aviation

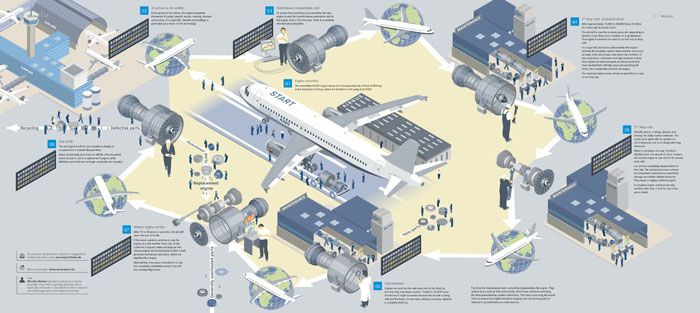

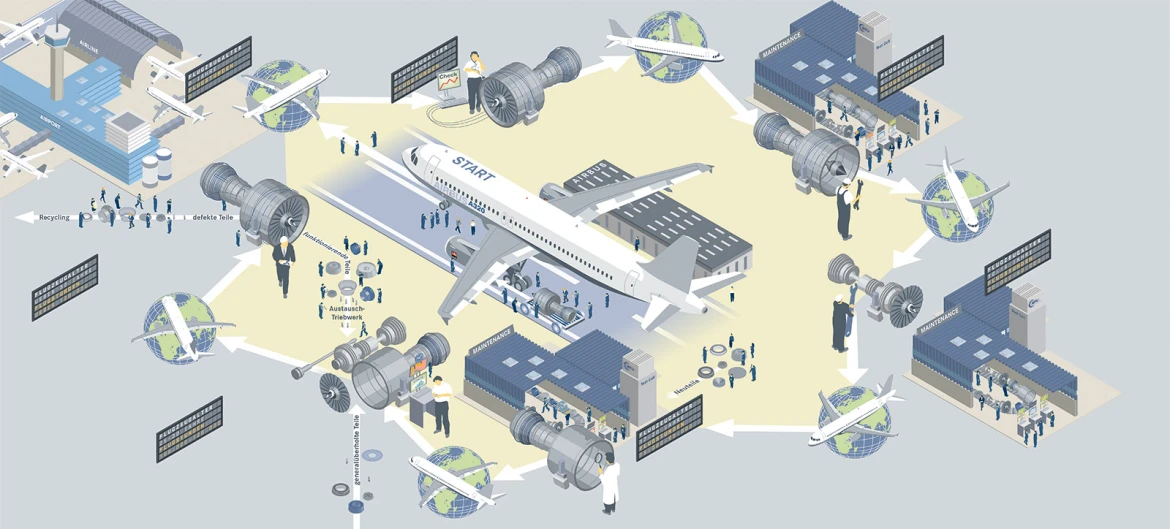

How an engine is maintained

The “résumé” of a V2500 engine from a maintenance perspective.

author: Monika Weiner | 3 mins reading time published on: 01.05.2017

author:

Monika Weiner

has been working as a science journalist since 1985. A geology graduate, she is especially interested in new developments in research and technology, and in their impact on society.

After 30 years in the sky, what better candidate than the V2500 family to present an “engine’s maintenance résumé?” While the oldest variant, the A1, is nearing the end of its service life, the fleet of V2500 A5 engines—the most common variant—is relatively young, with an average age of just over eight years. These engines are either yet to experience their first complete shop visit, or have only recently completed it.

You may also be interested in following content

Engine maintenance résumé for the V2500

Strict safety regulations for aircraft engines require regular inspections of engine performance.

Approximately every 15,000 to 30,000 flight hours, the engine is thoroughly checked and overhauled. Due to legal requirements, certain parts are completely replaced while others are examined in detail and repaired. In each case, the bottom line is to ensure compliance with strict safety regulations for aircraft engines at all times and to restore their performance. The older the engine, the greater the repair depth—the degree to which it is disassembled, inspected, repaired and reassembled. At the end of its “résumé,” owners and maintenance engineers can together decide on how best to continue preserving the engine’s value.