people

Engine Experts

Die MTU fliegt bei der Digitalisierung nicht nur am Puls der Zeit – mit innovativen Ansätzen und neuen Anwendungen gestaltet sie den Wandel ganz konkret mit. Sechs Projekte, die schon weit fortgeschritten sind.

author: Thorsten Rienth | 2 mins reading time published on: 01.05.2019

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

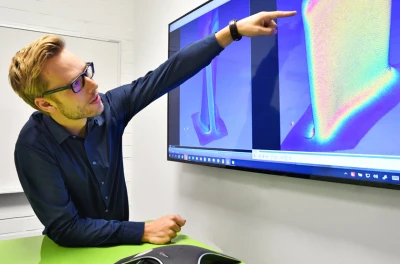

Sometimes all it takes to understand complex interrelationships is a simple image: in the future, passengers will still board real aircraft powered by real engines. However, the development and production of these engines is increasingly shifting to the digital world. Having anticipated this trend early on, MTU benefits – especially right now – from the fact that Skype meetings and video conferences, for example, have been an established part of its business for some time. Thousands of employees may be temporarily working from home, but they are still there to help colleagues, customers and business partners.

Back in 2016, MTU began rolling out its Digital Transformation Program across the board. The goal was no less than to digitalize the entire company. Four years later, MTU is driving forward some 300 individual digitalization projects. Needs and solutions fit hand in glove.

In its most basic form, the approach spans departments – and often sites as well. It includes ensuring on-time deliveries, minimizing inventories and presenting product progress – alongside the widespread rollout of data analyses, machine-learning algorithms and artificial intelligence. Digital models on computers are increasingly used to simulate costly and time-intensive testing. Networked customer and supplier data mitigate potential disruptions in the supply chain – long before they can jeopardize the company’s sophisticated production logistics processes.

The approach is also firmly anchored in the administrative departments, where it goes far beyond replacing the use of paper by electronic workflows. Robotic process automation supports standard processes, while the new e-learning system provides independent study programs and supports blended learning in the workplace. It’s about having the courage to challenge current processes and think about them critically. The same logic applies to the future tools themselves. After all, digitalization is not an end in itself. Our focus is always on real added value that helps us and our products make measurable progress.