When it comes to engines, what’s better than plenty of power? Normally, the answer is even more power. But in the case of the engine for the Eurofighter Typhoon, this notion appears to be superfluous. Right from the start, the EJ200 met its thrust requirements and to this day, more than 20 years later, even the most discerning pilots say it leaves nothing to be desired. Its entry into service in 2003 marked the beginning of a new era in fighter jet engine construction. This was the first time that four European partners—MTU Aero Engines, Rolls-Royce, Avio Aero, and ITP Aero—joined forces. Their mission: to develop the engine for the new fighter, and with it a thrust delivery system that remains state-of-the-art today. Compared to its predecessor, the RB199 for the Tornado, the EJ200 is in a similar thrust class yet offers a vastly better thrust-to-weight ratio. What made this possible was a genuine technological leap forward, from which MTU continues to benefit.

aviation

New momentum for the Eurofighter’s EJ200 engine

author: Patrick Hoeveler | 7 mins reading time updated on: 09.07.2025

author:

Patrick Hoeveler

is a freelance aviation journalist working for FLUG REVUE and other publications.

Breakthrough in compressors

When the EJ200 was being developed back in the 1990s, MTU was best known in the commercial engine business as a producer of low-pressure turbines. But that was about to change. For the Eurofighter Typhoon engine, MTU was for the first time also responsible for the low-pressure compressor. Inspired by this experience, the company’s engineers began tinkering with a technology demonstrator for a commercial high-pressure compressor and got the chance to make it part of the PW6000 engine program for MTU’s strategic partner Pratt & Whitney. “A high-pressure compressor is actually a core module that manufacturers are loath to hand off to another company. The one for the PW6000 was our ticket into this important area,” says Christian Koehler, Chief Engineer for the EJ200 at MTU. “Our current share in commercial engine programs is a result of the expertise we gained by working on the original EJ200.”

The engineers’ pioneering work on the compressor also included the introduction of blade integrated disks, known as blisks. These sophisticated blade-disk combinations ensure more power with less weight, which is why they are now the standard for modern compressors. The EJ200 was the first engine to feature blisks in fully six compressor stages.

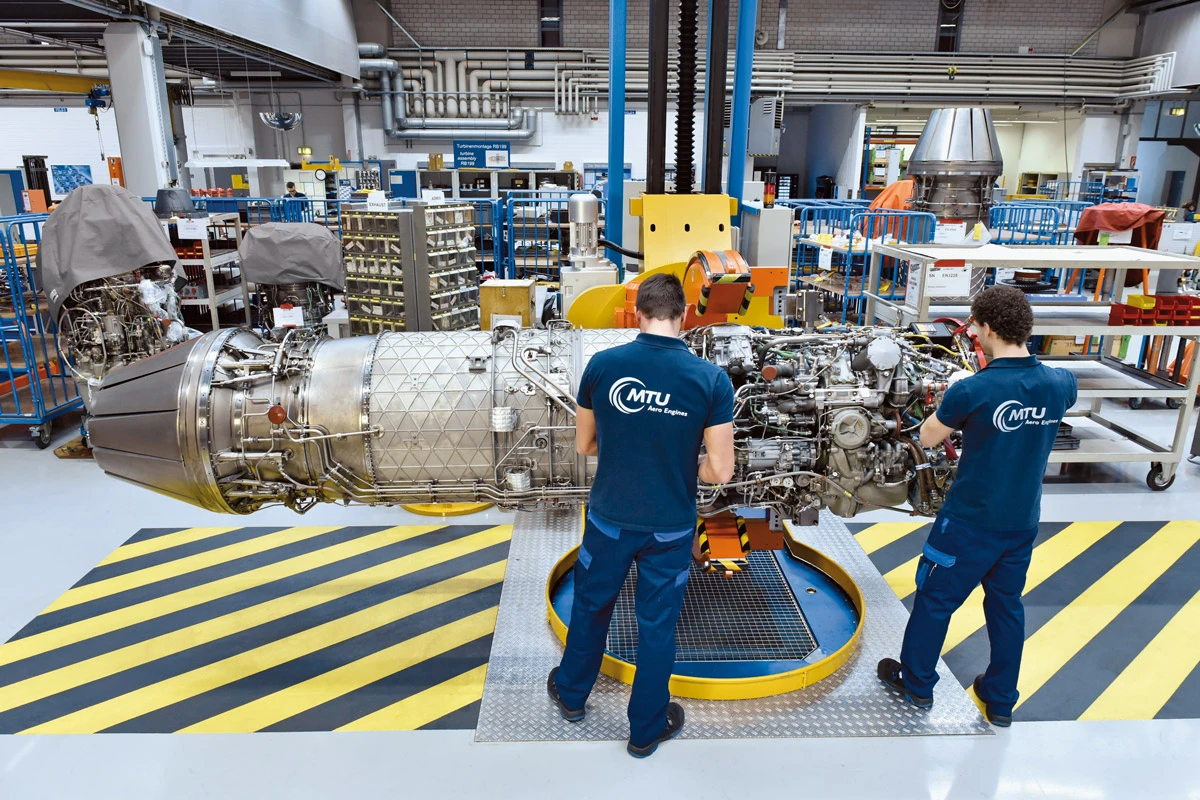

Almost 1,500 engines in service

To date, the four partners have built almost 1,500 EJ200 engines and delivered them to the core markets of Germany, Italy, Spain, and the United Kingdom, as well as to export customers. As part of its approximately 30 percent share in the program, MTU manufactures its high- and low-pressure compressor components as well as the control system for all engines. And, like every partner nation, it has its own final assembly line for the EJ200.Ask a Eurofighter Typhoon pilot from any country what it is about the aircraft that they are most satisfied with, and chances are they’ll say the engine. MTU expert Norbert Schmette from EJ200 flight test operations in Manching, Germany, knows why: “It’s because the pilots don’t have to worry about the engine. Instead, they can devote their full attention to their mission. They also praise the engine’s impressive power and excellent acceleration rates.” Making the engine easy to handle was one of the stated development goals: pilots just have to adjust the thrust lever and the ingenious control system does the rest. This principle has remained the same, even though many modifications have been made to the aircraft over the years. Originally designed purely as an air superiority fighter, the Eurofighter Typhoon was given more and more capabilities. “Nevertheless, the engine’s basic design still meets all the requirements of this weapons system’s expanded mission profile,” says Thomas Lippert, Senior Service Engineer at MTU.

Interview: Stephan Leuthner, Eurofighter Typhoon test pilot, in conversation.

Still the best in power

Given the high amount of power available, operators can equip the aircraft with several metric tons of external load. Even when this brings the aircraft’s weight from the usual 11 tons up to more than 23 tons, it still flies like a fighter. Installing new equipment with higher energy demand—such as a radar system with electronic phase scanning—adds another challenge, as it calls on the engine to deliver more power via the gearbox. Low-altitude, supersonic flight tests conducted over the North Sea showed, however, that the EJ200 still has sufficient reserves of power.

The EJ200’s record for repairs is equally positive. Its current failure rate is just under one incident per 1,000 flight hours, which is excellent for a model in this power category. This is far better than the specification hoped for in the original design. It also means that the EJ200 has exceptionally long maintenance intervals, often requiring a shop visit only once the specified service life of individual components or certain limits have been exceeded. “Some engines achieve reliability stats that even commercial engines can barely match. Many can get close to 2,000 flight hours without having to undergo any major overhaul,” Lippert says.

EJ200

The EJ200 is the result of a European consortium (EUROJET Turbo GmbH) comprising MTU, Rolls-Royce, Avio Aero, and ITP Aero. It is one of the most advanced engines in its class and powers the Eurofighter Typhoon. With a production share of 30 percent, MTU plays a major role in the Eurofighter Typhoon engine.| Max. thrust with afterburner: | 20,000 lbf |

| Max. thrust without afterburner: | 13,500 lbf |

| Pressure ratio: | 26:1 |

| Bypass ratio: | 0.4:1 |

| Length: | approx. 4 m |

| Weight: | approx. 1,000 kg |

A unique approach to repairs

In addition to the more than 300 engines operated by the German Air Force, MTU currently looks after the engines in service with the Austrian Armed Forces as well as MTU modules for export customers. For the engines operated by the German Air Force, MTU doesn’t do this alone but rather together with the German Armed Forces. With this engine repair cooperation, the EJ200 ushered in yet another new era. In the past, industry and armed forces kept their maintenance capabilities separate. But as the Eurofighter Typhoon fleet was smaller than that of previous aircraft, parallel MRO capacity was not economically viable. So in 2002, the German Armed Forces and MTU forged a pioneering partnership.

Since then, repairs have been coordinated by industry, with soldiers always involved in the various relevant areas and key positions at MTU. This opens up both a direct line to the operational units and a dialogue about processes. “In this way, we’ve managed to establish an optimum repair process that incorporates the experience gained by both sides,” explains Stefan Burger, Head of Program Management EJ200 and RB199 MRO at MTU. This work model proved so successful that it was later applied to other programs, such as the MTR390 helicopter engine.

Eurofighter Typhoon

The Eurofighter Typhoon is a single-seat, all-weather, multi-role combat aircraft. It can perform air defense (air-to-air) and air attack (air-to-ground) roles. The multi-role fighter jet is powered by two EJ200 engines from the Eurojet consortium. In contrast to the Tornado, the Eurofighter Typhoon takes off with no afterburner during normal flight operations. This reduces noise pollution at military airfields. The Eurofighter Typhoon can also accelerate into the supersonic range with no afterburner and fly at supersonic speeds for long periods of time. Only a few fighter aircraft in the world currently have this capability, known as “supercruise.”| Altitude: | > 55,000 feet |

| Maximum speed: | Mach 2.0 |

| Wingspan: | 10.95 meters |

| Length: | 15.96 meters |

| Height: | 5.28 meters |

Production gains renewed momentum

Following delivery of the last production engines to the core markets in 2019, the focus lay squarely on repairs. Just two years ago, it looked like volume production for the entire EJ200 engine would peter out and manufacturing would be limited to the spare parts required to repair the existing fleet. But now the situation has turned around and the Eurofighter Typhoon engine is experiencing a resurgence. This is in part due to the most recent orders from Germany and Spain as well as additional letters of intent from international customers. The program is therefore of great importance to MTU:

“The EJ200 still accounts for a significant share of MTU’s annual military revenue and is only midway through its lifecycle. We’ve still got new volume production deliveries coming up, as well as what is now a relatively large fleet in operation that has to be supplied with spare parts and services.”

Director of EJ200 and RB199 Programs at MTU

A resurgence is also happening to the Eurofighter Typhoon as a pillar of the European air defense system. The German Air Force plans to fly this aircraft up through 2060 and it is still finding customers. Indeed, Spain decided to order a second batch, and Germany reordered as part of the Quadriga program with scope for an additional order: “As the F-35 Lightning II can’t do everything the Tornado can, so the potential for further Eurofighter Typhoons is there,” Majewski says. Another option could be a mix of manned and unmanned aircraft. “Tranche 5 of the Eurofighter Typhoon could come into play here, acting as a link to controlling the unmanned weapons systems,” says Wolfgang Sterr, Senior Manager EJ200/RB199 Programs & Export. Just such an offer was recently presented to the customer, and an order should follow before the end of this year. Likewise, the Italian Air Force has already placed an additional firm order. What’s more, as Sterr explains, there are several export campaigns running at present, including in Saudi Arabia, Qatar, Turkey, and Poland: “The Eurofighter Typhoon is nowhere near the end of volume production. As for its engines, the firm orders already on the table guarantee production until 2034, perhaps longer.”

The EJ200’s four partner nations have built almost 1,500 of these engines to date and production is far from over. This modern fighter jet engine remains fit for the decades ahead, not least thanks to a new control system.

You may also be interested in following content

A brief guide: Engine control unit

The DECMU is a fully digital engine control unit that also helps ensure safe operation. For the EJ200, it does even more.

New control system in the pipeline

Sterr notes that the Eurofighter’s engine continues to perform with excellent stability: “Because it works so very well, we’ve made only minimal modifications.” At present, just one major change is in the offing, not due to a lack of power, but rather simply because of a shortage of electronic components. This is making it increasingly difficult to manufacture and repair the existing engine control unit. MTU is therefore completely redesigning this unit—that way, the company can continue to supply and repair such control systems in the future.

Europe’s New Generation Fighter (NGF) is being developed as part of the Future Combat Air System (FCAS). For this fighter jet’s engine, the NGFE, this new Digital Engine Control and Monitoring Unit (DECMU-NG) will provide the technological basis. However, the control system being developed in collaboration with Safran Aircraft Engines is essentially entirely new.

©EUMET

©EUMET

©EUMET

New Generation Fighter: A sixth-generation fighter jet that enables connectivity between the fighter and unmanned components. It uses more advanced key technologies—particularly in the field of electronics and sensors.

The new propulsion system will belong to a much higher thrust class, offer a better thrust-to-weight ratio, and possess stealth capabilities. This calls for another technological leap forward. MTU is drawing here on the technology basis established through the Eurofighter engine and subsequent programs—including in the area of digital control. “MTU wouldn’t be working on control technology today at all without the EJ200. That’s how it all started. We’ll be applying at least a portion of this expertise to the NGFE as well,” Majewski says. And it’s possible that advancements made as part of the new military engine could at some point find their way into future commercial programs—just like the blisks that were first used in the EJ200 and are now an indispensable part of commercial engines. “The EJ200 was a pioneer there and led to innovations in the world of commercial aviation.

As one chapter ends, another begins.