innovation

On track for emissions-free flight

With its technology agenda Clean Air Engine, MTU is working hard to minimize the climate impact and fuel consumption of aircraft engines over a number of stages.

06.2022 | author: Nicole Geffert | 7 mins reading time

author:

Nicole Geffert

has been working as a freelance journalist covering topics such as research and science, money and taxes, and education and careers since 1999.

Whether exploring faraway countries, discovering new cultures, meeting up with business partners or shipping commercial goods and humanitarian aid – flying brings people together. That said, the aviation sector now faces a headwind as awareness grows about the climate impact of air travel. In response, the industry has identified a number of key challenges. Specifically, it is working hard to progressively reduce the climate impact of aircraft and to deliver the kind of radical solutions that will improve aviation for the long term.

Action is required now. When it comes to the development and production of aircraft, cycles are measured in decades rather than years. If we are to shape the future of aviation, a number of key developments must be set in motion today. Yet the technologies required for this are challenging, and the underlying conditions complex. For example, a host of new technologies are needed before we can burn hydrogen as a fuel in a gas turbine engine or electrochemically convert it in a fuel cell. Fuel cells themselves, electric motors and tanks for liquid hydrogen stored at minus 253 degrees Celsius—all these first have to be developed and designed for integration in aircraft. Moreover, we will need to produce hydrogen for global aviation in sufficient quantities, to do this in a sustainable and costeffective manner, and to create the requisite infrastructure for producing and supplying this new fuel.

With its Clean Air Engine (Claire) technology agenda, MTU Aero Engines is busy developing the solutions that will deliver sustainable commercial aviation and so is once again living up to its reputation as a technology pacesetter.

Three stages to emissions-free flight

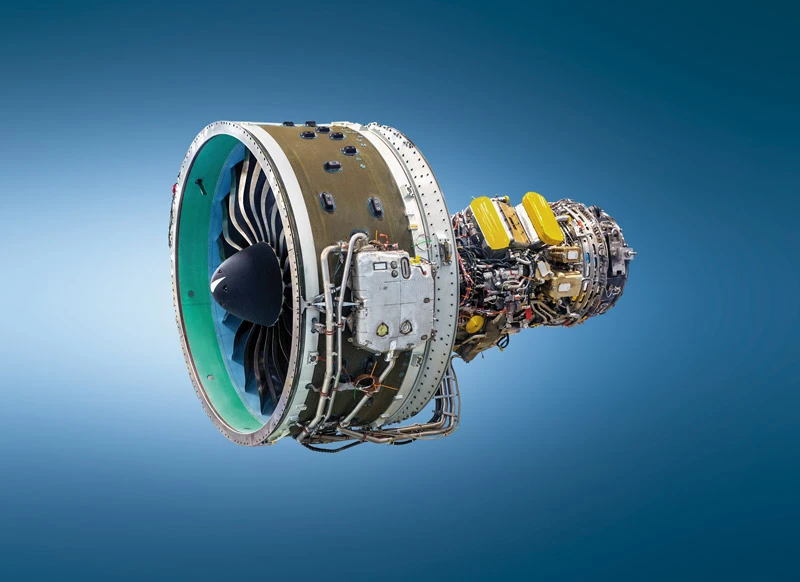

The first stage of the Claire program was the development of the highly efficient engines from the Pratt & Whitney GTFTM engine family. These engines were developed in collaboration with U.S. partner Pratt & Whitney. They are used in modern narrowbody aircraft such as the Airbus A320neo and A220 and the Embraer E-Jet E2 family. The first GTF generation was already regarded as a technical masterpiece. Compared to the previous generation, it reduced fuel consumption and CO2 emissions by 16 percent—one percentage point more than was targeted.

Meanwhile, a new chapter in the GTF success story is about to commence. In the future, the launch of the Pratt & Whitney GTF Advantage™ will deliver a technologically enhanced version of this engine for the A320neo family. The GTF Advantage will cut fuel consumption and CO2 emissions by a further percentage point, thereby leading to an overall reduction in both of 17 percent compared to previous engine generations.

The key improvements here stem from MTU, which is supplying the high-speed low-pressure turbine and the forward four stages of the high-pressure compressor for the GTF Advantage. In addition, MTU also manufactures the brush seals and nickel blisks for the high-pressure compressor—components for which it does not have development responsibility. By contributing these new components, MTU is helping to improve the engine’s fuel efficiency, which reduces the consumption of resources and thereby aviation’s impact on the climate.

Cleaner, quieter, more fuel-efficient: The Pratt & Whitney GTFTM engine family comprises the world’s most eco-efficient engines currently in operation.

Second-generation GTF engine will be even better

Since the geared turbofan engine went into production in early 2016, it has helped aircraft operators save more than two billion liters of fuel, thereby avoiding more than six million metric tons of carbon emissions. Meanwhile, GTF-powered aircraft are now licensed to operate with a 50 percent admixture of sustainable aviation fuels (SAF), meaning a further reduction in CO2 emissions. Upon its market launch, the GTF Advantage engine will be licensed to run on 100 percent SAF.

SAF result in a largely closed carbon cycle. In the best-case scenario, the CO2 released during combustion is then fully recaptured from the atmosphere for use in further fuel production. In addition, initial studies indicate that the use of SAF significantly reduces the formation of contrails.

Alternative fuels: Producing kerosene from renewable energy

SAF can be produced from biomass or from renewable energy via, for example, a power-to-liquid (PtL) process. They can already be used for current aircraft fleets in admixtures of up to 50 percent as a “drop-in” fuel—without the need to adapt the aircraft or engine. This has huge potential to reduce the climate impact of aviation. However, only a few industrial-scale plants are currently in operation, despite the fact that suitable manufacturing processes have been developed and approved. Sufficient production capacity must therefore be created as quickly as possible. Another key challenge will be to make this process more cost-effective. Though not a fuel manufacturer itself, MTU is pressing hard for the use of SAF. For example, it is supporting a number of projects to set up PtL production facilities. Furthermore, MTU Maintenance is the world’s first maintenance company to perform acceptance runs with SAF on the test stand.

To unlock the full potential of the geared turbofan, MTU is already working on the second generation. This includes a program to further reduce the fan–pressure ratio and thereby further increase the bypass ratio. At the same time, it should be possible to further improve the core engine’s thermal efficiency, for example by increasing pressure ratios, integrating compressor and turbine components, undertaking further aerodynamic improvements and using new materials. Any new materials for this purpose must be lightweight, extremely resistant to heat and able to withstand environmental influences. In this instance, MTU is focusing on the very best materials such as sixth-generation monocrystals and powder metals for the turbines. When powered by SAF or liquid hydrogen, the second-generation GTF engine could reduce aviation’s climate impact by as much as 65 percent.

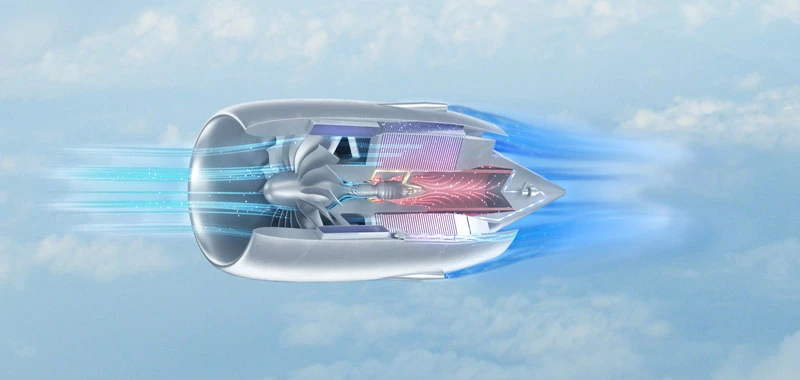

Virtually climate neutral: The WET concept slashes nitrogen oxide emissions. It also substantially reduces fuel consumption, CO2 emissions and the formation of contrails.

WET scores points through heat recovery and wet combustion

The experts at MTU are well aware that this evolutionary enhancement of the gas turbine engine will not be sufficient, on its own, to meet the goals of the Paris Agreement. It is revolutionary propulsion concepts, developed on the basis of the geared turbofan, that will unlock the door to climate-neutral aviation. But to develop them, innovative technologies are required. Together with industrial partners, universities and research institutes, MTU is working hard to deliver the kind of solutions that can reduce climate impact by 80 percent. This is the second stage of Claire, which is scheduled for completion by 2035.

MTU’s favored technology is the water-enhanced turbofan (WET), fueled with SAF or hydrogen. Utilizing thermal energy from the exhaust gas stream, the WET concept uses a heat exchanger to vaporize water, which is then injected into the combustor. The water for this purpose is extracted from the exhaust gas by means of a condenser. This kind of “wet” combustion slashes nitrogen Oxide emissions. It also substantially reduces fuel consumption, CO2 emissions and the formation of contrails. In reducing the climate impact of aviation by around 80 percent, this concept will already be approaching climate neutrality in 2035.

As a gas turbine-based concept, WET profits from the vast know-how at MTU. It is suitable for short-, medium- and long-haul aircraft and therefore covers the sector that is responsible for virtually the entire climate impact of aviation. In addition, its enhanced efficiency cuts costs and saves valuable resources.

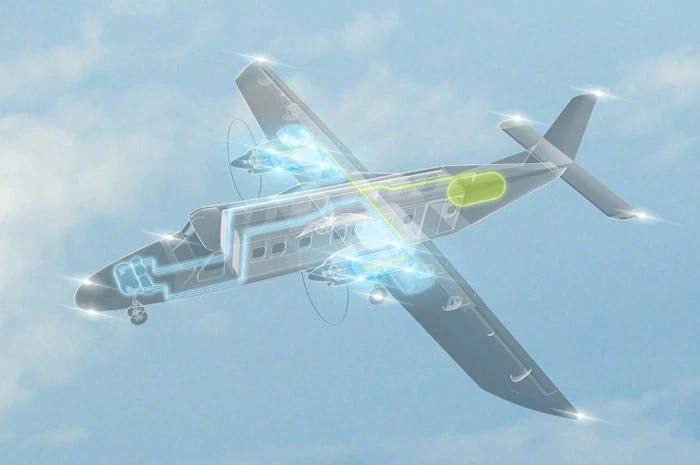

Flying Fuel Cell™: Converts liquid hydrogen into electricity—and thus achieves a virtually emissions-free solution.

Flying Fuel Cell™: virtually emissions-free

In another revolutionary propulsion concept, MTU is investigating options for a full electrification of the powertrain. This, too, forms part of the second stage of Claire and is scheduled for completion by 2035. The most promising of these options is the Flying Fuel Cell™ (FFC), which is set to be deployed first on short-haul routes in regional air traffic. This propulsion system does not produce any emissions of CO2, NOx or particulates. The only emission is water. The FFC reduces the climate impact of aviation by as much as 95 percent—i.e., to virtually zero.

In the long term, hydrogen will serve as the basis for climate-neutral propulsion of the future. MTU has identified three potential applications: it can be burned directly in a gas turbine engine, converted into SAF or converted into electrical energy by means of a fuel cell. The key advantage of hydrogen as a fuel is that it would make aviation carbon free. Per kilogram of fuel, hydrogen contains around three times as much energy as kerosene, which also makes it an extremely attractive proposition for aviation. On the other hand, liquid hydrogen has a larger volume than kerosene. One of the key challenges in the design of hydrogen-powered aircraft will be to accommodate larger fuel tanks. However, it is only when hydrogen is produced with renewable energy that its use becomes genuinely climate friendly. Therefore, alongside the introduction of sustainable fuels in aviation, one of the major tasks over the coming decades will be to ensure a sufficient supply of renewable energy.

Zero emissions within reach

The third stage of Claire is scheduled for completion by 2050. This may seem a long way off—but not for MTU, which is already working hard to further improve the overall efficiency of the geared turbofan and the WET concept. The use of near drop-in fuels (SAF that are chemically modified) would reduce climate impact to a maximal degree. Yet this will also require minor modifications to the aircraft and the engine. If WET is powered by hydrogen, this will bring further advantages—not only lower CO2 emissions but also potential reductions in the weight and drag of the propulsion system resulting from a more compact design.

As efficiency improves, the flying fuel cell should be in operation on short- and medium-haul routes as of 2050. This will further reduce the climate impact of aviation. To help achieve this goal, MTU will be looking to further increase the efficiency of individual components so as to reduce energy use while in flight and thereby take another decisive step towards the vision of zero-emissions flight.

Climate impact: CO2 emissions, NOx emissions and contrails make up the climate impact of aviation.