innovation

Automated airfoil production paves way to the smart factory

MTU has developed an automated airfoil production process that operates autonomously for up to 66 hours and will now provide the basis for larger smart factory projects.

author: Tobias Weidemann | 5 mins reading time published on: 09.03.2022

author:

Tobias Weidemann

has been working as a journalist and content consultant for more than 20 years. He writes about technology and business topics, often with a focus on business IT, digitalization and future technologies.

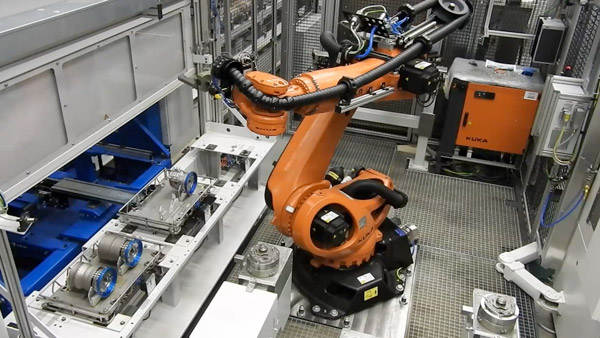

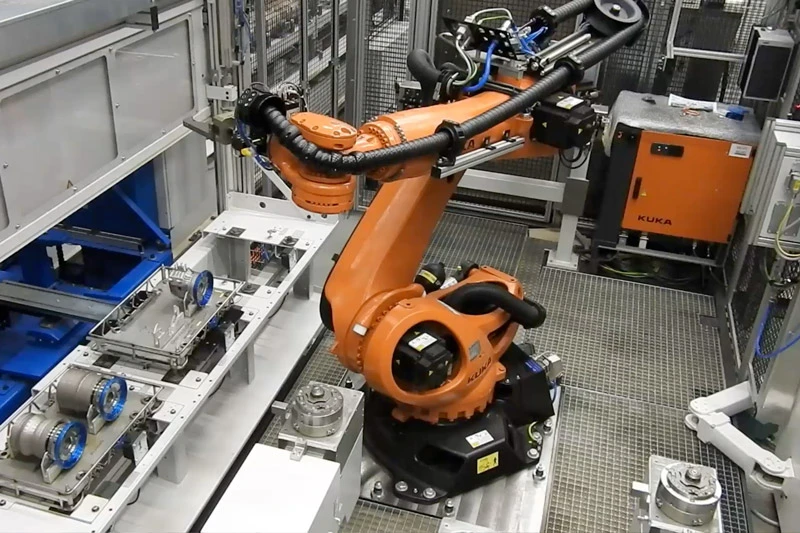

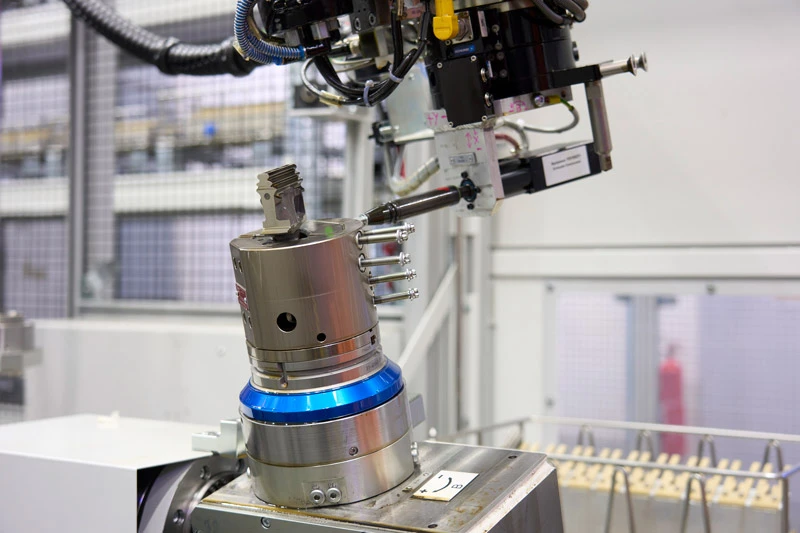

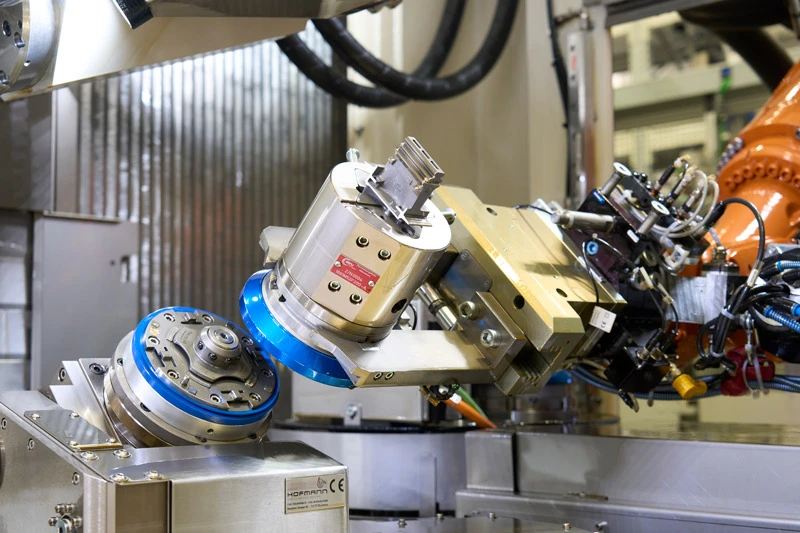

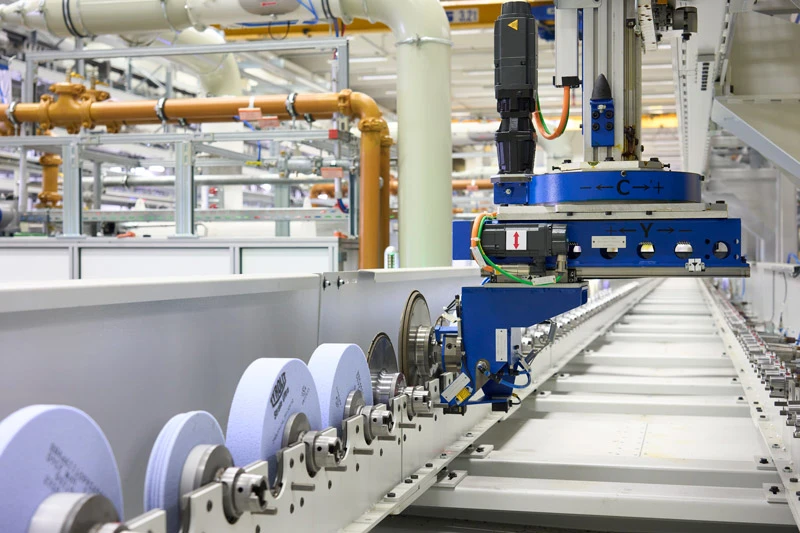

The robot places a blank in the clamping device, secures it with numerous screws, and loads it into one of the five tool machines. The machines drill and mill, grind and gauge—everything is fully automated, a value creation process that appears to be guided by an invisible hand. And it’s efficient: while the machines are hard at work, the robot is already attending to the preparation and post-processing of the next parts and tools. “With the new system, we have proven that Industry 4.0 meets the requirements of even the extremely sophisticated high-tech production of engine parts,” says Christiane Müller, Head of High-Pressure Turbine Guide Vanes at MTU Aero Engines, describing the new flexible manufacturing system (FMS). For the connected production of rotor blades, guide vanes, and structural components, this marks an enormous leap toward the smart factory. Assisted by a control system, the facility’s five tool machines manufacture components in parallel, working flexibly and, above all, autonomously for days at a time without human intervention. “And they take up just a third of the space needed for conventional production in the past,” Müller adds.

Fully autonomous production over the weekend

Six potential work systems were for the taking—but rather than modernizing its existing production, MTU wanted to take manufacturing to the next level with state-of-the-art, progressive automation. So the company chose to go with a production unit that can work autonomously for as long as possible. “66 hours—this is the exact amount of time it takes to comfortably bridge a whole weekend,” says Marc Weiß, FMS Project Manager. And that’s how long the flexible manufacturing system should be able to operate without human intervention. The machine’s built-in autonomous correction function and extensively planned preventive maintenance ensure the necessary process stability. This sets the stage for even more efficiency gains in the future.

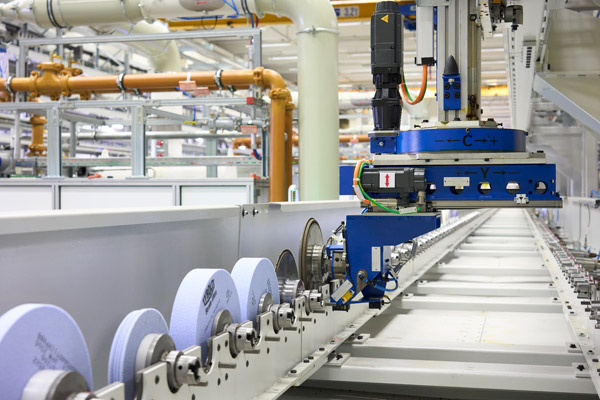

Employees still have to mount and subsequently remove grinding wheels and other tools by hand—95 percent of the work steps required to manufacture turbine blades involve grinding. But drill bits and milling cutters are automatically switched out and gauged by the robot cell.

From 7 hours to 15 minutes: downtime reduced

This system has also made the order processing side of production a lot more efficient and flexible—a welcome development, given how the general trend seen in recent years of producing increasingly smaller batch sizes and enabling the extensive tailoring of customer orders hasn’t stopped at turbine blade production. Although production may not have been reduced to a batch size of one in practice, orders are usually placed for batches of between 70 and 120 workpieces. And with the new system, these batch sizes can be reduced further without incurring high retooling costs.

15 minutes

instead of 7 hours:

downtime significantly reduced

66 hours

autonomous production:

whole weekend bridgeable

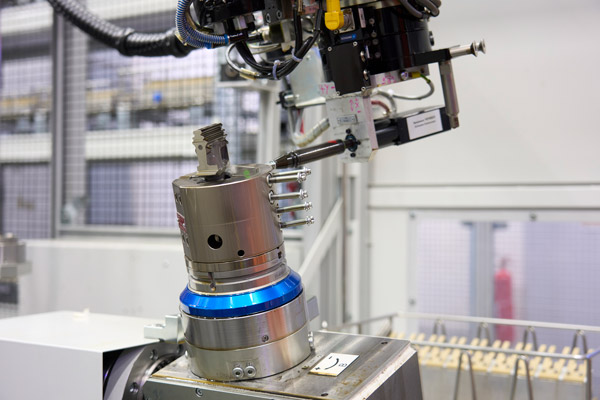

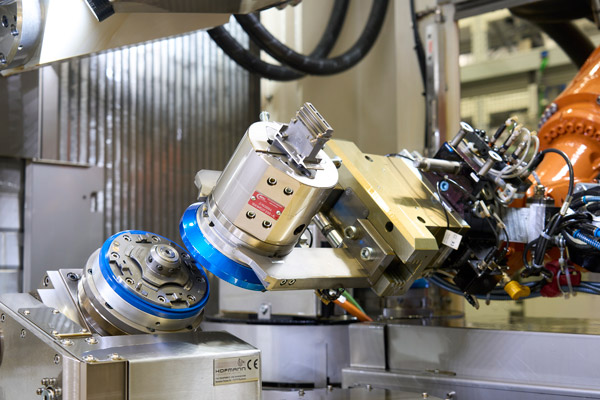

A double structure is in place here to keep downtime to a minimum. For example, one milling cutter is used in the tool machine while another is being prepared for the next step. The same goes for the robot cells: a component is clamped in place on one fixture while a processed component is removed from another before a new blank is mounted. “This means we can plan orders more flexibly and we don’t have to worry so much about retooling times—on balance, our production is more efficient in several respects,” Müller says. While conventional production lines had previously needed between seven and eight hours for retooling, the new system is ready to go in just 15 minutes.

It certainly took a lot of time and effort to reach this stage of flexible manufacturing: “But by the same token, we’ve benefited from a successful, if steep, learning curve,” Weiß says. Continuing to run the old system while setting up the new one proved to be particularly challenging logistically. Then, in July 2021, the FMS was able to move into the final stage of the project, with its five tool machines and fully automated processes. “Additional components are currently being coordinated for FMS production to ensure it is completed and goes into full operation by the end of 2022,” Müller says.

Pioneering production of engine parts

“This has essentially become a lighthouse project, not just for MTU but also for the wider industry. We’ve never seen an automated production system like it anywhere in the world, especially not for this type of component or extremely sensitive manufacturing situation,” Weiß says. The high level of in-house knowledge that has gone into the project is certainly a first: for one thing, MTU programmed the tool machines itself; for another, even the clamping station with its robot-operated screw fitting is an element that was specially developed by MTU. The company’s work on the tool changing cell was also groundbreaking. Together with its partners, MTU devised and developed solutions that didn’t yet exist in the same form, not even in other industries. Müller also emphasized the importance of the expertise offered by the company’s employees, who were able to draw on their experience of conventional systems. “Incorporating this knowledge into the new system means that it, too, represents a balanced partnership between humans and machines.”

The flexible manufacturing system (FMS)

A step-by-step guide to autonomous production

FMS as a blueprint for bigger digitalization projects

The system may have gone live, but the FMS chapter is far from complete. There are plans to build another, much more extensive production facility at MTU’s Munich site in the future—essentially based on the same concept and with production equipment from the same manufacturer. “All of this creates a blueprint for other systems, which will emerge over the next few years on a much larger scale and take up an entire hall,” Weiß says.

The “Improvement & Digitalization” cross-functional department set up last year pools, among other things, ideas and topics related to the smart factory. Fabian Lindermer, who is responsible for the area of digitalization, is confident that the flexible manufacturing system, with its high level of automation, is a valuable element on the road to digitalizing production at MTU. “In the future, we as MTU will connect the many individual initiatives we have relating to smart systems in assembly or production and link them to an overall digital system—transforming island solutions into a truly smart factory.”