innovation

Innovative assembly system for the EME Aero MRO shop

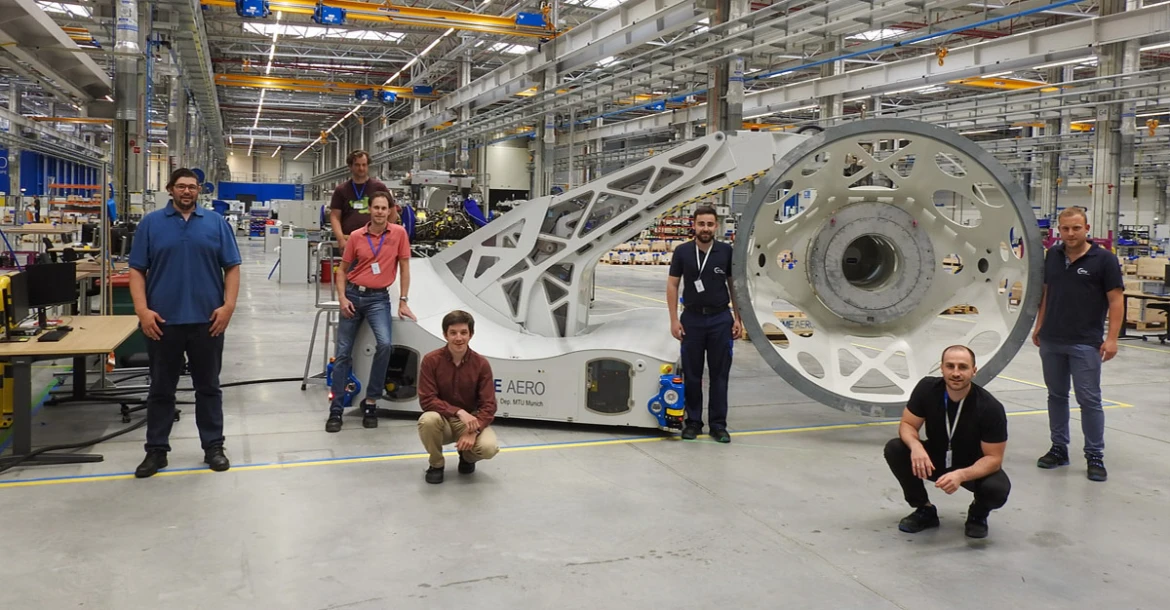

MTU specialists in Munich have rolled out a unique, high-tech assembly concept for EME Aero’s MRO shop.

author: Nicole Geffert | 6 mins reading time published on: 07.07.2021

author:

Nicole Geffert

has been working as a freelance journalist covering topics such as research and science, money and taxes, and education and careers since 1999.

There were one or two sleepless nights, that’s for sure. This was inevitable given the enormous time pressure and magnitude of the task in hand. EME Aero is a joint venture between Lufthansa Technik and MTU Aero Engines with a shop located in Jasionka near Rzeszów, Poland. The shop was given just three years in which to develop and roll out an entirely new, high-tech assembly concept that would ensure top-class maintenance for Pratt & Whitney GTF™ engines.

This mammoth project was the perfect job for the specialists from MTU’s production and facilities service in Munich. “We’d previously helped develop a unique GTF final assembly line at MTU in Munich, and we’d already thought up and sketched out ideas for an innovative assembly concept for Maintenance,” says Stefan Hofner, Production Resources Architect at MTU, speaking on behalf of the whole team. The project team is made up of colleagues working in many different disciplines and departments. “This interdisciplinary collaboration enables us to complete such a project within the short timeframe required,” Hofner says.

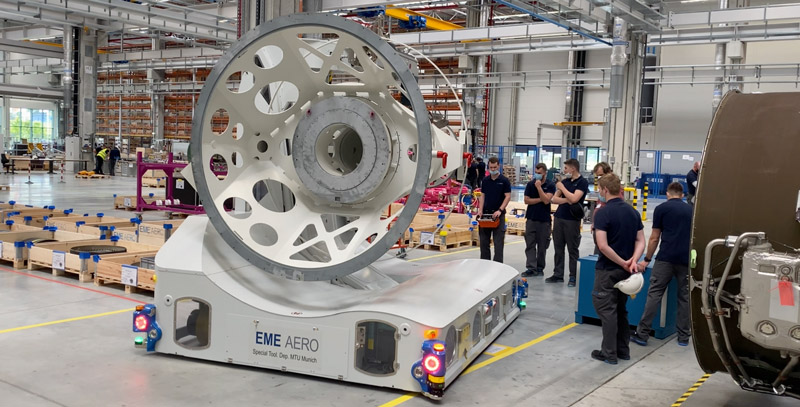

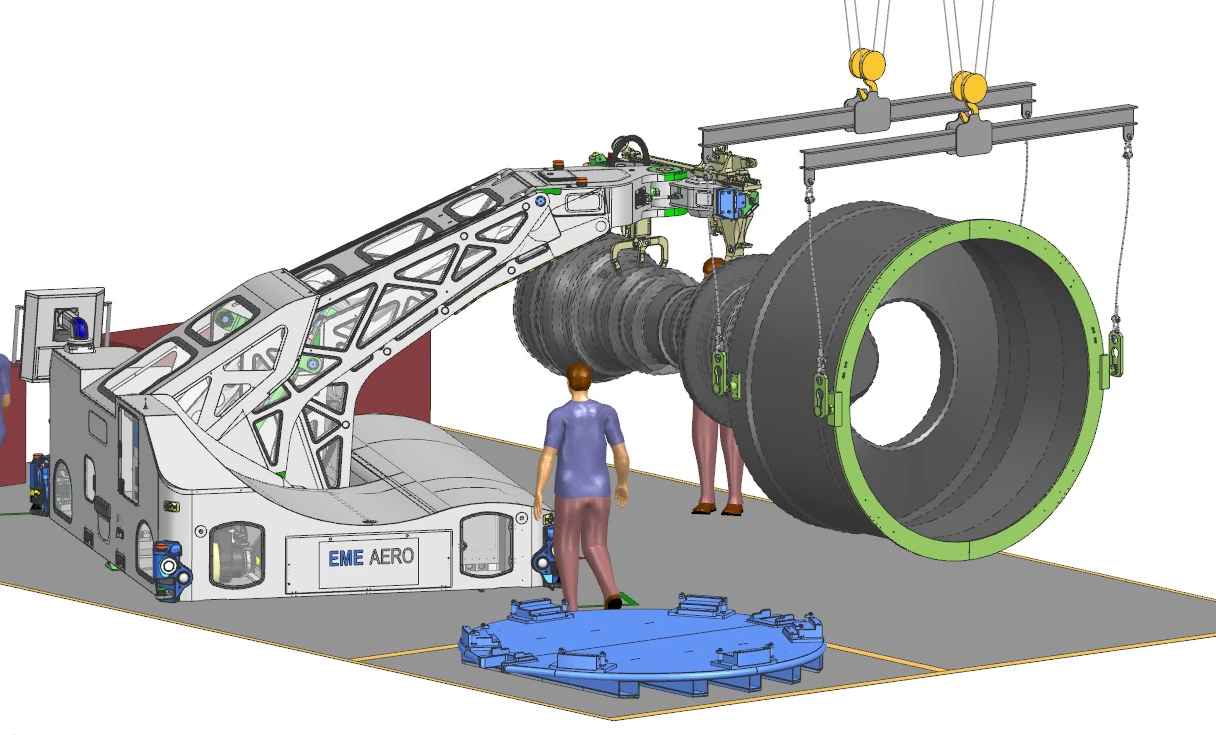

High-tech assembly concept: In record time, MTU specialists developed an assembly concept for maintaining geared turbofan engines in EME Aero’s MRO shop.

Thanks to their innovative concept, the MTU experts won the contract and set to work. “When planning an MRO shop, the key question is always what to move: the engines or the tools and staff?” Hofner explains. This question is about establishing the guiding principle for the shop—either the engines pass along an assembly line or are maintained at a single station known as an engine dock—and there are always different ways of tackling it. It also depends on how many engines are to be maintained each year, as the line approach lends itself well to a large number of shop visits for engines with the same design. “But EME Aero didn’t have to decide between an assembly line and individual engine docks. Our assembly concept offers the shop the flexibility that stems from being able to have the best of both worlds,” Hofner says.

No disturbances in the overall flow

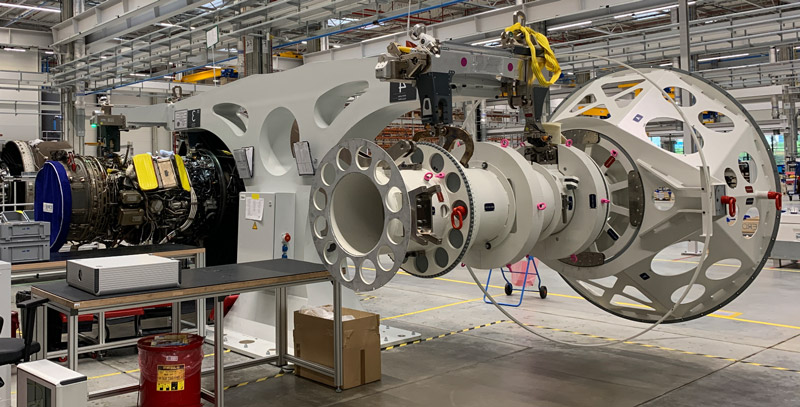

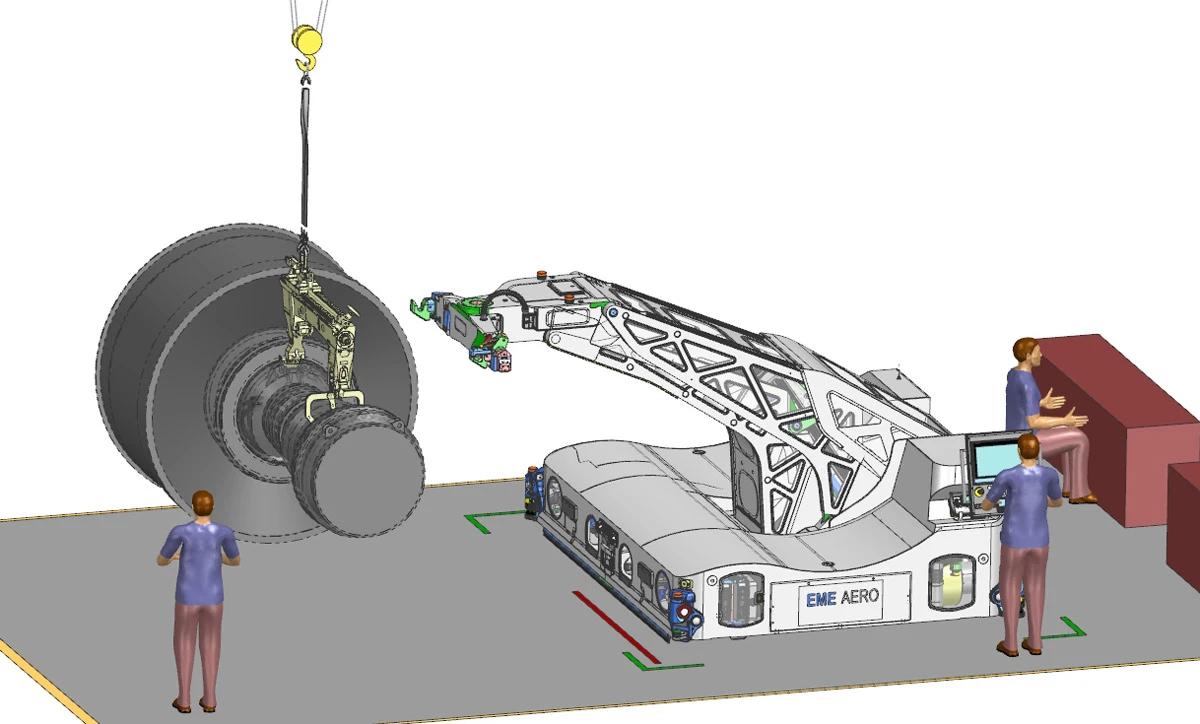

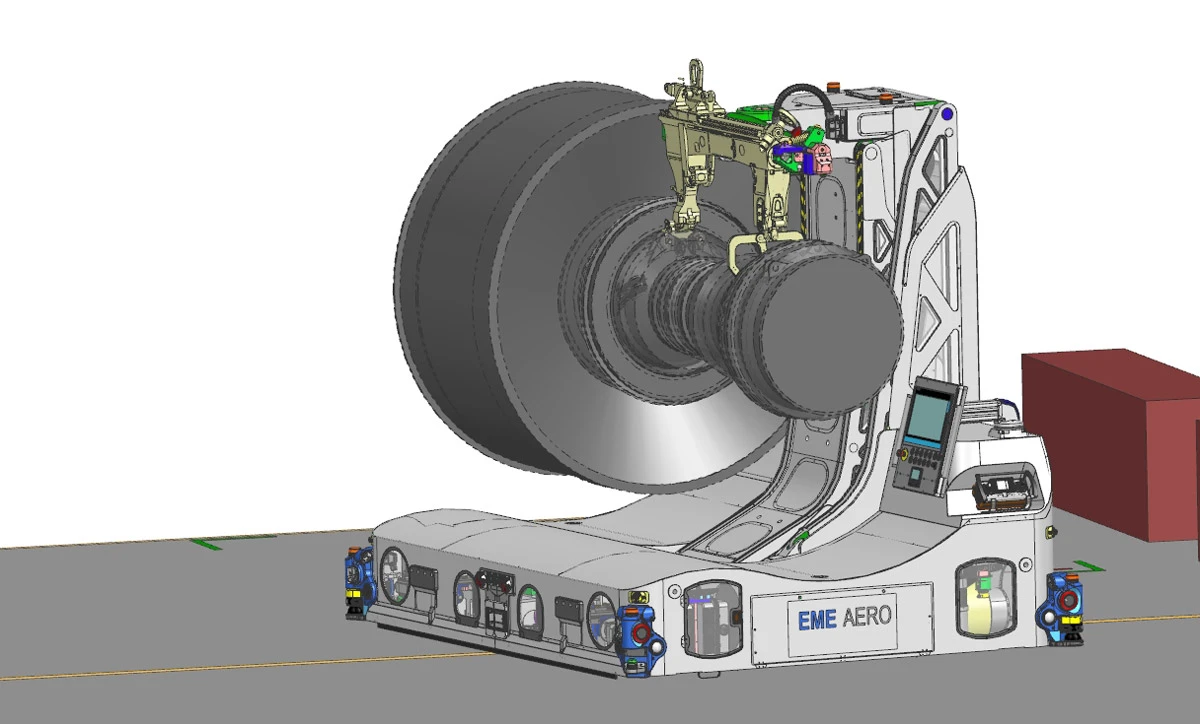

“Flexibility” is the key word. Unlike a traditional flow line, the assembly system designed by the Munich project team isn’t based on stationary structures such as those found in the overhead engine suspension systems typically used in MRO operations. Instead, the engines are fitted to freely moving, floor-based carriers that can be pulled in and out of the production line without disturbing the overall flow. At the heart of the concept are two systems: the mobile transport and overhaul system (MTOS) handles the complete teardown of engines along the flow line, while partial disassembly is performed in the stationary dock of the fixed overhaul system (FOS).

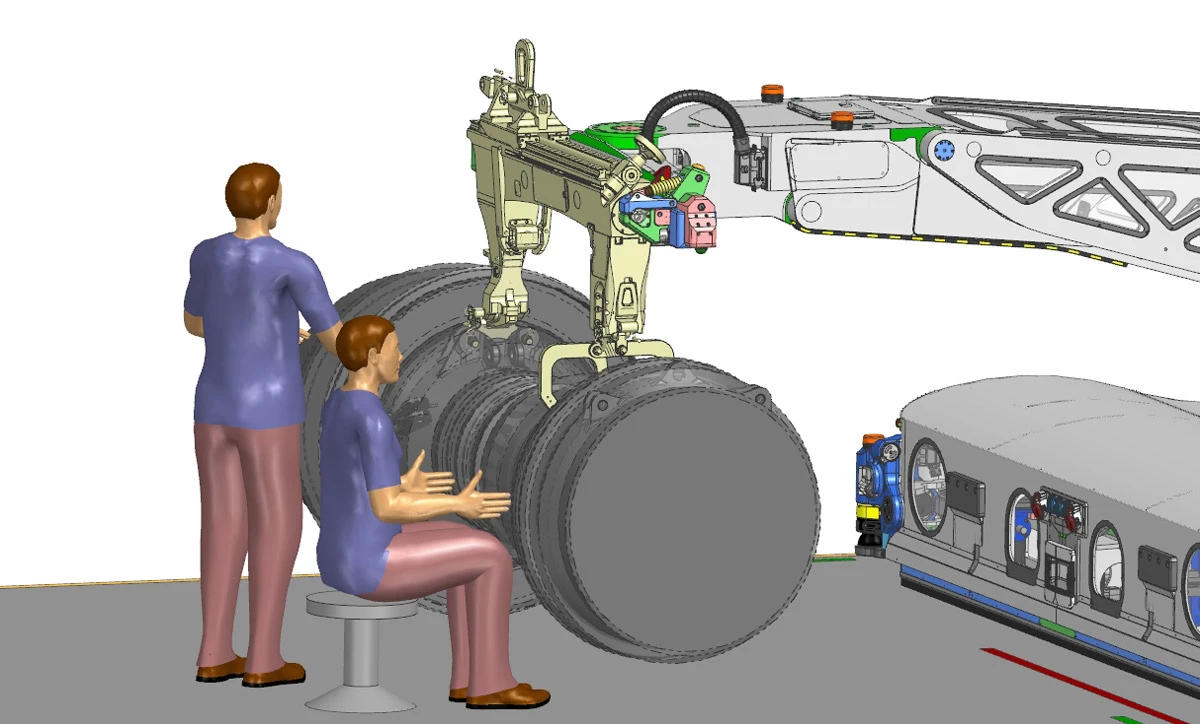

“The MTOS is made up of a remote-controlled cart that moves the engine from one station to the next and puts it into an ergonomic position,” Hofner says. “At each station, the right tools and the specialists required for the next work step are ‘waiting’ for the engine to arrive. This is a very efficient setup for when the shop is busy.” Then when the FOS comes into play, the engine remains at the same station: the dock. “Staff are deployed as needed and the tools they require are brought over to them. The FOS is ideal for situations involving small batch sizes or smaller, more specialized repairs.”

“Since the stationary FOS uses the same interface as the mobile MTOS, the engines can switch flexibly between the two systems. This standardizes processes and saves time.”

Production Resources Architect at MTU

Increasing flexibility and standardizing processes

As soon as a GTF engine arrives at the EME Aero shop, an indoor crane attaches an assembly carrier to the engine. These assembly carriers, also known as shuttles, are at the heart of the concept and function much the way adapters do. They let the crane lift the engine either into or out of the assembly systems in all stages of its construction. In other words, the shuttles are the interface between each engine and the MTOS or FOS. The engine can now be easily mounted or disassembled, ready for numerous work steps with no need for any further rerigging. “Since the stationary FOS uses the same interface as the mobile MTOS, the engines can switch flexibly between the two systems,” Hofner says. “This standardizes processes and saves time.” For example, if the scope of work being performed on the FOS increases, the engine can be switched to the MTOS without a problem.

Accessing components from all sides

Since the EME Aero shop is an entirely new building, the MTU project team didn’t have to contend with any architectural limitations or existing structural elements. The facility also has a clearly defined engine portfolio. Specializing in the maintenance of GTF engines, EME Aero already handles the PW1100G-JM and by the end of the year will also have everything in place to maintain, repair and overhaul PW1500G engines. Here, too, the MTU specialists planned ahead.

Their assembly system can be adapted for the entire GTF family. This means that a PW1500G doesn’t have to be put through an assembly system custom-built for that engine type, but can also be processed on the assembly line used for the PW1100G-JM. The team therefore developed individual shuttles for the different GTF engines. “This is because the location of the suspension point varies from engine to engine,” Hofner explains. Engines are always suspended from a central point at their core, which allows modules to be fully assembled or dismantled without any further assistance. The individual shuttles make it possible to implement standardized work processes at all stations, regardless of what type of engine is being worked on. Since the engines are suspended, the mechanics and their tools can access the components they need to work on from all sides. They can also adjust the height of the MTOS, which makes for an ergonomic setup.

In addition, the MTU project team developed some technical highlights for assembling the modules. At what are known as turning mounts, the mechanics can position the modules so that they can work most effectively. Since the turning mounts are battery-operated, there are no cables to get in the way. Even the central tooling equipment in the module area is designed for working on both the PW1100G-JM and the PW1500G.

“This dual approach offers advantages that benefit MTU and its customers.”

Production Resources Architect at MTU

How did the team manage to roll out its concept in just three years? “In our line of work, people generally specialize either in traditional plant and mechanical engineering or in engine assembly. As MTU’s tool engineering department, we cover both these key areas of expertise,” Hofner says. “This dual approach offers advantages that benefit MTU and its customers.”

At the moment, the assembly concept for EME Aero’s MRO shop is unique, but perhaps not for long. MTU Maintenance Zhuhai is currently constructing a second location for maintaining Pratt & Whitney GTF™ engines. And the Munich experts’ assembly concept is under discussion for that facility.

Unique manufacturing technology for assembling new PW1100G-JM engines

At MTU in Munich, a unique manufacturing technology lies behind the assembly of new PW1100G-JM engines that power the A320neo. Since 2016, the Munich site has handled final assembly for 30 percent of all new PW1100G-JM engines. Engines are normally assembled with the help of cranes that run on rails suspended from the ceiling. But the Munich site hit upon an entirely new idea: track-guided assembly. This system features up to 16 remote-controlled carts which, coupled together depending on the stage of assembly, move forward along the assembly line as though on a conveyor belt. There are a total of eight assembly stages, with the pre-assembled components and modules fed in from the side in what could be described as a timed herringbone maneuver. Not only is the system remarkably efficient and flexible, it also has a proven track record. The MTU experts have now also successfully integrated their cart concept into the high-tech assembly system used to maintain Pratt & Whitney GTF™ engines at the EME Aero shop. Continue reading here…