good-to-know

Boeing 777X – the largest twin-engine jet in the world

In January 2020, the new Boeing 777-9 powered by GE9X engines took to the skies for the first time. Entry into service is scheduled for 2027.

author: Thorsten Rienth | 3 mins reading time updated on: 02.02.2026

author:

Thorsten Rienth

writes as a freelance journalist for AEROREPORT. In addition to the aerospace industry, his technical writing focuses on rail traffic and the transportation industry.

- Boeing 747: Queen of the Skies

- The Boeing 737: How a simple jet revolutionized aviation

- Airbus A400M – modern military transporter and all-around talent

- Airbus A220 – The innovative medium-haul jet from Canada

- Boeing 777X – the largest twin-engine jet in the world

- Airbus A321XLR: A new chapter for aviation

- The Airbus A380 – the world’s largest passenger aircraft

- Airbus A319 – a small aircraft for a wide range of tasks

- Airbus A320 – a medium-haul bestseller for almost 40 years

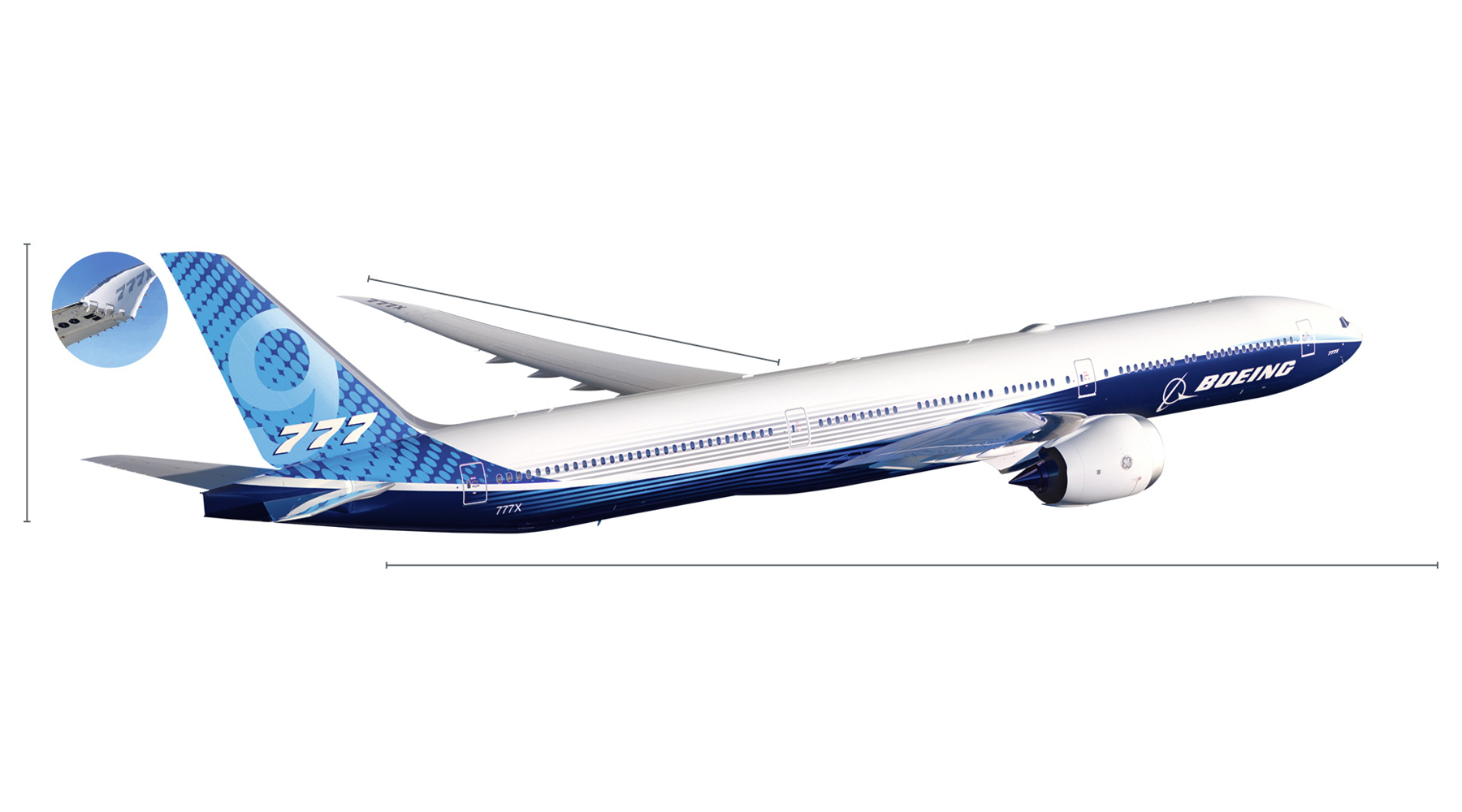

The Boeing 777X redefines the future of long-haul travel. As a modernized evolution of the renowned 777 family, it combines state-of-the-art technologies with enhanced efficiency and impressive performance. The 777-9, the world's largest twin-engine jet, offers unparal-leled passenger capacity, while the shorter 777-8 excels with its exceptional range of over 16,000 kilometers. A distinctive feature of the 777X is its innovative folding wingtips, which enhance aerodynamic efficiency and facilitate airport operations by reducing wingspan on the ground.

In terms of passenger comfort, the 777X sets new standards. The cabin is designed with modern principles, offering larger windows, a wider cabin, and improved air quality, result-ing in a more pleasant flight experience.

The 777X is powered by the advanced GE9X engines, with MTU Aero Engines playing a sig-nificant role in their development. The first flight of the Boeing 777X with GE9X engines took place on January 25, 2020, marking a crucial milestone toward commercial readiness.

The initial delivery of the Boeing 777X is planned for 2027, poised to significantly influence the aviation industry with its innovative technology and enhanced efficiency.

The Boeing 777X: Facts and figures

- The folding wingtips reduce the wingspan on the ground from 71.75 to 64.82 meters—taking it below the critical 65 meter mark and enabling the 777X to fit into “normal” airport gates.

You may also be interested in following content

Boeing's 777X – The GE9X Engine, Wings and Fuselage

Take a look at what defines the Boeing 777X.

-

Adding length to the CFRP wings also makes sense from an aerodynamic perspective: Boeing says this improves the lift-to-drag ratio and increases the fuel efficiency in cruise.

-

The interior of the 777X is inspired by that of the Boeing 787 Dreamliner. But the 777X has added selling points that include an even quieter cabin and higher levels of humidity—the latter improving the air quality in the cabin for passengers.

-

The Boeing 777-9 is the world’s longest twinjet, featuring a fuselage that measures 76.72 meters.

-

Boeing gives the aircraft range as 7,285 nautical miles for 426 passengers in a two-class configuration. This is equivalent to nearly 13,500 kilometers. At 69.79 meters, the slightly shorter 777-8 can fly for an even longer range of 8,730 nautical miles (16,170 kilometers) with 384 passengers on board.

-

The 777X is powered by two GE9X engines, each equipped with an 11-stage high-pressure compressor that delivers a pressure ratio of 27:1. The engine’s overall pressure ratio is 60:1.

-

In the summer of 2019, the GE9X set a Guinness World Record as the most powerful commercial aircraft jet engine: under test conditions, the engine reached 134,300 pounds of thrust—appreciably higher than the previous record holder, the GE90-115B, which delivers 127,900 pounds of thrust.

-

According to GE, the GE9X consumes ten percent less fuel than the GE90-115B, the engine that powers the Boeing 777-300er.

GE9X

GE9X

- Max. thrust:

- 134,300 lbf

- Bypass ratio:

- 10:1

- Pressure ratio:

- 60:1

- Fan diameter:

- 3,4 m

- Fuel consumption:

- -10% (compared to previous version)

Engine for the Boeing 777X-9: GE9X

MTU Aero Engines is a four-percent shareholder in the GE9X program, – assuming development and production responsibility for the turbine center frame (TCF).

For MTU, the engine provides a firm foothold in today’s cutting-edge generation of widebody aircraft. The TCF is one of the most sophisticated components in the commercial engine business: exposed to extreme stresses, it serves a duct for the hot gas flowing from the high-pressure turbine past structural components and cables to the low-pressure turbine at temperatures of up to 1,000 degrees Celsius—with minimum aerodynamic losses. MTU has many years of experience with this module, which it also develops and produces for the GP7000 (Airbus A380) and the GEnx (Boeing 787 Dreamliner, 747-8) engine programs.

The GE9X engine from General Electric (GE) represents the latest generation of propulsion systems for long-haul airliners, specifically the new Boeing 777X widebody aircraft.