aviation

Tried-and-tested engines

Although the use of computer simulations in the aviation industry is increasing rapidly, real engine and component tests remain essential. Over decades, MTU Aero Engines has built up a global test cell infrastructure, without which modern engine construction and reliable maintenance would be unthinkable.

11.2017 | author: Thorsten Rienth | 6 mins reading time

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

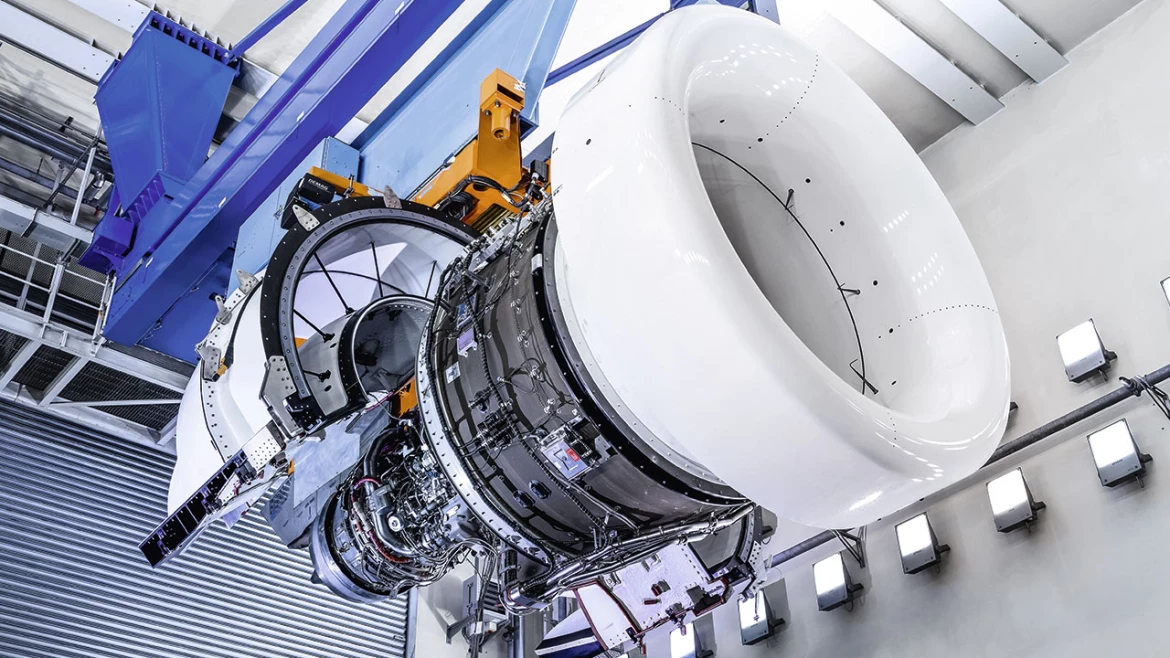

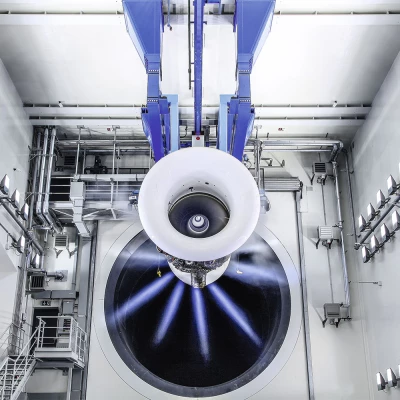

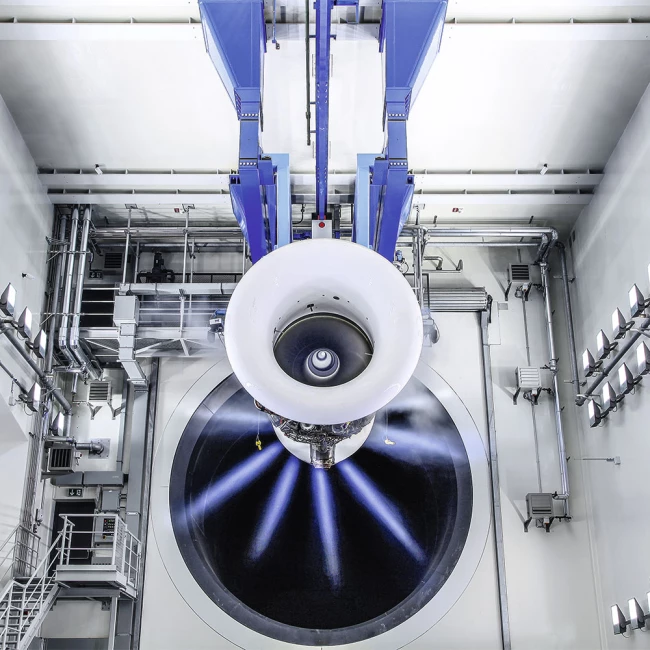

Every step requires the same level of coordination as passing the baton in a relay race: Jack up the straddle carrier with the engine. Pass the bolts of the engine mounting through the openings in the thrust measuring bridge. Hook up the multicoupling system, which allows not only the engine measuring points and test cell measurement system, but also the control and supply lines, to be connected with a single click. All the technicians have to do now is mount the air duct—which thanks to the new quick lock takes a matter of minutes. Then the bellmouth clicks into place like a lens on a camera. While testing gets underway inside, the technicians in the pre-rigging room are getting the next engine ready. And next door, they are packing up the engine that has just come off the test cell.

The processes are tuned for speed. Test cell capacities are precious, and the program volume at MTU Aero Engines in Munich is high: once the Pure Power® PW1100G-JM engine assembly is completely ramped up at the site by the end of 2018, almost one A320neo engine a day will undergo production acceptance testing on test cell 3.

“Acceptance tests are mandatory for all production engines,” explains Kurt Scheidt, who heads up MTU’s engine testing in Munich: without proven performance parameters, no engine will be issued an airworthiness certificate. And that depends on the measurement data produced in an acceptance test run.

Engines in the test cell

MTU’s experienced experts carry out many different types of tests. These include stress tests, which are mandatory for every production engine, and tests under simulated extreme weather conditions to demonstrate the engine’s robustness. To the video

Computer control instead of the human touch

The control center looks like the space operations center from a blockbuster movie: meter-high switchgear cabinets with whirring ventilation systems, knobs, controls and thrust levers recessed into tables and consoles. Add to the mix dozens of monitors displaying all relevant information graphically enhanced and collated in real time. Exhaust temperature, airflow, generated thrust, fuel consumption. On other screens, cameras reproduce every square centimeter of the test cell. For safety reasons, it’s seldom possible these days to view the test engine directly from the control center, and if it is, then only behind centimeter-thick bulletproof glass.

The thrust lever for “running” the engine is also becoming a rarity, because no human hand can match the precise control achieved by a computer. And only when the entries are absolutely identical are the test results considered actually reproducible.

Everything under control Test cell control room at MTU in Munich. Nowadays, the computer is responsible for “running” the engine with the thrust lever, as its movements are more precise than the human hand.

It can take years before a new test cell is ready for operation

The planning, construction and calibration of test cells is a time-consuming business. “Setting up a new test cell can quickly run into years,” explains Thomas Michaelis, senior manager, engine testing, at MTU Maintenance Hannover. “This makes it all the more important to take a farsighted approach.” When a good ten years ago planning for a test cell for large engines in Hannover began, the focus was on the GE90-115B with its 115,000-pound thrust. Nevertheless, the planners designed the test cell for thrusts of 150,000 pounds—to literally give them some excess power. “That will pay off when we’ll have to start accommodating the GE9X in our maintenance facilities in a few years’ time.”

The thrust class is not the only relevant factor when constructing a test cell, however. The engine mounting in the test cell is comparatively easy to exchange for a more powerful system, Michaelis says. “The crunch is the maximum airflow.” For a GE90-115B running at full capacity, this is more than three metric tons a second. “First of all, I have to get this volume of air into the test cell—and out again on the other side.”

Once repaired, each engine has to demonstrate on the test cell that it fulfills the requisite performance parameters again; pictured is a V2500 at MTU Maintenance Hannover.

Once repaired, each engine has to demonstrate on the test cell that it fulfills the requisite performance parameters again; pictured is a V2500 at MTU Maintenance Hannover.

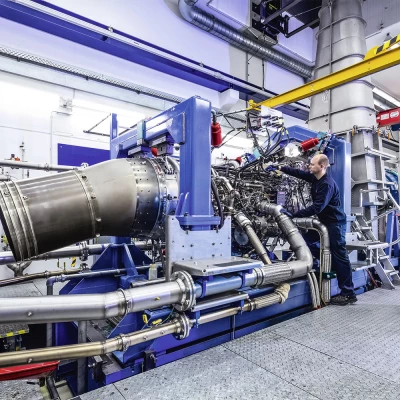

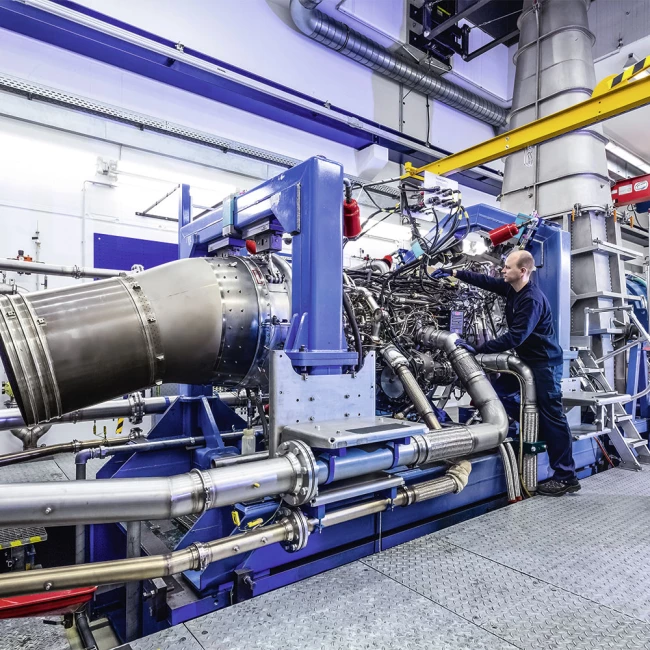

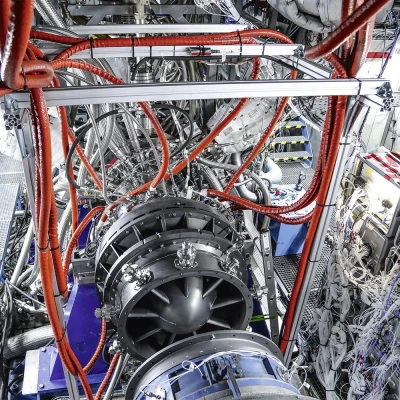

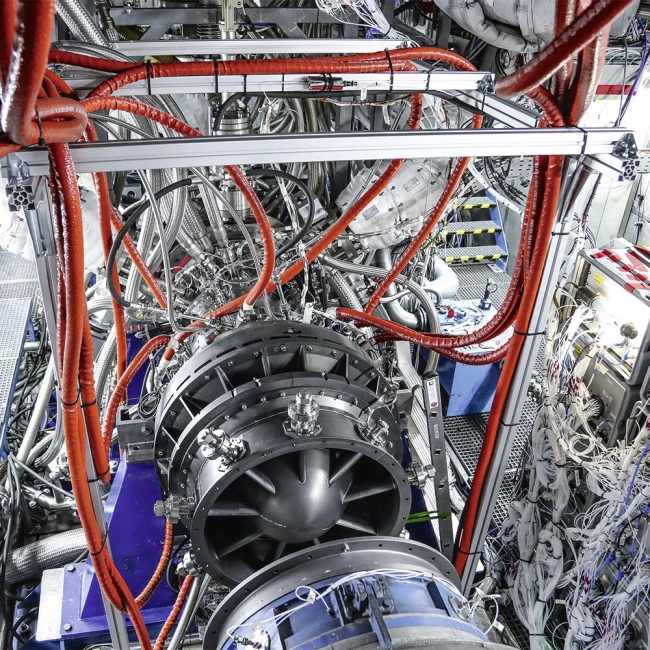

Components and development assemblies are also tested. Pictured is a compressor rig, used to test technological developments for the PW1100G-JM at MTU in Munich.

Components and development assemblies are also tested. Pictured is a compressor rig, used to test technological developments for the PW1100G-JM at MTU in Munich.

The blade tips speed past sensors at up to 500 meters a second

While OEM (Original Equipment Manufacturer) production acceptance tests and the test runs for overhauled engines are similar, development tests have a different focus altogether: they are used to validate new technologies or complete engine modules for future use.

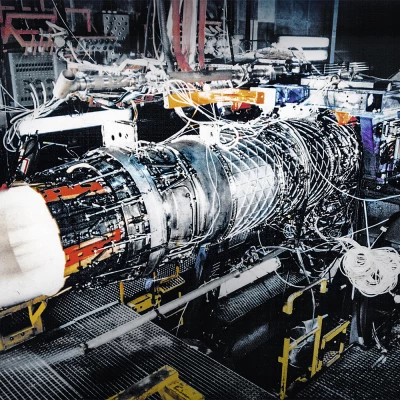

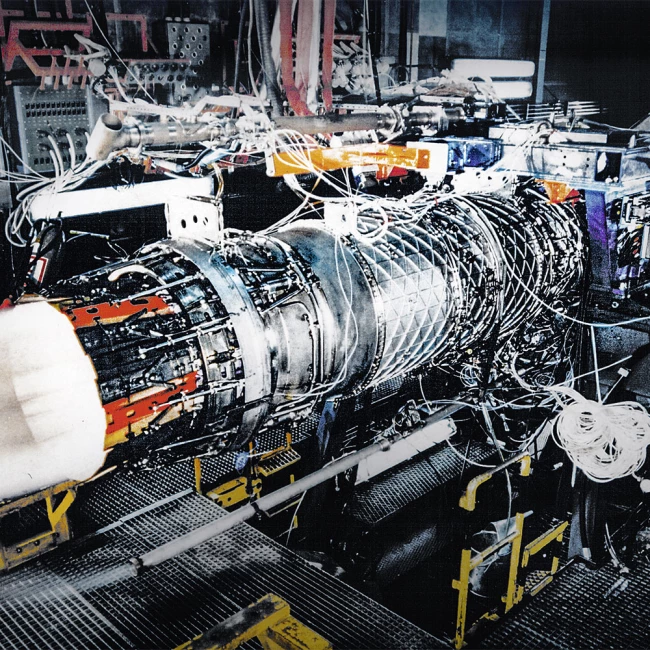

In such cases, test cells resemble a precision engineering workshop: bundled together like a huge bunch of long, thin grasses, hundreds of wires snake out of compressors or turbines. Their ends are rolled up with two or three rotations. Small stickers indicate which sensor the cable is attached to. The measuring points consist of conventional sensors, vibration transducers and resistance strain gauges. The latter are wafer-thin metal strips, through which electric current is passed during the tests. They measure any changes in resistance, however infinitesimal, resulting from the expansion of the metal strips when the engine component expands, whether heat-induced or caused by centrifugal forces. However, this is sufficient for the computer to be able to identify which current change corresponds to which strain. At the same time, an extremely accurate time measurement system is installed. The blade tips fly past the sensors at speeds of up to 500 meters a second.

The wiring must be carried out extremely carefully—meticulously, even. It’s not uncommon to have to connect up over 1,000 measuring points—often also on rotating parts. All of these have to be wired painstakingly by hand. Without a precise overview, the whole structure is worthless. Depending on the complexity, the setup alone can take an entire year.

Engine lifecycle in fast motion

Because no two development tests pursue the same objectives, every setup is unique. During endurance testing on the PW1500G last year, for example, the engineers ran the C Series engine through the engine lifecycle in fast motion. They designed the 13-minute test cycle—consisting of takeoff, cruising and landing—so that after 10,000 cycles, the high-pressure turbine had reached 70 percent of its projected service life. Another focus of the tests was validation of additional engine externals at maximum permissible load—which is twice the permissible load of a new engine. To enable them to generate this, the engineers use a trick: they install balancing weights. The test ran for half a year in two- and three-shift rotation, interrupted only every 500 cycles for borescope inspections.

Given the rapid development of simulation software, why aren’t tests carried out virtually? “Of course it’s possible in the meantime to represent individual tests virtually,” Scheidt says. However, he believes complete engine tests are much too complicated to be run on the computer any time soon. “Even in simple tests, the interactions between the individual engine systems and modules become extremely complex.” How is the software to map a hail strike that also has to be verified? “I also doubt whether the authorities would issue an airworthiness certificate for an engine that has only been tested virtually.” And even if they did: would passengers want to fly in an aircraft powered by such engines?

Test cells for decades

It therefore appears likely that MTU will continue to operate test cells at its sites. In some cases, completely new test cells are set up, in others older ones are updated. Test cell 1 in Munich was originally an afterburner testbed for military programs; later the PW6000, CF34 and PW1200G engines ran on it, for example. Test cell 12, currently scheduled for the T408 engine to power the Sikorsky CH-53K, was previously used for a development program running extensive tests such as bird strike and sand injection. And test cell 3, which now runs the production acceptance tests for the PW1100G-JM engine, is where MTU used to conduct development tests on large engines of higher thrust classes, such as the GP7000 powerplant for the Airbus A380.