aviation

On-site services: keeping customers flying

To keep cargo customers like Aerologic flying, MTU Maintenance offers a 24/7 on-call service to perform special workscopes on-site at airports or customer locations.

10.2020 | author: Victoria Nicholls | 2 mins reading time

author:

Victoria Nicholls

is a specialist for aftermarket topics such as engine MRO, leasing and asset management, as well as international market trends. The British-born editor lives in Berlin and works for MTU’s corporate communications in Hannover and Ludwigsfelde.

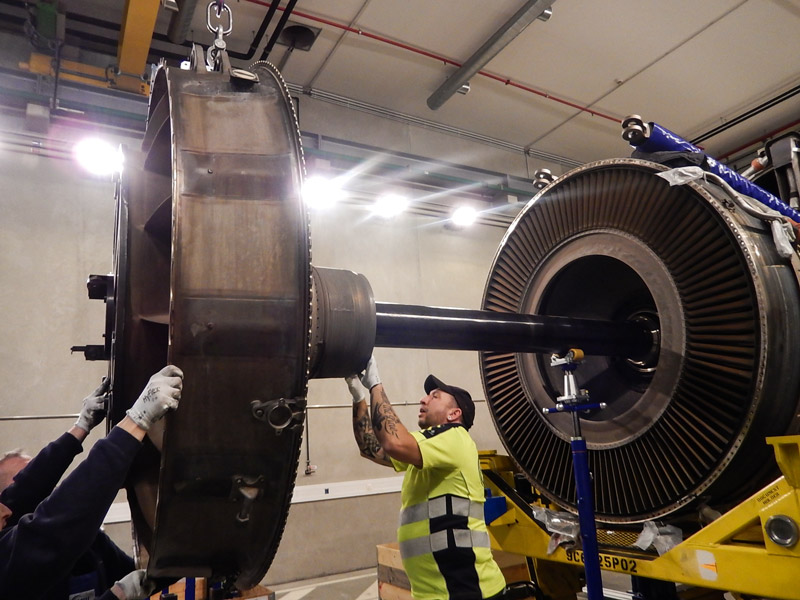

Many air cargo operators are system relevant and currently flying at 100 percent capacity– including MTU Maintenance’s exclusive customer Aerologic, a 50/50 joint venture between DHL Express and Lufthansa Cargo and is pictured here. An on-site team of two line inspectors and a quality engineer from MTU Maintenance Hannover recently made its way to Leipzig/Halle airport (LEJ) to carry out a low pressure turbine stage 6 blade swap on a GE90-110B engine. The scheduled event was carried out according to plan and in turn, the Boeing 777F was able to resume operations without disruption.

MTU Maintenance looks after Aerologic’s entire fleet of GE90-110B engines, and has done since 2012. Recently, the partners renewed their exclusive maintenance, repair and overhaul (MRO) contract by a further twelve years. The agreement includes full support, including engine trend monitoring, fleet management and on-site support as well as spare engine provision. Aerologic is based at Leipzig/Halle Airport in Germany. The cargo expert boasts the most modern freighter fleet in Europe, made up of solely Boeing 777F aircraft capable of carrying full cargo loads of over 100 tons to a range of around 9,000 kilometers.

To keep customers like Aerologic flying, MTU Maintenance offers a 24/7 on-call service to perform special workscopes at airports or customer locations, in addition to MRO and leasing services. These are known as on-site services and are carried out by dedicated engine experts across the company’s global network and by teams based in Brazil, Canada, USA, Germany and China.

On-site services are used to bring the engine back to service in the most cost-effective way possible and, often, under significant time pressure. The workscopes can range from smaller repairs like high-pressure combustor (HPC) boroblending, to top case repairs or even complete module exchanges to rectify a damage and extend on-wing time accordingly. Of course, it is not all unplanned. On-site services also meet customers’ needs when it comes to planned maintenance checks – for instance as shown here. This blade swap was necessary for Aerologic’s continuous operations. MTU is also widening the scope of on-site service offerings for preventive maintenance continually and in combination with its engine trend monitoring system.

Of course MTU continues to carry out these on-site services and helps during AOG events throughout this challenging time. AOG, or aircraft-on-ground, scenarios can be critical and costly for operators, as they disrupt operations. Lately, MTU Maintenance was also able to help a customer in an AOG situation. “We received a call to our AOG hotline at 19:52 p.m. with a request for a part immediately,” explains Arne Straatmann, Head of MTU’s on-site service network. “The MTU AOG team located the part immediately and worked closely with logistics so it could be picked up by a courier that same evening. While the part might not be large, the effect it has on a customer’s operations can be huge. Which is why we do our best to support them as quickly as possible.”