innovation

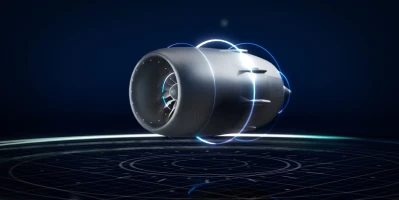

Virtual engine

Digital transformation may be one of the greatest challenges facing the industry, but it is also one of the greatest opportunities. Virtual engines play a key role in engine development, as Dr. Stefan Weber, MTU’s Senior Vice President, Technology & Engineering Advanced Programs, explained in an interview with AEROREPORT.

08.2019 | author: Martina Vollmuth | 4 mins reading time

author:

Martina Vollmuth

holds a degree in journalism and trained as a copy editor for daily newspapers. She is the official spokeswoman for technology at MTU.

Dr. Weber, what is a virtual engine?

In our industry, we see the virtual engine as a real game changer.

It’s a virtual representation of an engine, generated with digital design tools and numerical simulations. Rendering all geometrical and physical properties in their entirety is vital. To do this, various software tools are linked to calculate and construct – that is, to define – the entire engine from front to end.

Why does the virtual engine matter to MTU?

MTU, like everyone else, wants to make the most of the potential that comes with digitalization. We devised a comprehensive strategy to this end: map and render all the value‑adding processes so they can be computed in simulations and connected in smart ways.

The virtual engine will be a cornerstone of productivity and competitiveness for all players in the sector. Anyone who’s anyone in the engine business is really embracing this new technology.

What are the advantages of the virtual engine?

There are two main aspects here: the economic benefits; and the new possibilities for designing, optimizing and certifying engines.

What are the economic benefits?

The numerical approach has already achieved tremendous efficiency gains today, which are sure to increase tomorrow. This significantly reduces the time and effort required to develop and certify engines, and lets us bring new products to market that much faster to meet customers’ ever‑growing demands. Cost‑intensive and time‑consuming tasks such as building test platforms, prototyping and validation testing can increasingly be replaced by simulations.

So how does digital engine optimization work?

Numerical methods give us new ways of developing innovative technologies, for example, new designs or materials. The computational model of the engine is used to determine its overall performance variables such as thrust, efficiency, fuel consumption, pollutant emissions, manufacturability and reparability. It is also used to calculate components’ service life and, by extension, the need for preventive replacement and maintenance.

Before we can quantify the impact of new materials, construction methods and manufacturing processes, and optimize the engine to reduce fuel consumption, pollutant emissions and weight, we have to determine all parameters in the virtual engine model. Of course, this always includes extending components’ service life, ensuring maximum robustness and reliability, and containing costs. We have a lot on our agenda, given that our industry has set some very ambitious requirements for new engines.

What are we doing now?

Let me preface this by saying that much development work remains to be done before we can map an entire engine to a virtual model and make the most of the intended benefits. What matters now is getting from here to there in a way that lets us take advantage of some of the aspects early on. Let me give you the specifics of what we have been up to so far.

We have been using the eProtas platform for quite some time now to develop products. It provides most of our aerodynamic and structural/mechanical computational tools in standard formats. eProtas serves to digitally document the variants of a component’s design, be it a low-pressure turbine or a high-pressure compressor, and their configurations in a transparent way.

Throughout the design phase, we use extensive simulations in a multidisciplinary approach to ensure that all (virtual) engine functions comply with specifications and meet approval requirements. MTU’s Technology 4.0 strategy centers on simulations in materials and manufacturing, the virtual engine and the digital twin. The latter is an exact replica of a real component in the digital realm. This can be anything up to an entire engine. The virtual engine serves to define the project twin; the actual twin reflects the reality of the manufactured and operated product. This is where all data on the component and engine life come together.

One of a kind worldwide

A unique research facility is in the works at the German Aerospace Center in Augsburg—the DLR Institute for Test and Simulation for Gas Turbines (SG).

What’s next?

The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is pushing hard to promote digitalization in Germany. It set up four new research institutes last year. One is the DLR Institute for Test and Simulation for Gas Turbines (SG) in Augsburg, which focuses on the virtual engine. MTU contributed ideas and was deeply involved in the conceptual design. On board as a partner, we share our expertise and experience in developing and operating engines. In return, we can ask for research support and use the testing infrastructure. This affords us many opportunities to advance our cause. We are already tackling some clearly defined issues.