aviation

Low-pressure turbines: The path to world-class manufacturer

A journey that dates back 45 years: MTU is now a world-class manufacturer of low-pressure turbines—and its high-speed, high-end version for the Geared Turbofan™ is unmatched.

author: Denis Dilba | 7 mins reading time published on: 01.04.2019

author:

Denis Dilba

holds a degree in mechatronics, is a graduate of the German School of Journalism, and founded the “Substanz” digital science magazine. He writes articles about a wide variety of technical and business themes.

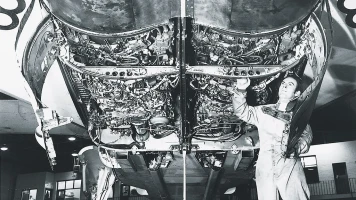

What was MTU’s first step on the path to becoming a leading manufacturer of low-pressure turbines? Surprisingly, it was the development of an exhaust casing. Exactly how this happened is something Ludwig Schweikl knows firsthand, because he and his colleagues were the ones who built it. “At that time, the early 1970s, corporate management made a strategic decision to get into the commercial engine business,” says Schweikl, who had a long tenure as head of design at MTU. The experts already had experience with military engines and had developed and built the intermediate-pressure turbine for the RB199, the engine for the Tornado. Over the course of this production process, MTU came into contact with American engine manufacturer Pratt & Whitney. “Somehow this led to an invitation for the MTU development department to visit the Pratt headquarters in East Hartford,” the engineer recalls. It would be a great way to get to know one another, said the Americans. Sounds good, responded the Germans. So, Schweikl soon found himself on a plane making its way to the US and was thus the first MTU developer to meet his counterparts at Pratt & Whitney.

- RB199 development: the engine that started it all

- Low-pressure turbines: The path to world-class manufacturer

- Blisk development: How blade and disk became one

- Geared Turbofan: How the engine of the future was developed

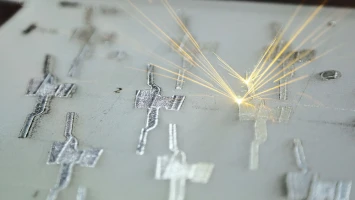

- Additive manufacturing: Printing a component, layer by layer

“They were very skeptical as to whether or not we had anything to offer. At that time, Pratt & Whitney was the world’s leading engine manufacturer and MTU was just a small company,” the 82-year-old says. But he made a good impression, and MTU was asked to try its hand at the exhaust casing for a new version of what was then the classic medium-haul JT8-D. The collaboration worked smoothly, far exceeding Pratt & Whitney’s expectations. MTU’s skilled engineers impressed the American engine manufacturer—which then asked them to develop the low-pressure turbine for the JT10-D: a larger, more powerful follow-up to the JT8-D. It was an honor and an order that Schweikl and his developer team gratefully received. “This marked the beginning of the low-pressure turbine business for MTU,” Schweikl says. Thus began a true development race, with one innovation topping the other—a race that continues to this day.

Experts share the word about MTU’s competence

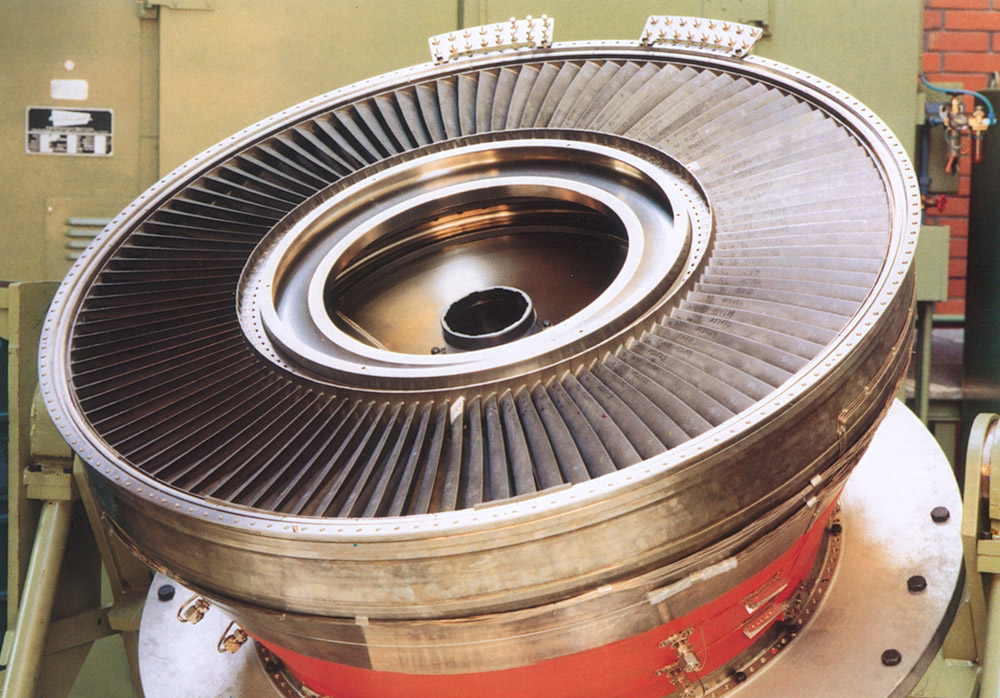

The first low-pressure turbine for the JT10-D, soon renamed the PW2000, made a shining impression thanks to a special technical refinement. As the amount of thrust changes, rotors and engine casings expand and contract at different speeds. This can lead to greater clearances and in turn to performance losses. To combat this problem, the engine incorporated the first solution for cooling the casing, called the active clearance control (ACC) system. This offset the difference in the thermal expansion of the components, thus reducing clearance and considerably improving the efficiency of the entire assembly. Pratt & Whitney contributed the idea and the patent, while MTU made it a reality. “Today it is standard in every engine,” says Schweikl.

Word about MTU’s expertise in low-pressure turbines spread throughout aviation circles. As a result, a short time later Schweikl and his team also took on the development of the low-pressure turbines for the V2500 program. A low-pressure turbine has a major influence on an engine’s overall performance. With the V2500, which powers the A320 family and has become one of the most important programs in MTU’s commercial portfolio, the engineers systematically applied what they learned with the PW2000. This meant they could significantly improve the efficiency of the low-pressure turbine for the V2500.

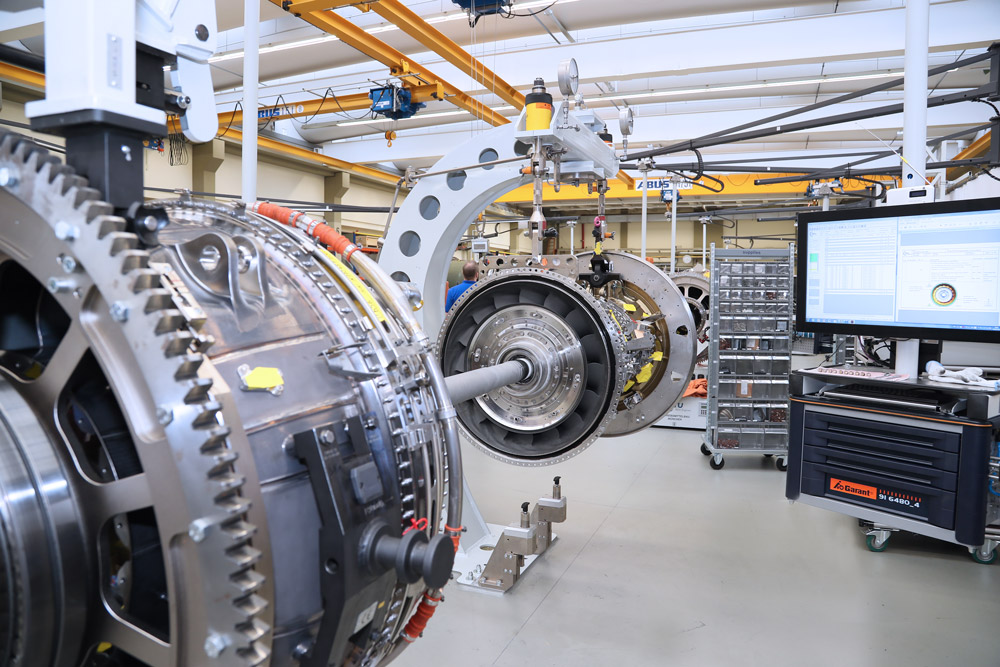

Just three stages in the high-speed low-pressure turbine

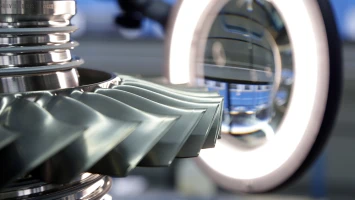

Many more MTU low-pressure turbines followed: they are found in business jet engines, in the power turbines of turboshaft engines for heavy-lift helicopters, in turbofan engines for medium- and long-haul airliners, and even in the GP7000 for the Airbus A380 megaliner. MTU has numbered among the global elite in low-pressure turbine technology for a long time now. The Munich company’s current masterpiece is the high-speed low-pressure turbine for the Geared Turbofan™ (GTF): optimizing the aerodynamics down to the smallest detail has achieved a higher degree of efficiency. At the same time, the high rotational speeds that result from the GTF’s reduction gearbox mean the stages work harder. That’s why the pressure turbine module in the A320neo engine needs just three stages. As a result, space, weight, maintenance costs, not to mention fuel consumption and therefore CO2 emissions all decrease.

And as if this weren’t impressive enough, the new turbine is also much quieter than conventional models. Its noise emissions are at higher frequencies that are better absorbed by the atmosphere, to the point where the human ear can barely detect them. With this world-class low-pressure turbine, a key component without which the GTF would not exist, MTU today has moved into a league of its own. But even this exceptional turbine has room for improvement, through new materials, powerful computer simulations, and newly optimized aerodynamics. MTU engineers are currently working at it—and in doing so, they will write the next chapter in the extraordinary story of the low-pressure turbine’s development.