good-to-know

A brief guide: The electrochemical processing of components

With the (P)ECM process, components that are difficult-to-machine with complex geometries can be produced with low wear and at reduced cost. We explain how it works.

author: Isabel Henrich | 4 mins reading time published on: 19.09.2024

author:

Isabel Henrich

studied political science and communications. At MTU, she coordinates the editorial process of AEROREPORT and is responsible for the conception and development of its content.

The aerospace industry is working on ways to make aircraft engines consume less fuel, produce lower emissions and become quieter. Weight is a key consideration here: the lighter an aircraft’s components, the less energy it has to use during flight and the more kerosene can be saved.

This effect is also achieved by “blade integrated disks,” or “blisks” for short, where the blade and disk consist of a single piece. These high-tech components used in compressors have a major advantage over their counterparts with individually fitted blades: the integral design reduces the rotor disks’ edge load and thus reduces weight. Eliminating leaks also helps make the compressor more efficient. As a result, engines become more compact and lighter overall and consume less fuel, which in turn reduces CO2 emissions.

The front stages of a high-pressure compressor are made of titanium. However, because the rear stages are exposed to significantly higher temperatures of up to 650 degrees Celsius, they are made using nickel-based materials, which have the necessary resilience to such temperatures. While the contours in titanium blades are traditionally milled out during production, nickel blisks are difficult to weld and machine. Added to this is the extremely complex 3D geometry of the blisk blades. Given these factors, MTU Aero Engines opts to use (precision) electrochemical machining, or (P)ECM.

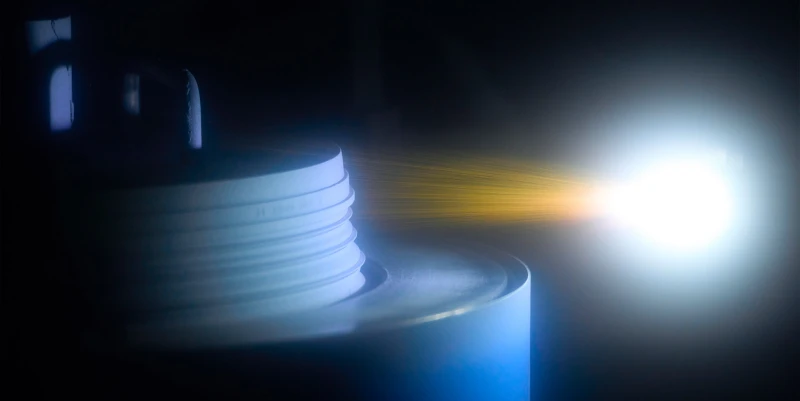

With the (P)ECM process, MTU is using a cost-effective and low-wear alternative to conventional milling for machining nickel blisks.

Innovative manufacturing technology: Electrochemical machining (ECM)

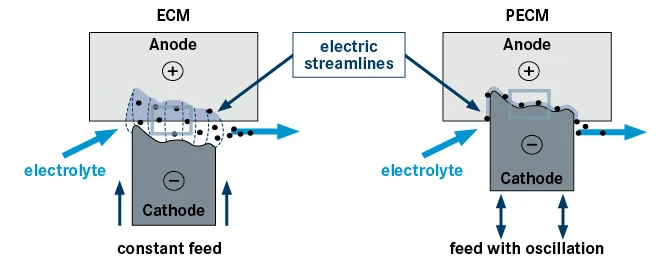

Electrochemical machining, or ECM for short, is a generic term covering various processes. All of them use an electrolyte and an electric current to dissolve a metallic material in order to form it into the desired shape. The workpiece to be processed serves as the anode (positive pole) and the 3D metallic molding tool as the cathode (negative pole). The electrolyte is an aqueous solution of sodium nitrate that flows between the anode and cathode. This liquid has three functions: it creates an electrical connection, removes the ablated material, and draws away the resultant heat and gases.

In the ECM process, the component is machined with unpulsed DC voltage through constant feed of the tool cathode until the desired workpiece contour (component contour) is realized. The conventional ECM process achieves high ablation rates with rather low precision and an imaging accuracy of 0.1 to 0.5 mm.

Pulse ECM, which is based on this ECM process, works in much the same way: the component is machined through constant feed of the tool cathode, but here it’s electrically pulsed DC voltage that’s applied. Although the process has a lower ablation rate, it is also more precise.

PECM: MTU is a pioneer in implementation

The greatest precision can be achieved with the PECM (precision electrochemical machining) process. It uses narrow working gaps and thus enables precise mapping of complex geometries. Since the electrolyte exchange does not work optimally with small gaps, the process is carried out with a mechanically pulsed cathode. The working current is always switched on when the cathode is close to the smallest gap. MTU developed this process and applied it for the first time worldwide to manufacture the component geometries of nickel blisks. MTU makes the PECM equipment as well.

How it works: Use an electrolyte and an electric current to dissolve a metallic material in order to form it into the desired shape. The workpiece to be processed serves as the anode (positive pole) and the 3D metallic molding tool as the cathode (negative pole).

Efficient processing through subtly different ECM techniques

One of the advantages of electrochemical ablation over conventional milling is that, because the tools make no contact with the component, they experience virtually no wear and tear and leave no machining marks on the component. Both these factors reduce costs. Unlike milling, the PECM process can’t be used to form sharp edges, for example, as the streamlines condensing at the edges result in more ablation.

You may also be interested in following content

Thermal coating techniques

Temperature resistance, corrosion resistance, hardness, stability, compressive strength, durability—every single engine component must fulfill specific requirements. Coatings help make sure they do just that. The range of techniques available is massive. Here’s a selection.

The average processing time per nickel blisk is 24 hours. To make the process as efficient as possible, the three ECM methods are used in different processing steps. Standard ECM is used for roughing, intermediate, and edge processing, while pulse ECM and PECM are mainly used for the finishing touches.

Next development milestone

For several years, MTU engineers have been researching how to reduce the harmful chromium VI compounds produced during electrochemical ablation. As part of a technology project, they showed that these Cr(VI) compounds can be reduced to Cr(III) compounds with an alternative saline solution—iron(II) nitrate—and separated from the system along with the ECM sludge. The project team at MTU developed an ion exchanger process that automatically produces iron(II) nitrate and continuously doses the substance, managed by the control room, into the (P)ECM electrolyte management system as a reducing agent. The setup, which went into production at MTU in the first half of 2023, is the only one of its kind in the world.

Starting in 2026, MTU also plans to use newly developed ECM equipment to machine the profile grooves of low-pressure turbine disks as an alternative to the conventional broaching process.

Efficient processing: Because the tools make no contact with the component, they experience virtually no wear and tear and leave no machining marks on the component.