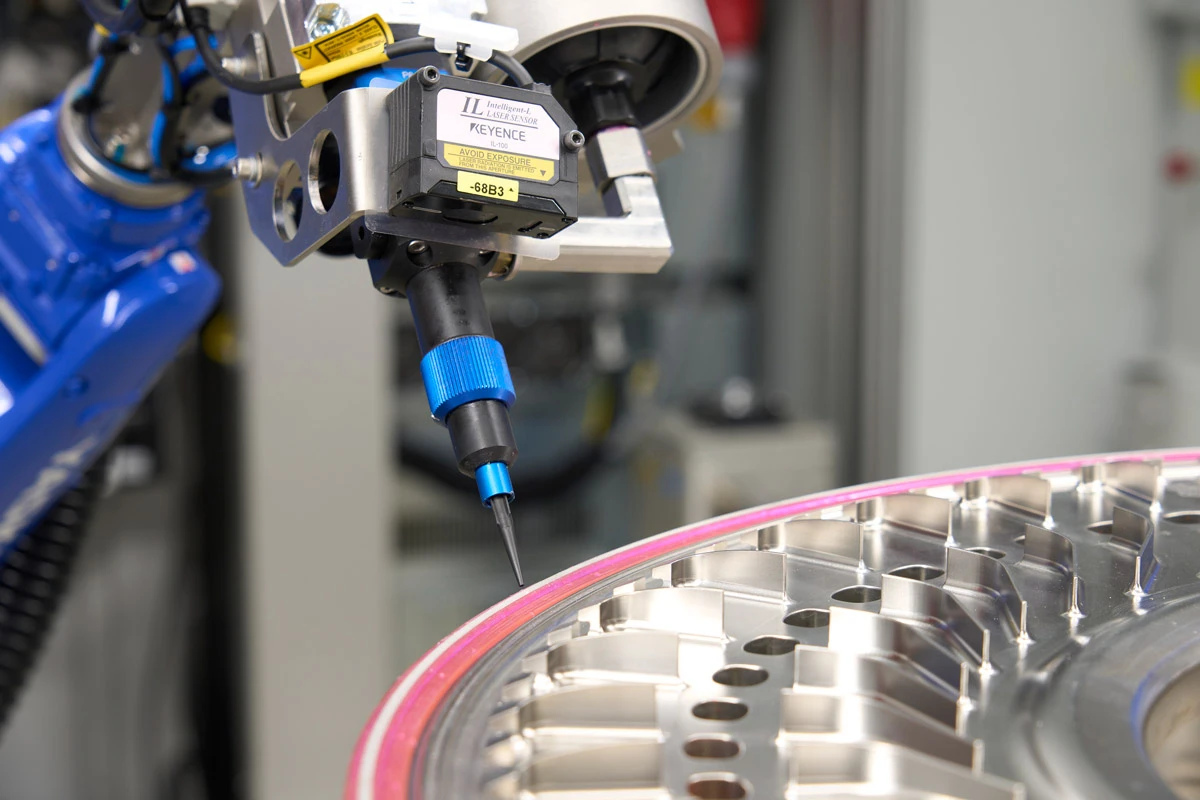

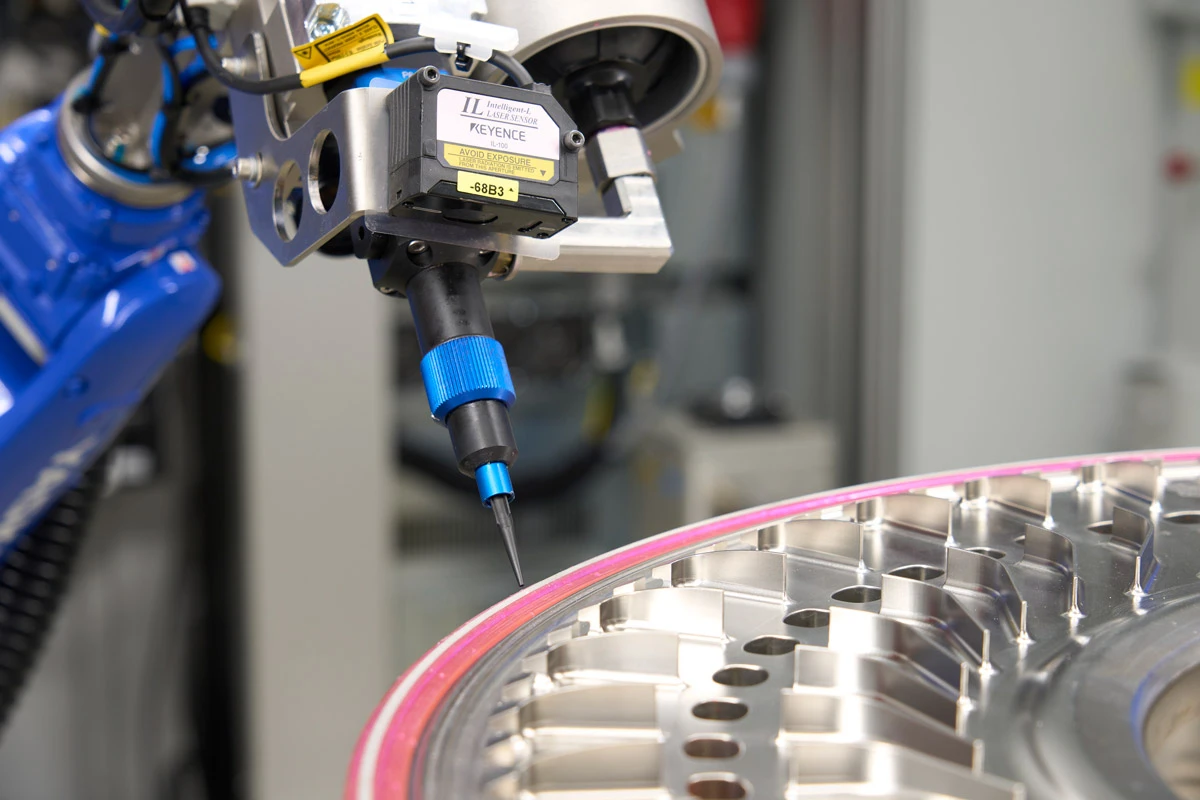

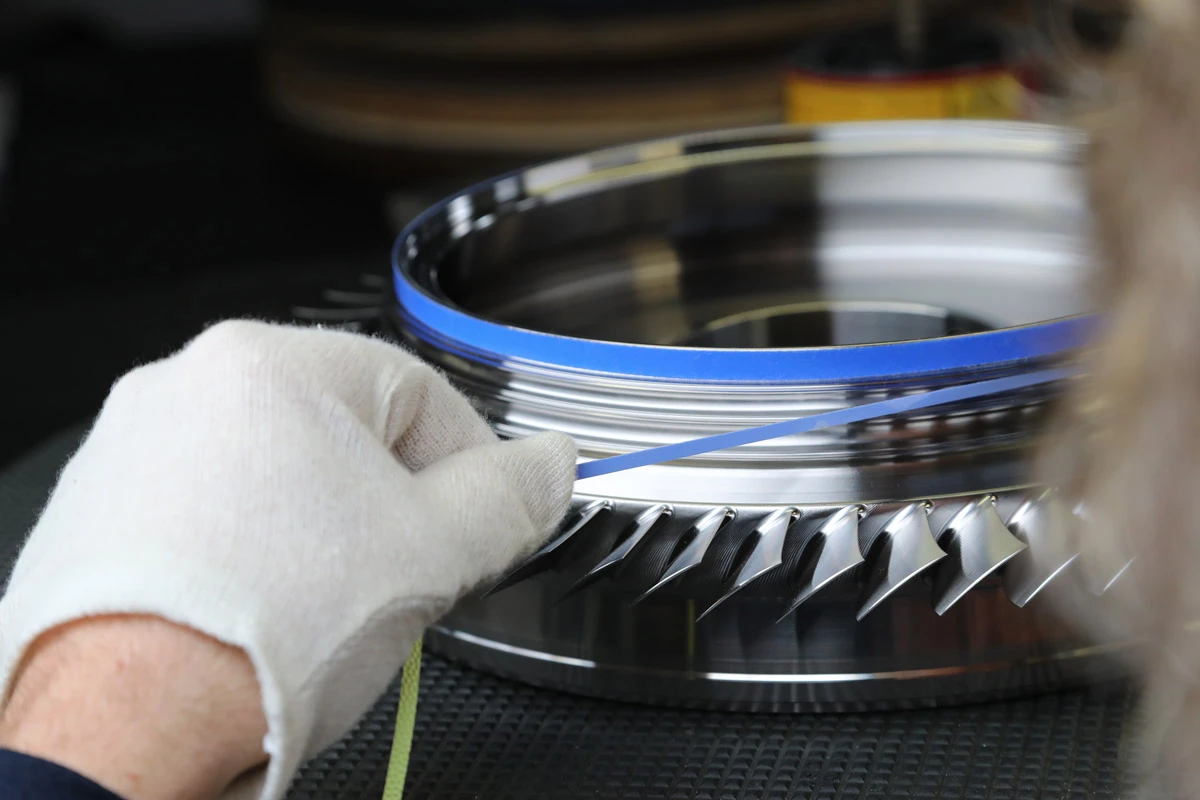

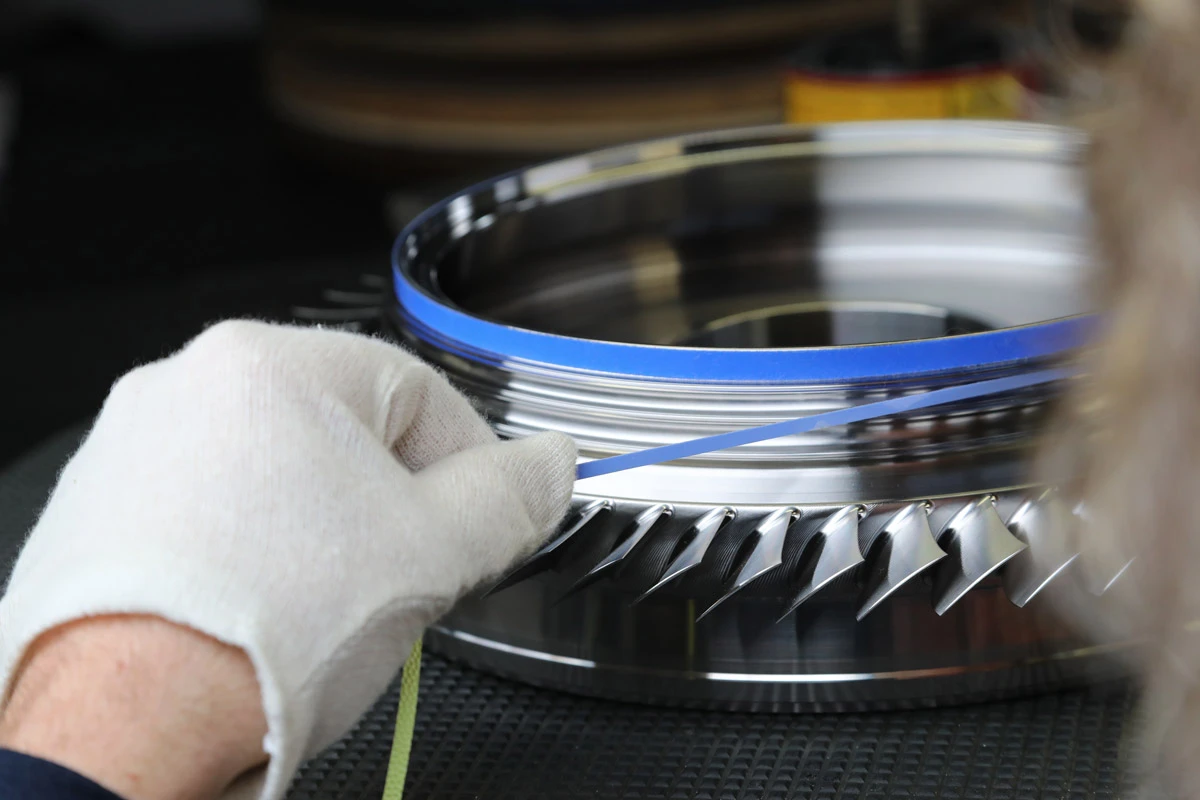

Kaltenecker’s colleagues manually attach, pull on, fit and clamp the adhesive tape, silicone rings, masks or metal covers to these areas at a precision down to fractions of a millimeter. By contrast, the dispensers apply the elastomer in a fully automated manner to the respective sections on the component. Then the fully automatic masking machine’s UV lamp cures the material in seconds. After the masking has passed through the respective manufacturing process, such as thermal coating, shot blasting or electroplating, it can be pulled off the component without leaving any residues behind.

Shorter throughput times, improved quality and reduced costs

SpeedMask® is the brand name of the viscous gel, and DYMAX GmbH is the name of the manufacturer. This company’s UV light curing adhesives are used primarily in the domain of medical engineering; Kaltenecker heard about the product by chance. “Stuff like that could really be useful in our coating processes,” he thought to himself.

Step by step, Kaltenecker began to experiment with SpeedMask®. He tried out various material blends and masking processes—at this point still working manually. Initial tests yielded promising results. Gradually, he found himself spending more and more time not just planning production, but also developing a new masking technique. At the same time, student research projects were busy investigating elastomer 3D printing on engine parts. They attested to its technical feasibility and broad range of applications in MTU production. Shorter throughput times, improved quality and reduced costs deliver first-rate added value.

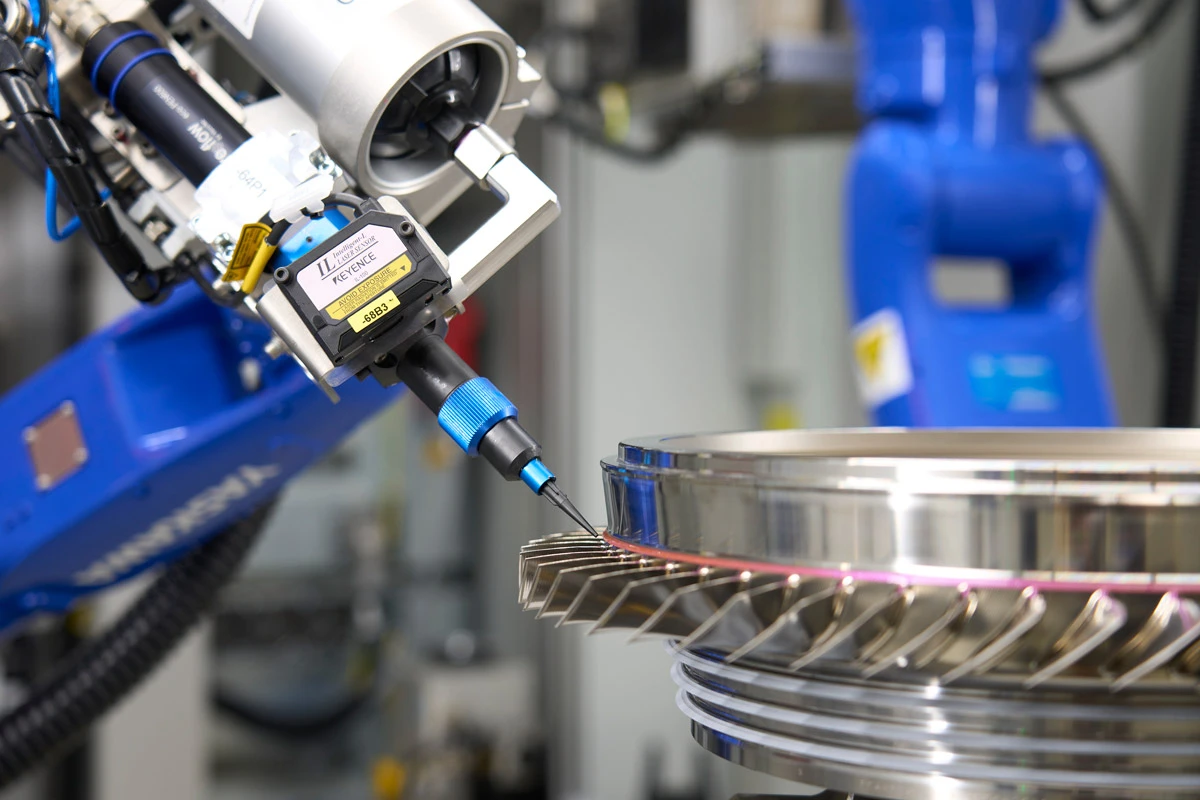

For over three years now, Kaltenecker’s working day has revolved largely around SpeedMask®—and as he tells his story, a blisk revolves in the robot cell behind him. The machine’s optics have recognized that it is dealing with the fourth stage of a specific high-pressure compressor. The control unit loads the corresponding program, sets up the correct dispenser and moves it into position. While the rotary table turns, tilts, lifts and lowers the component, the dispenser unit continuously conveys elastomer from the cartridge. The material is applied along edges with exactly the high precision that is required for tasks like masking on thin blisk blade tips. But the machine can also fill drilled holes or apply masking over broad areas. This process and the fully automatic machine make for an almost endless range of possible applications and variations. “The exact shape of the specific mask is defined by the respective process parameters, such as the type of dispenser attachment, the distance and angle of the dispenser to the component, and the flow rate,” Kaltenecker explains. Then the UV lamp buzzes past and cures the elastomer.

Finally, the machine’s optics come into play again: “They can spot, for example, whether there are unwanted little air bubbles or imperfections in the masking.” That means quality control is included—and there’s a benefit in sustainability terms, too: “Up to now, we’ve been rejecting around 14,000 silicone rings a year at incoming goods on account of deviations. These rejects end up as scrap.”

Surfaces masked to virtually zero tolerance levels

Last summer saw the delivery of a prototype system—one that is quite probably unparalleled worldwide—that enables MTU production to use the innovative material for masking turbine components in a fully automated and effective manner. After putting the system through testing, attention turned to its industrialization: in other words, setting up the masking and curing programs for the first components. While this summary of the machine’s life story up to the present day sounds pretty brief, in fact the backstory is already lengthy: “The prototype was definitely one of our most challenging projects to date,” explains Pascal Malischek, mechatronics and robotics engineer for the Austrian manufacturer Robooptic Systems. “The machine’s entire control system is built in a sort of modular design with free parameters, so that MTU can adapt the masking programs independently.”

This programmability was decisive from MTU’s perspective. Several hundreds of components from the portfolio often pass through various coating stations during their production. Occasionally, component geometries change in the course of design improvements. “In those instances, we have to be able to adjust the respective SpeedMask® masking programs quickly and easily,” Kaltenecker says.

The production planner points to the efficiency aspect of the new system, as regards both OEM and MRO business: “The areas that need to be masked off have become so fine and intricate that masking them by hand takes huge concentration and an inordinate amount of time.” Tasks that took what felt like an eternity to do manually, the SpeedMask® robot gets done in a fraction of the time. “Especially now, with the sharp increase in production for the new programs, this is a big relief for colleagues.” In addition, the material can be processed mechanically, meaning that surfaces can be masked virtually to zero tolerance levels and there is scarcely any limit on the contours that can be produced.

But the advantages of the innovative masking process don’t end there: in certain situations, the masking is applied just once and then used for several successive production steps. This also saves a lot of time and money. And in the MRO sector, the machine could help create customized maskings for the repair of worn engine parts.

The new masking method opens up new potential in engine development

Finally, one other aspect is sure to have a general effect on engine efficiency of engines. “There are places inside the engine that developers would like to improve,” Kaltenecker explains. “But some of their clever ideas were impossible for us to implement before now, because we were unable to get the masking done precisely enough with the adhesive tapes, silicone rings, masks and metal covers we were using.” Of course, validation is required case by case, he notes. But at least now there is a suitable process and a suitable machine on hand.