people

Digital tools help create new, efficient components

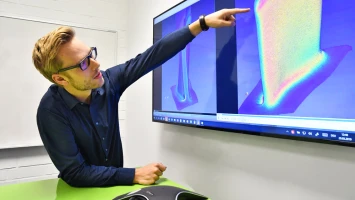

Dr. Urška Zore programs 3D tools that MTU developers use to design even quieter, more fuel-efficient engines.

author: Thorsten Rienth | 3 mins reading time published on: 04.05.2020

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

Although this COBRA does not bite, it does need to be fed—on mathematical and geometric methods containing functions that, if written out, would stretch for several meters in some cases. Filled with variables, three-dimensional objects such as engine blades form on engine developers’ screens. The meter-long function defines in high resolution every point of the object in three-dimensional space.

- Using multiphysics simulations to boost efficiency

- A data scientist for the aviation industry of tomorrow

- Digitalization paves the way for predicting tool wear

- Managing digital transformation

- Digital tools help create new, efficient components

- Talking geometries: A common language for more efficient engine development

COBRA stands for COnsistent Blade Representations for Aircraft engines. It is MTU’s own in-house software for generating the geometries of engine components. This subject takes up most of Dr. Urška Zore’s working day.

Without fear of exaggeration, we can say that the COBRA software is a mainstay of MTU engine design. After all, the design intricacies in modern engines that make the difference as regards extra efficiency and service life are becoming increasingly detailed, particularly when it comes to aerodynamics and structural mechanics.

“The greater our geometrical expertise, the faster we can develop new designs that go beyond the industry standard,” Zore explains. By geometrical expertise, she means being able to mathematically model all three-dimensional shapes that can conceivably arise in an engine.

The 31-year-old joined MTU after studying mathematics in Ljubljana, Slovenia and then doing a PhD in Linz, Austria. Initially, she came to MTU as part of an EU research project, but at the end she received an offer to stay on.

Zore carries out most of her work behind the scenes. In the development of engine parts or modules, this background work is vitally important: “It’s all about providing developers with the best possible 3D tools so that they can design the best possible engines,” she says, describing her role. “Our colleagues tell us what they need and we think about the mathematics we can apply to meet their requirements. And then we work together to create future-oriented solutions.” The subject is very complex, as practically all technical disciplines are involved in the processes and are relevant for the tool in their own specific way.

For that reason, the snake image is appropriate in this regard as well. The COBRA software is not static: it moves. “Together with my colleagues, I program new digital tools, integrate them in COBRA, and take care of support side,” the IT planner explains. The quality of the digital models is key, stretching all the way from the new digital tools to the finished component; and from the scanned finished component back into its digital 3D representation.

In all of this, she never loses sight of the big picture. “The greater our geometrical expertise, the faster our developers can create the new designs.” In turn, this ultimately means engines that carry aircraft through the air even more efficiently and quietly and with even lower emissions. With a wink, the mathematician explains one of the many new things she has picked up in the whole process: “In addition to Slovenian, English, German and a few programming languages, I’m now also learning to speak the language of engineers.”