aviation

Engine MRO past and present at MTU Maintenance

Disassembly, repair, assembly and the test stand: lots has changed in the MTU Maintenance shops over the last 40 years. We travel back in time and take a look at what the future holds.

author: Nicole Geffert, Johannes Angerer | 6 mins reading time published on: 01.10.2019

author:

Nicole Geffert

has been working as a freelance journalist covering topics such as research and science, money and taxes, and education and careers since 1999.

Johannes Angerer

partner of the employer branding agency identifire, strengthens brands by researching the formative stories behind them and telling them in appealing forms, whether as text, video or in an exhibition.

- MTU Maintenance was founded 40 years ago

- Engine MRO past and present at MTU Maintenance

- 40 Years

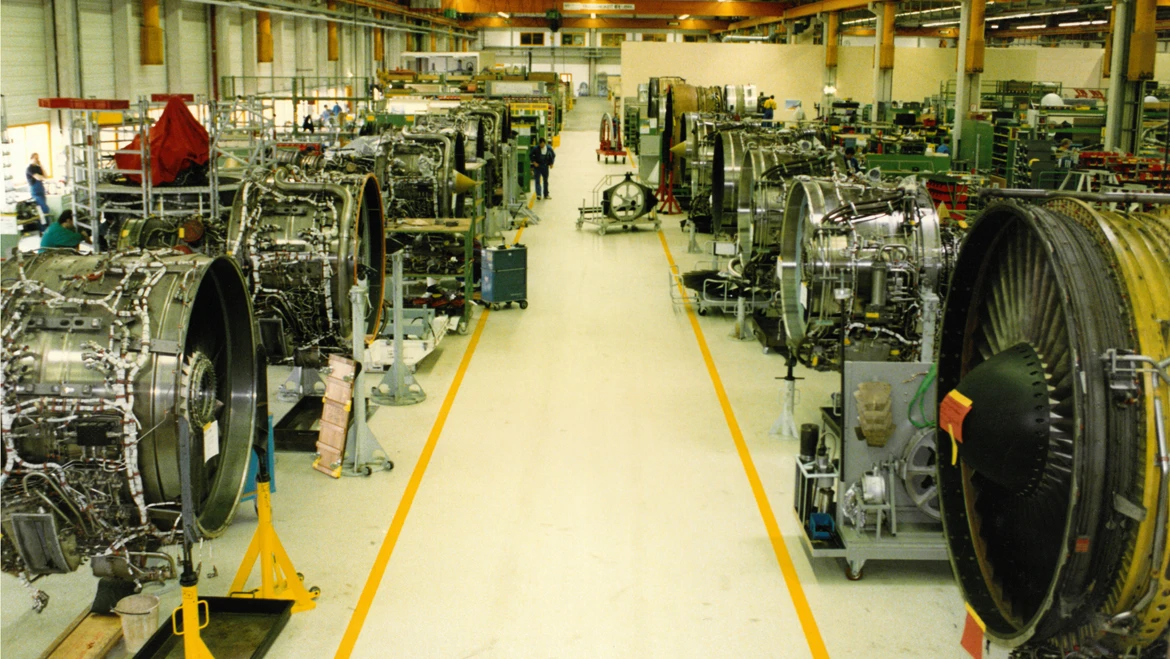

With over 18,000 shop visits under its belt, MTU Maintenance ranks among the top five providers of aftermarket services for commercial aircraft engines and industrial gas turbines. If we take a look back, you’ll see that alongside all the innovations, the company’s 40-year history is also defined by tried-and-true processes. One constant, for example, is the large number of screws that have to be loosened and then removed to dismantle a low-pressure turbine (LPT).

In the 1980s, the maintenance specialists used ratchets and ring spanners for the job. On the desk at each station, a worksheet with details of the steps to perform and a sheet of paper next to it were permanent fixtures. Dieter Schmotz, who has worked as an engine mechanic at MTU Maintenance Hannover since 1981, recalls: “We worked through the instructions step by step. After each step, we noted down exactly what we’d done on the paper, and then signed it, dated it and added our employee stamp. Then we turned back to the module, picked up our tools again and continued the job.”

And what’s changed since then? The tools, for starters. Instead of ratchets, the engine mechanics now use cordless air screwdrivers, for example, which cut the time it takes for an experienced mechanic to disassemble the LPT in half. Manual paperwork has also become a thing of the past – well, almost. Dating, signing and stamping by hand are still an occasional feature of the high quality standards and reliability that the MTU Maintenance shops deliver to this day.

Most processes, however, have been adapted and continuously improved over the years. It’s essential, after all, for a top maintenance provider to move with the times. In line with the company’s MRO 4.0 drive, MTU Maintenance is embracing digitalization and the digital transformation is in full swing in its shops.

With the support of computers, it is now possible to detect technical problems in engines long before they disrupt flight service or create the need for costly, time-consuming repairs. MTU Maintenance’s Engine Trend Monitoring software is a comprehensive solution developed by MTU in-house for monitoring engine parameters. And looking ahead, advanced analytics and machine learning technologies will make it possible to analyze large volumes of data in the future, enabling precise predictions to be made about the condition of engines without them leaving the aircraft’s wing. Such developments improve engine maintenance planning right down to the individual modules, thus helping to reduce costs for the airlines.

MTU Maintenance’s top priority is always to minimize engine maintenance costs and downtime. That holds true for every shop visit it performs – whether the engine comes in for full performance restoration, for life-limited parts to be replaced or for engine parts to be repaired.

Given that metal working generates an incredible amount of noise, it’s impossible to miss the repair areas in the shops. “It used to be far louder in the old days,” says Rudolf Glembozky, a toolmaker by trade who has worked at MTU Maintenance since 1982. He takes the turbine mid frame (TMF) liner – a round, sheet metal part with a diameter of about 150 centimeters – as an example and describes how it was repaired in the past.

In the department he used to work in, one of his colleagues would bring the part in need of repair to the waiting area and put it down with the others. Any particularly urgent parts were given a red sticker. A typical repair would involve changing the four connecting flanges: removing the old ones, welding on the new ones and ensuring all the dimensions were exact. “But first we had to get the part onto the machine. We had no fixture back then, so often two or three of us had to use our brute strength to lift the liner onto the machine.”

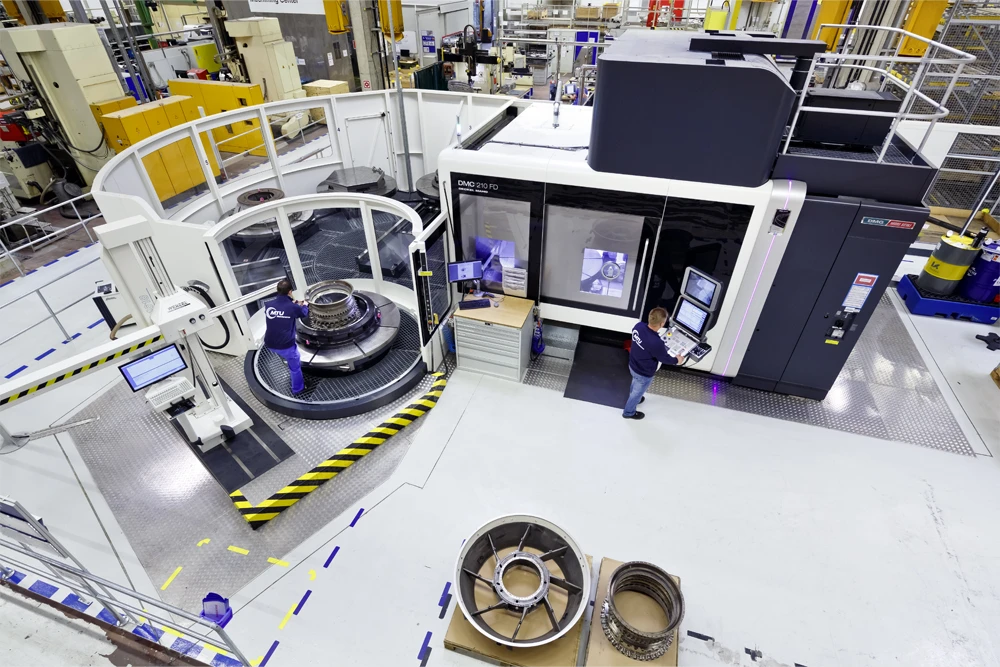

As time moved on, thousands of special fixtures replaced muscle power, many of them designed by MTU employees themselves. Clamping devices, protective covers or special measuring instruments, for example, all help facilitate their work today.

It goes without saying that repair work remains a key area of MTU Maintenance’s expertise, but over the years the company has expanded its portfolio beyond classic maintenance solutions. Today, MTU Maintenance specializes in comprehensive services that cover the entire lifecycle of an engine and provides these services worldwide. One solution is fleet management, where the MTU experts develop bespoke maintenance, repair and overhaul (MRO) solutions for each and every engine in an airline’s fleet, thus optimizing engine availability.

Another example is the company’s engine leasing service. In the aviation industry, where time and costs are of the essence, more and more airlines are taking advantage of aircraft and engine leasing options, which give them greater flexibility and free up additional capital that they would otherwise have to invest in spare engines. To this end, MTU Maintenance Lease Services offers short- and medium-term engine leasing solutions, while SMBC Aero Engine Lease addresses the long-term leasing business. Both companies are joint ventures between MTU and Japan’s Sumitomo Corporation.

left: A V2500 engine undergoes preparations for test runs at MTU Maintenance Zhuhai.

right: Test stand control room at MTU Maintenance. Following repair, every engine is put through its paces on the test stand.

Back to the shop. Following maintenance, every engine is put on the test stand. Frank Reimchen, who schedules test stand operations at MTU Maintenance Hannover, takes us on a short trip back in time to the 1990s. Back then, two mechanics “led” the engine through its test run. One employee from engineering and one from quality assurance monitored the metrics on a screen displaying the 30 most important values all in green.

Another member of the team operated a bulky input console to control the computer system used for the measurements. An eight-channel line recorder took measurements of certain values over time. If you wanted different values, you had to unplug the cables and recalibrate the device. “Our quality engineer at the time, Hans Holpert, wasn’t prepared to put all his faith in the computer, so he would often double-check the engine’s performance during a test run himself with a calculator. It was incredible, he knew all the formulas from memory.”

By the turn of the millennium, it took only three people to conduct a test run – thanks in no small part to the rapid development of measurement and computer technology. By that point, the test technicians had a neat overview of all the relevant values on eight color screens and the system automatically stored the temporal progression in the “history buffer” four times a second. In this modern system, the measurements taken were automatically displayed within the range of the limit values.

And what about now? Today’s engines are supercomputers in themselves that use thousands of sensors to capture huge numbers of megabytes in data every second. “The RB211 was fully analog, and then, in 1989, came the PW2000 and V2500. These engines each had two data channels that delivered 12.5 kilobytes of data per second. Today’s PW1100G-JM incorporates three Ethernet channels that each deliver 100 megabits per second,” Reimchen explains.

MTU Maintenance Hannover invested in a new test cell back in 2007, mainly for the large GE90 engine with its 115,000 pounds of thrust. In anticipation of future developments, however, the test cell was built to withstand 150,000 pounds of thrust. MTU Maintenance Zhuhai also offers cutting-edge testing expertise and the infrastructure to test engines of up to 150,000 pounds of thrust on its state-of-the-art test stand.

And how do things look in the future? Computer simulation technology is developing rapidly and some virtual engine tests are already possible. But these won’t replace conventional test runs in the test cell anytime soon. That holds true for EME Aero as well. Set to launch operations in 2020, MTU’s new joint venture with Lufthansa Technik will, for the foreseeable future, put every engine it handles through its paces on the test stand. Currently under construction in Poland’s Aviation Valley, just a stone’s throw from Rzeszów International Airport, EME will be one of the largest and most advanced MRO service centers for the Pratt & Whitney GTF™ engine family. EME’s state-of-the-art test stand will set new standards, just like the advanced geared turbofan engines it accommodates.