aviation

Successful collaboration on the CH-53G

When there are heavy loads to be transported, or troops to be landed in hard-to-reach areas, a high-performance helicopter is an absolute must. For 45 years now, the German Armed Forces have been successfully operating the Sikorsky CH-53G transport helicopter. And throughout, MTU Aero Engines and its predecessor companies have been at their side to take expert care of engine maintenance. Here’s to decades of successful collaboration.

11.2017 | author: Nicole Geffert | 5 mins reading time

author:

Nicole Geffert

has been working as a freelance journalist covering topics such as research and science, money and taxes, and education and careers since 1999.

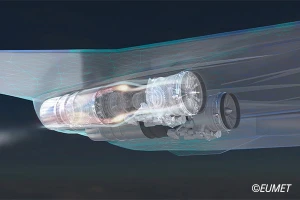

Helicopter manufacturer Sikorsky first developed the CH-53 in the early 1960s for the use of the U.S. Marine Corps, with the first prototype taking off on October 14, 1964. It was a time of rapidly expanding transportation requirements for the German Armed Forces, and the old fleet simply couldn’t keep up. It became clear that the German Armed Forces were going to have to procure a new model, and in the end they opted for the CH-53, powered by two General Electric (GE Aviation) T64 engines. On July 26, 1972, the German Armed Forces officially took delivery of the first “medium-duty transport helicopters” (MTH) from an overall order of 112 aircraft. Though first delivered to the Army Aviation Corps, the aircraft have been operated by the German Air Force since 2010 following the reshuffle of the German Armed Forces.

From the beginning, MTU was on hand to ensure the safe operation of the T64 engines, which were produced between 1970 and 1975 in a collaboration between GE Aviation and Klöckner-Humboldt-Deutz. In Munich, MTU was chiefly responsible for assembly and acceptance testing, and a total of 247 T64 engines were delivered. “These days, our work on the T64 focuses on maintenance. In the average year, 20 of these engines come through our doors for technical monitoring, repair or general overhaul,” says Florian Pulfer, Head of Program Management for Helicopter Engines—Service & Maintenance at MTU.

Adapting to changing operating environments

Over 45 years of service, missions and requirements have changed. The CH-53G and its T64 engines have had to be modified and developed to equip them for extreme weather conditions and geographical locations. In close consultation with the German Armed Forces, this led to the launch of an upgrade program for the CH-53G. By 2014, 166 engines had been brought up to date in collaboration with the German Armed Forces.

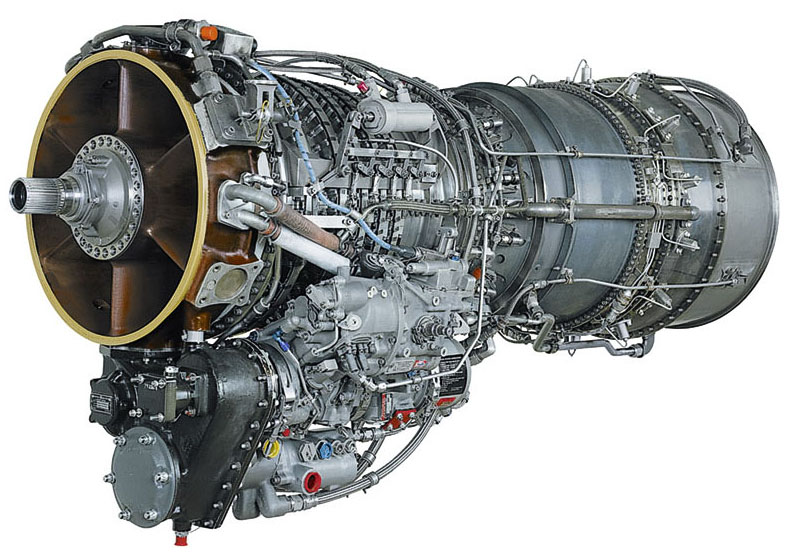

The upgrade encompassed almost a dozen components, from the fuel pump and fuel regulator to the combustor inserts and gas generator turbine. The upgraded T64-7 became the T64-100, with a maximum power output of 3,229 kilowatts—300 kilowatts more than its predecessor. This boost was achieved by installing newly developed turbine blades that allowed for an increased combustion temperature. In addition, the helicopters were equipped with sand filters to minimize the wear resulting from sand ingestion. The German Armed Forces leapt at the opportunity to collect the last of the 166 upgraded engines directly from MTU in Munich in November 2014—in a CH-53G, of course.

T64 The turboshaft engine with a maximum thrust of 3,229 kilowatts that powers medium-size transport helicopters, such as the Sikorsky CH-53, was built between 1968 and 1975. At its Munich site, MTU carried out assembly and acceptance test runs for this engine manufactured in cooperation with GE and Klöckner-Humboldt-Deutz (KHD). Today, MTU’s T64 activities focus on on maintenance. In 2014, the program to upgrade the T64-7 engines to the enhanced T64-100 standard was completed. The Bundeswehr collected the last T64 from MTU in—what else?—a CH-53G.

100,000 flight hours

The German Air Force plans to continue operating the CH-53 fleet until 2030: “The team at MTU has done everything to ensure that the engines will be able to carry out their tasks efficiently and reliably well into the future,” says Wolfgang Gärtner, head of Helicopter Engine Programs at MTU. The best demonstration of this is the fact that the T64-100 reached the 100,000 flight hours mark on June 18, 2017.

The decades of trustworthy collaboration have extended to other military programs, and MTU employees work shoulder to shoulder with German soldiers on engine maintenance in a variety of collaborations. The idea was first developed and implemented by MTU together with the Bundeswehr—the first of its kind. Since the model proved so effective for the Eurofighter EJ200 engine, it was rolled out to other military engine programs, including the RB199 Tornado engine and the MTR390 powering the Tiger combat helicopter. The model saves money and time by pooling resources, and ensures the best possible provision of service-ready engines for the troops that need them.

As Klaus Günther, Head of Military Programs at MTU, comments: “The German Armed Forces can rely on MTU at all times to provide innovative maintenance and repair techniques and personal customer service.”