innovation

MTU industrializes ceramic milling

MTU employs a new ceramic-milling technology in manufacturing the GE9X turbine center frame. The frictional heat just flies away with the chips.

08.2018 | author: Thorsten Rienth | 3 mins reading time

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

Whenever Alexander Steurer wants to see how the youngest offshoot of the MTU technology family is doing, he doesn’t have far to go: out the office, down the center aisle of the nearest manufacturing hall, a right turn into the corridor, up four steps. And there it is—right in front of him is the MCM Clock 1800, the new machine for an equally new technology: ceramic milling. In this kind of milling, the cutters are made of ceramic, not carbide.

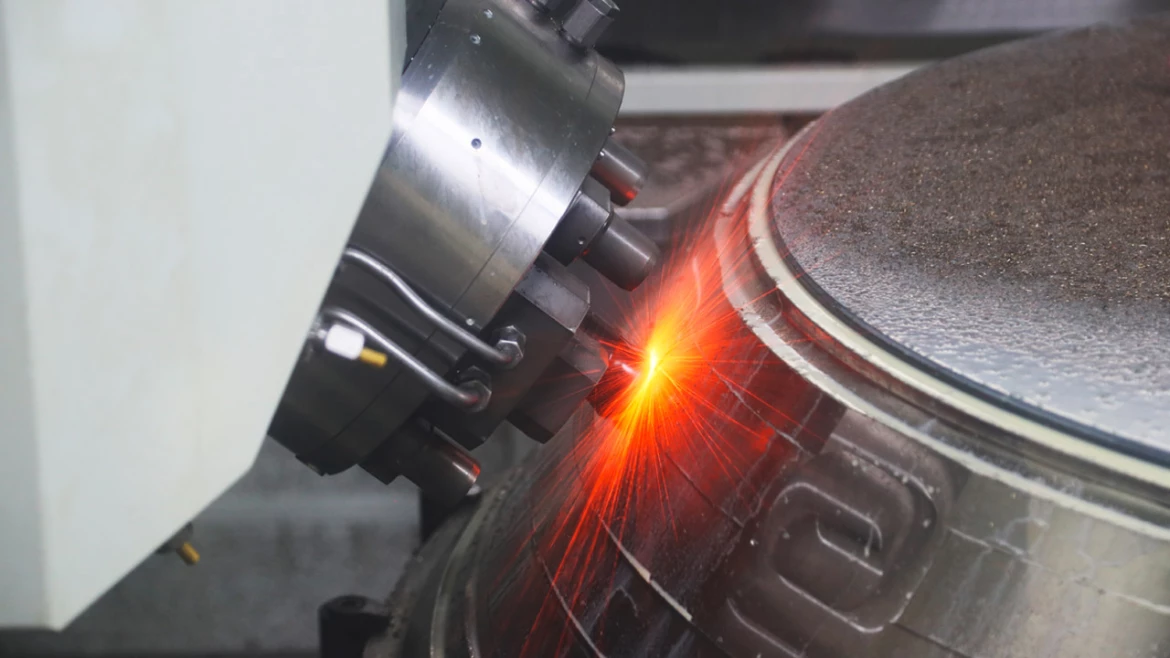

At MTU Aero Engines, Steurer heads NC programming for frame construction—that is, creating software to run the manufacturing machinery. He indicates the bright orange dot between the milling head and the GE9X turbine center frame (TCF). “Almost 1,200° Celsius,” he says. “That’s pretty damn hot.”

In conventional production methods, this is precisely what engineers are doing their best to avoid, but in ceramic milling, it’s the whole point. Inconel 718, a nickel-chrome superalloy, has to be heated to a high temperature for it to change from a superhard material into one that is soft and malleable. “Then the milling head can literally tear the material out.”

In dozens of tests, the NC programmers developed special sequences of entry and exit movements.

Cooling included

What’s the point of this brutal process? As the dough-like chips fly away from the part being milled, they take the heat with them. And that is a vital feature: “Cooling lubricants would be counterproductive here and lead to thermal shock,” explains Steurer. The temperature of the part is moderately reduced solely through the air-cooled spindle, starting from the end of the part that is not currently being milled.

Steurer’s team has been researching this method since 2013, but they didn’t procure the MCM Clock 1800 until last year. Finally, they had a machine that could deliver the breakthrough. Its spindle reaches speeds of up to 14,000 revolutions per minute. Ceramic plus Inconel 718 plus speed—all three combined produce the necessary amount of heat. The machine’s predecessor was only able to do somewhat more than 4,000 rpm.

In dozens of tests, the programmers developed additional special sequences of entry and exit movements. Their goal was to figure out the optimum combination of forward feed, approach path, revolutions, and depth of cut. “I don’t think there’s anyone else in the world who has tested this as thoroughly.”

Altered milling process

Frictional heat requires changes to the individual milling steps. “Normally you would process a frame in one go,” explains Stefan Gremminger, one of the NC programmers on Steurer’s team, “but that doesn’t work with ceramic milling.” If an operator tried to mill adjoining sections one right after the other, that would stretch the material too much. The circular center frame would become slightly egg-shaped, and even if the eye can’t see it, the distortion would have a dangerous impact on measurements that have to be painfully accurate. Although MTU uses this technique only to process the approximate shape, tolerances are still measured in just tenths of millimeters. “That’s why after every pass with the milling cutter, we rotate the part another 60 degrees,” Gremminger says. “It takes time—but the higher milling speed more than makes up for it.”

So far MTU has produced upwards of ten GE9X turbine center frames with the new technology, most recently including the first flying parts for the Boeing 777X. The aircraft’s maiden voyage is scheduled for 2019, with the first models to be delivered to customers a year after that.